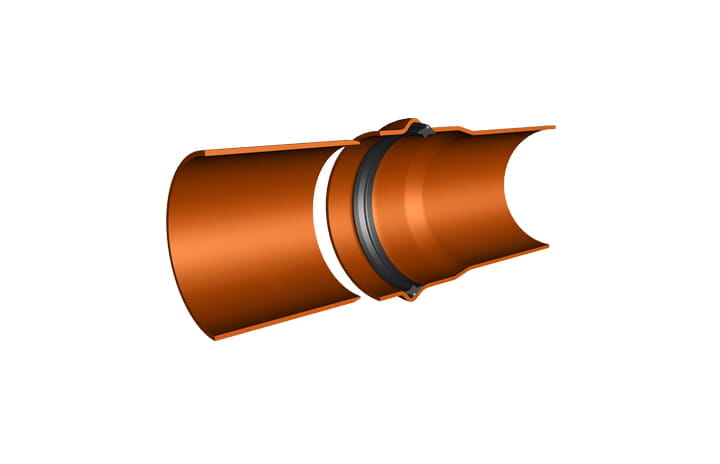

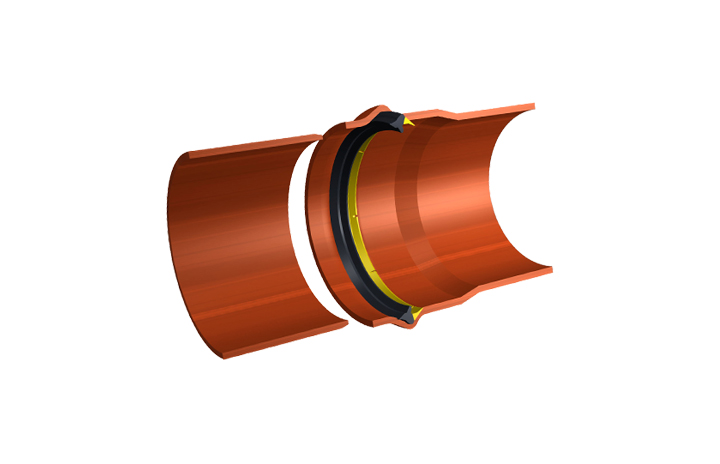

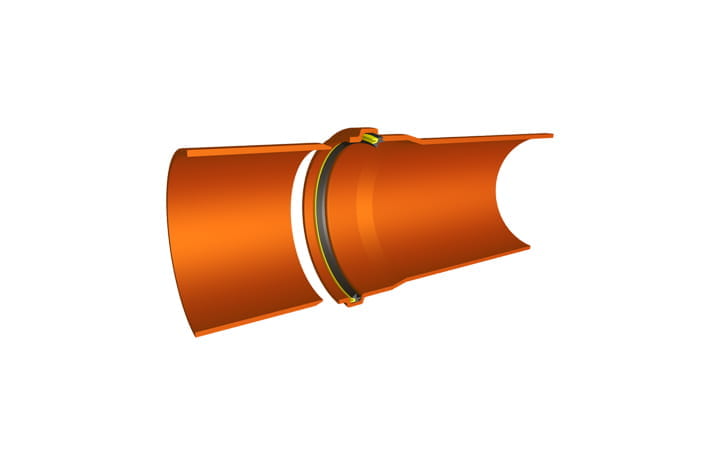

Rieber Sewer seals are integrated into the pipe during the manufacturing process. It uses the mandrel together with the seal as a tool to form the pipe socket. This ensures that the seal always remains in the correct position in the join.

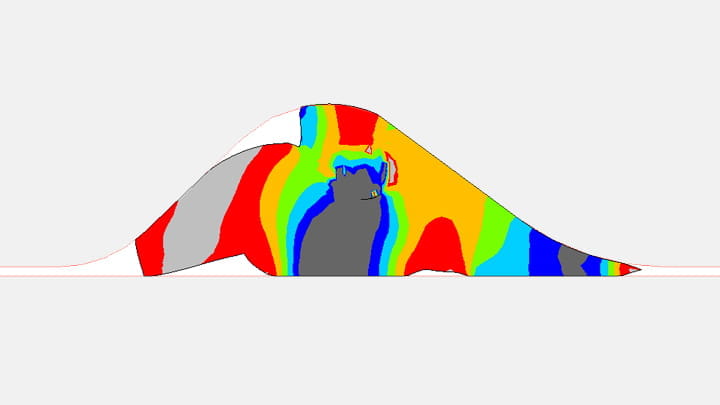

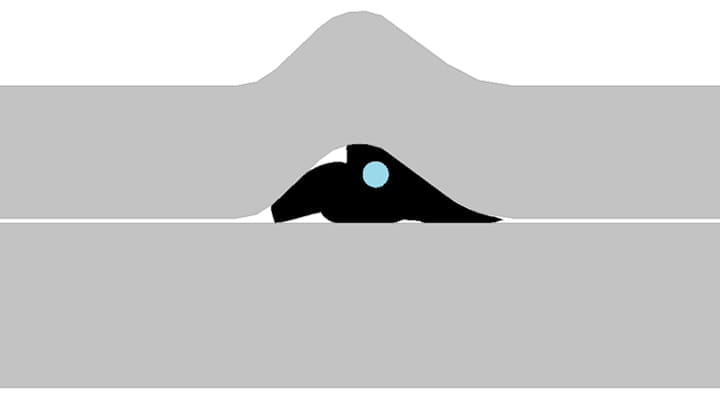

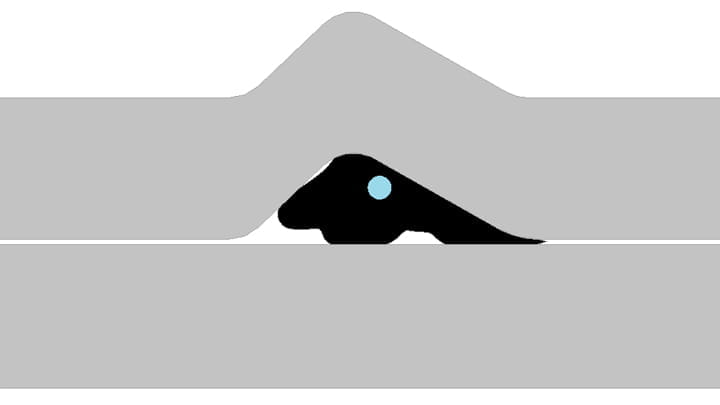

The seals are equally effective under both positive and negative pipe pressure (vacuum). Under positive pressure, the higher the pressure the greater the sealing force. Under vacuum, the seal maintains a positive sealing force against spigot and socket, preventing sand or soil to enter the joint.

The seal comprises a flexible rubber element to seal effectively against spigot and a treated metal insert which holds the seal firmly in place.

Time consuming measurement of pipe sockets and separate installation procedures are no longer necessary. At production, the number of extrusion lines that can be supervised by each operator is greater. This results in productivity increases for both pipe producer and pipe installer.

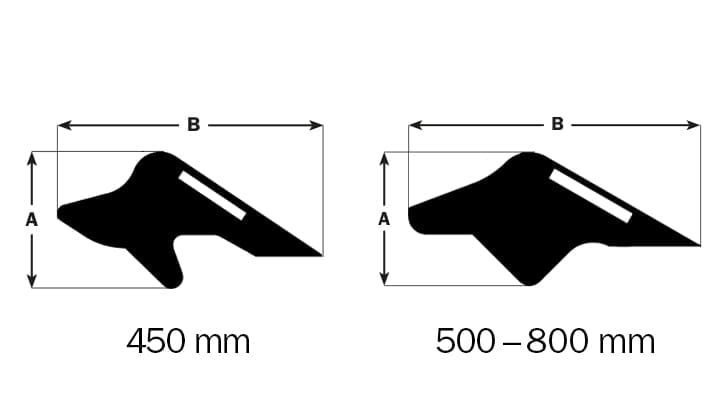

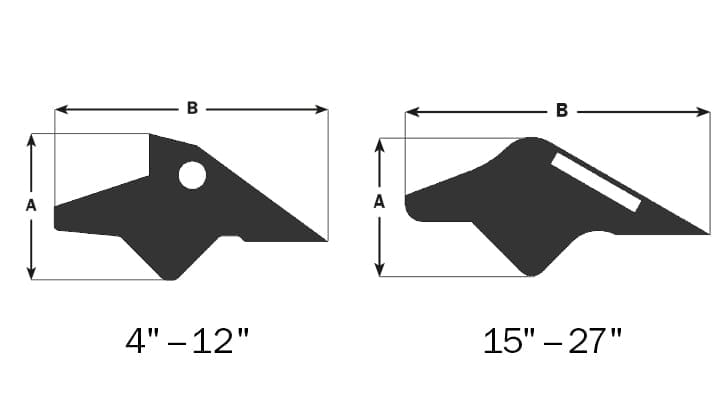

Sizing Chart

| PIPE SIZE (mm) | A (mm) | B (mm) |

|---|---|---|

| 450 | 19 | 37.1 |

| 500 | 22.0 | 48.5 |

| 630 | 22.0 | 48.1 |

| 800 | 24.0 | 52.8 |

| PIPE SIZE (inch) | A (inch) | B (inch) |

| 4 | 0.378 | 0.724 |

| 5 | 0.402 | 0.770 |

| 6 | 0.425 | 0.815 |

| 8 | 0.472 | 0.906 |

| 10 | 0.58 | 1.087 |

| 12 | 0.614 | 1.177 |

| 15 | 0.616 | 1.358 |

| 18 | 0.712 | 1.539 |

| 21 | 0.786 | 1.720 |

| 24 | 0.863 | 1.902 |

| 27 | 0.945 | 2.083 |