Materials for profile extrusion

We work with a variety of polymer-based compounds to create high-quality extruded profiles. These materials range from thermoplastics and thermoplastic elastomers (TPE) to thermoset elastomers, each offering unique properties to meet specific application requirements. Below, you’ll find an overview of some of the key materials we use.

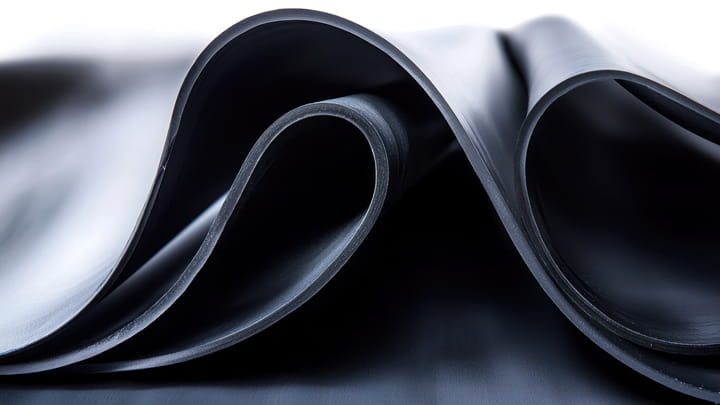

EPDM (Ethylene Propylene Diene Monomer) is a high-performance synthetic rubber known for its exceptional resistance to weathering, ozone, UV radiation, and temperatures. Its durability and flexibility make it an ideal material for sealing profiles in demanding environments.

Benefits of EPDM sealing profiles

- Weather & UV resistance: Perfect for outdoor applications in the building, construction, and renewable energy sectors.

- Thermal stability: Maintains elasticity in a wide temperature range, ideal for automotive and building and construction environments.

- Excellent sealing performance: Provides long-lasting protection against air, water, and dust infiltration.

- Chemical resistance: Withstands exposure to many acids and alkalis.

- Sustainability: EPDM supports long product life cycles, making it a valuable material for eco-conscious industries. Recycling possibilities for EPDM products are increasing, and compounds containing recycled ingredients are already available on the market.

Our custom-designed EPDM profiles are engineered to meet the specific sealing needs of each industry we serve, ensuring performance, reliability, and longevity.

TSP refers to sealing profiles made from thermoplastic elastomers (TPEs), which combine the processing advantages of plastics with the flexibility of rubber. These materials are ideal for precision-engineered sealing solutions across industries such as automotive, construction and renewable energy.

Benefits of TPE sealing profiles:

- Lightweight & flexible: Easy to handle and install, even in complex geometries.

- Recyclable & Eco-friendly: TPEs are available with recycled content, enabling more environmentally friendly products and applications.

- Consistent quality: Thermoplastic processing ensures uniformity and tight tolerances.

- Weather & UV resistance: Offers good resistance to UV exposure and weathering

,and can be enhanced with additives for higher performance. - Customizable properties: TPEs can be multi-extruded (up to four materials in one profile) for added functionality and enhanced design flexibility. They can also be individually colored and modified to create functional surfaces, such as low friction.

Our TPE profiles are engineered to deliver high-performance sealing, tailored to meet the specific demands of each application.

Silicone rubber is a high-performance elastomer known for its outstanding thermal stability, flexibility, and resistance to environmental extremes. Its unique molecular structure makes it ideal for sealing applications in industries that demand reliability under harsh conditions.

Benefits of silicone sealing profiles:

- Wide temperature resistance: Performs reliably from -60°C to +200°C (-76° F to +392° F), making it ideal for aerospace and automotive environments.

- Excellent UV & ozone resistance: Perfect for outdoor applications in construction and renewable energy sectors.

- Non-reactive & chemically stable: Suitable for sensitive environments, including cleanrooms and medical-grade applications.

- Long-term elasticity: Maintains flexibility and sealing performance over time, even under compression.

- Flame retardant options: Available in formulations that meet fire safety standards for critical applications.

- Color & transparency options: Can be customized for aesthetic or functional purposes.

Our silicone profiles are engineered to deliver superior sealing performance in the most demanding environments, ensuring safety, durability, and efficiency.

Soft PVC is a versatile and durable material known for its excellent flexibility, chemical resistance, and cost-effectiveness. Its adaptable nature makes it ideal for a wide range of sealing applications across various industries, ensuring reliable performance in diverse environments.

Benefits of PVC sealing profiles:

- Flexibility & versatility: Soft PVC is highly flexible, making it suitable for a wide range of applications, including complex geometries and tight spaces.

- Durability: It offers good durability, which makes it ideal for basic applications such as interior doors or similar uses.

- Chemical resistance: Soft PVC is resistant to many chemicals, including acids, alkalis, and salts, ensuring reliable performance in various environments. Additionally, it offers inherent flame-retardant properties.

- Applications: It is widely used in indoor applications due to its smooth surface, which makes it easier to clean than other extrusion materials. It can also be individually colored to match specific environments, such as interior doors.

- Cost-effective: Soft PVC offers an affordable, functional alternative to other high-performance materials.

- Ease of processing: It can be easily processed and molded into various shapes, enabling customized sealing solutions, including multi-material extrusion like TPE.

- Recyclable & environmentally friendly: Soft PVC can be recycled, supporting sustainable manufacturing practices and reducing environmental impact. Furthermore, modern PVC compounds contain fewer hazardous ingredients, making them suitable for state-of-the-art applications.

Our PVC profiles are engineered to provide versatile and cost-effective sealing solutions, combining durability, chemical resistance, and ease of processing to meet a wide range of application requirements.

For more information contact:

Bernhard Haass

Development Director Profiles EMEA & APAC

Mike Shutack

Sales Director Americas