Flying high

Nina Winters remembers sitting on the roof of her childhood home, a stone’s throw from Birmingham International Airport, watching the planes take off and land. “Everyone got excited when a Concorde flew in to refuel,” Winters recalls. “The whole house would rattle.”

Now, as the leader of a New Product Introduction (NPI) team, Winters still has her eye on the sky. “Aerospace is an industry experiencing favorable growth and Trelleborg has a particular focus on it moving forward,” she says.

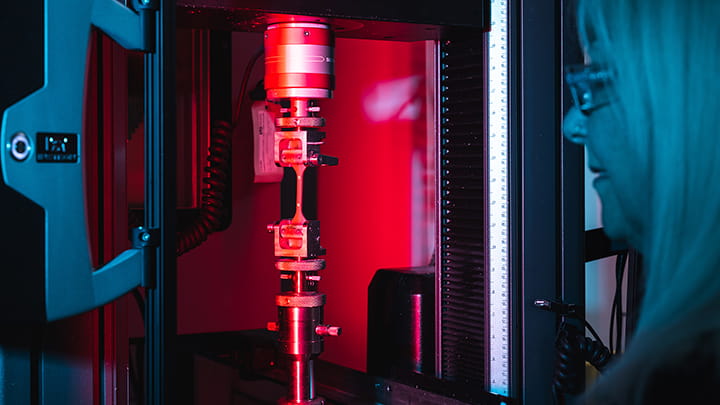

In response to this, her team at the Cadley Hill facility in England has grown, as has the site itself, which now includes a qualification test lab. The team is developing an in-house capability to test end products so that Trelleborg can offer aerospace customers a onestop shop.

For more than 80 years Trelleborg has delivered aerodynamic seals, bearings and other components used in the interior and exterior of an aircraft, from engines, brakes and landing gear to window and door seals, fabrics and coated materials for escape slides.

Some of the most exciting new business is in the realm of green aviation. The aerospace industry is working hard to reduce its reliance on fossil fuels, improve fuel efficiency and test alternative propulsion systems, such as hydrogen, to make air travel more sustainable.

The aerospace team works with customers to optimize the design of aircraft components and find innovative ways to improve fuel efficiency. Measures include reducing aircraft weight by replacing heavier metals with composites. The aerospace team at Trelleborg develops lighter components with composites, silicone and fabrics that provide a low-friction surface to a seal.

“The challenge is to create lighter-weight, heat-resistant materials that tolerate the higher temperatures generated in newer, more-efficient engines,” Winters says. “Fresh technologies are coming along in the aircraft industry, which is interesting and motivating for the whole team.”

The NPI team is looking at solutions for one of the most exciting innovations on the green aviation horizon, Urban Air Mobility.

This includes electric, potentially pilotless air taxis for use in urban areas. These semi-autonomous vehicles, also known as electric vertical takeoff and landing (eVTOL) aircraft, will ultimately carry people.

“The smaller ones can be electrified, and the hope is that they will be widely used and reach similar levels to car production,” Winters says. “Seals will be required on all those air vehicles, so there will be big opportunities for us as a company.”

So far, the aerospace team has supplied new seals and grommets to a leading US-based eVTOL developer, and it is working on a range of fire protection and containment seals and gaskets for a similar company in Germany.

In 2022, the team also worked on components for the next generation of engines, which are 25 percent more fuel-efficient than earlier models. The engines will be used to test and develop solutions for sustainable air travel.

Although Winters has an affinity for airplanes, she hasn’t always worked in aerospace. She started as a development technologist in the lab at Woodville Polymer.

When Trelleborg acquired Woodville in 2001, Winters joined the company and ran a lab that developed formulas and materials for rubber mixtures. During that time Trelleborg expanded its aerospace business and Winters moved to work exclusively on aerospace — that is, until another opportunity arose. She has had several other roles within Trelleborg and worked in Malta, Paris, Shanghai and Boston before moving back to England.

More recently, she also took on managing the integration of a newly acquired German aerospace company based in Lindau. This role brings her in touch with many new people and functions, everything from the installation of IT infrastructure to the correct use of branding.

It is this range of roles and experiences that has kept Nina Winters at Trelleborg for more than 25 years. “Aerospace is never repetitive, in particular because each new airframe product is bespoke,” she says.

As a child in Birmingham, Winters once saw a Boeing 747 descend with a space shuttle attached. Another time she watched Air Force One land with President Bill Clinton on his way to a G8 summit.

Today, Winters is flying in new iterations of the planes she watched as a child. When she takes her seat and looks out the window, she can spot the aerospace team’s work on the wings, and inside the aircraft as well. “It’s nice to see what we’remaking,” she says, “and know that it’s important to the safety and performance of the plane.”

This is an article has been reproduced from Trelleborg's T-Time magazine. To download the latest edition, go to: www.trelleborg.com/t-time