Transforming trenchless sewer rehabilitation

In recent years, trenchless sewer rehabilitation has emerged as a highly efficient and cost-effective solution for repairing aging sewer systems. It minimizes excavation and disruption, providing a more sustainable approach to maintaining vast sewer networks, many of which are in urgent need of rehabilitation. Among its most notable innovations is UV light curing, which uses advanced machine technology to deliver precision, speed, and energy efficiency. This article explores the applications, possibilities, and trends of UV machine technology in sewer rehabilitation and how it is shaping the future of infrastructure maintenance.

The advantages of UV light curing

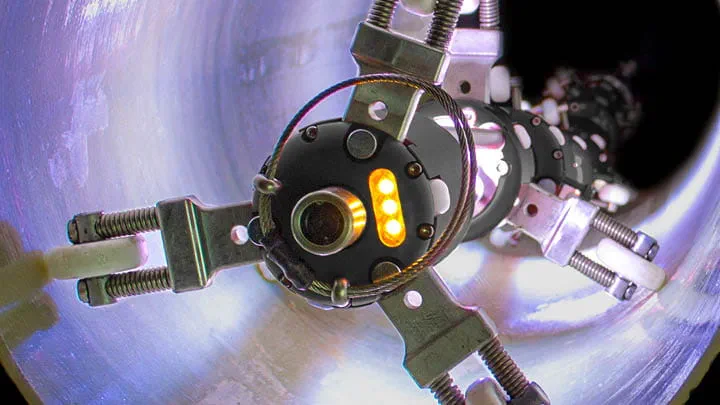

UV light curing has redefined how sewer rehabilitation projects are carried out by addressing key challenges with greater efficiency. One of the outstanding features of this technology is its ability to combine automation and precision. Modern UV curing systems ensure that repair materials are cured evenly and thoroughly, minimizing the inconsistencies that are common in traditional methods. Integrated camera technology takes this a step further by providing a preliminary inspection, allowing defects to be identified and rectified before the curing process even begins. This proactive approach significantly reduces the risk of costly post-curing corrections and ensures project reliability from start to finish.

Speed and efficiency in action

Time is often a critical factor in sewer rehabilitation, especially in urban areas where disruptions can inconvenience thousands of people. UV light curing excels in this regard by drastically reducing curing durations. Unlike steam curing, which is more time-intensive, UV systems complete the process quickly, lowering project costs and minimizing service interruptions.

In addition to its speed, UV light curing is a remarkably energy-efficient process. It requires significantly less energy than steam curing, which translates into lower operating costs and a smaller environmental footprint.

Another advantage lies in the reduced thermal stress that UV curing imposes on pipes and surrounding components compared to conventional curing processes. Operating at lower temperatures, this method protects the structural integrity of the infrastructure, ensuring that both the rehabilitated pipes and adjacent systems remain undamaged.

Designed for flexibility and safety

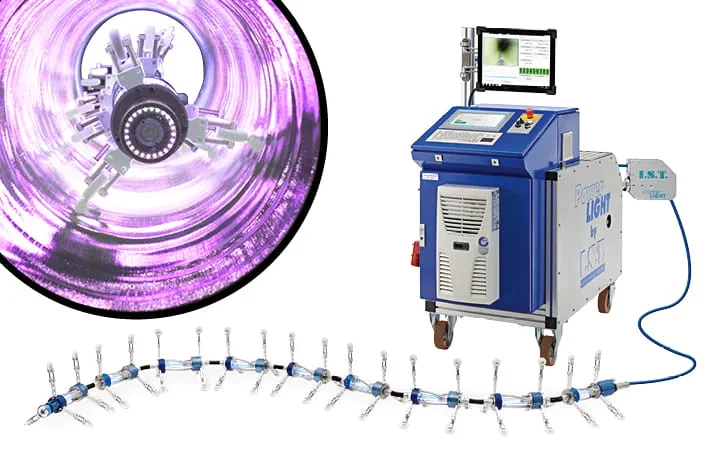

Flexibility is a defining feature of UV curing systems, making them suitable for a wide variety of project requirements. Whether dealing with narrow or hard-to-reach pipe sections or accommodating varying pipe lengths and diameters, these systems adapt effortlessly. Modular designs and customizable components, such as light chains or cores, enable rapid adjustments to meet the specific needs of each project.

Safety is another critical area where UV curing outperforms traditional methods. Steam curing, with its high temperatures and pressurized systems, poses significant risks to personnel. UV curing eliminates these hazards, creating a safer working environment. This not only protects workers but also increases confidence in the technology as a reliable tool for modern infrastructure maintenance.

The compact and mobile nature of UV curing machines further enhances their practicality. These systems are easy to use in confined spaces or hard-to-reach locations. Whether installed as mobile units or integrated into vehicles, they offer better flexibility and convenience compared to bulkier alternatives such as steam-curing equipment.

The more sustainable choice

From an environmental perspective, UV curing offers clear advantages. Unlike water curing methods, which require significant water consumption and disposal, UV systems operate without such demands. Their lower CO₂ emissions further reduce the environmental impact of sewer rehabilitation projects, making them a more sustainable choice.

UV technology also ensures that rehabilitated pipes achieve ideal strength and durability. Consistent curing improves material performance, extending the life of the infrastructure and reducing the need for frequent repairs. This long-term reliability translates into significant cost savings and ensures consistent, dependable performance.

Advancing UV technology

The latest advancements in UV machine technology further solidify its role as a game changer in trenchless sewer rehabilitation. Modern systems integrate documentation capabilities that link curing data with video footage of the process. This comprehensive record provides transparency and serves as a valuable resource for both service providers and customers. Remote maintenance features, enabled by Wi-Fi connectivity and booster technology for performance upgrades, are examples of innovative features that increase efficiency and reliability.

The versatility of UV machine technology is evident in a variety of sewer rehabilitation applications. Urban centers benefit from the fast turnaround times and reduced disruption that UV systems provide. Rural areas, often characterized by difficult access, benefit from the compact and adaptable nature of UV machines. In addition, projects that require the rehabilitation of pipes with varying diameters or unusual configurations are easily addressed with the customizable components of UV technology.

As infrastructure demands increase, the adoption of UV curing technology will continue to grow. Key trends include increased automation, the integration of advanced data analytics for predictive maintenance, and the development of even more energy-efficient systems. With continued innovation, UV technology is poised to expand its applications beyond sewer rehabilitation and potentially impact other areas of infrastructure maintenance.

For more information contact: