In Good Taste

Date: 23.04.21

Glancing at the supermarket shelves reveals the wide variety of beverages for sale; a colorful assortment of flavors based on current trends, target groups and seasonal changes. Making sure they all taste as they should is vital. A collaboration between Trelleborg Sealing Solutions and Krones, a specialist in components and lines for beverages, makes sure this goal is met. -By Meghan Cloud Braunger

IN SHORT

- Flavor carryover poses a real threat to beverage companies.

- Trelleborg Sealing Solutions partnered with Krones to identify the cause of, and find solutions to this.

- Sealing material selection proved to be key in ensuring beverages taste as they should.

IT’S CHALLENGING FOR BEVERAGE COMPANIES TO MEET THE REQUIREMENTS

of a market driven by consumer demand. Products are modified rapidly and industry experts predict the beverage market will continue to evolve at increasing speed. Optimizing production, enhancing efficiency and flexibility, as well as maintaining the highest quality standards and food safety, are essential. More and diverse product lines mean manufacturing times are shorter and production changes more frequent. One issue with this is the risk of flavor carryover.

Elastomer sealing components were believed to be a relevant factor in aroma carryover. The selection of an optimum sealing material would potentially be crucial in preventing the transfer of flavors from one filling process to the next. Based on this hypothesis, Trelleborg Sealing Solutions partnered with Krones, a specialist in the beverage bottling process, to analyze the reasons behind unintentional flavor carryover related to seals during the filling process.

Dr. Eva Beierle, Development Engineer Aseptic and Process Technology at Krones, understands the aroma carryover issue from the bottlers' point of view. She says: "One trend in the latest beverages is toward increasingly intense flavors. This poses challenges, since beverages with high concentrations of flavors naturally tend to leave perceptible traces of aroma in the bottling lines

Sealing relevant in aroma carryover

Elastomer sealing components were believed to be a relevant factor in aroma carryover. The selection of an optimum sealing material would potentially be crucial in preventing the transfer of flavors from one filling process to the next. Based on this hypothesis, Trelleborg Sealing Solutions partnered with Krones, a specialist in the beverage bottling process, to analyze the reasons behind unintentional flavor carryover related to seals during the filling process.

Dr. Eva Beierle, Development Engineer Aseptic and Process Technology at Krones, understands the aroma carryover issue from the bottlers' point of view. She says: "One trend in the latest beverages is toward increasingly intense flavors. This poses challenges, since beverages with high concentrations of flavors naturally tend to leave perceptible traces of aroma in the bottling lines

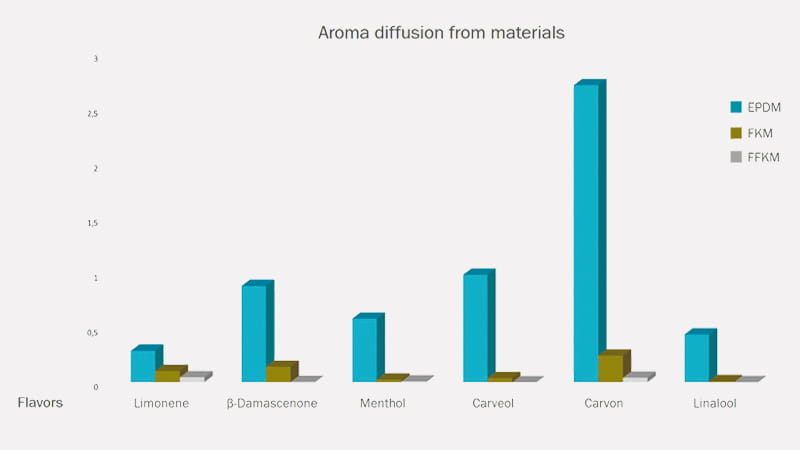

Aroma diffusion from materials

EPDM, FKM and FFKM materials were tested with numerous aromas to determine which materials were most effective in preventing carryover.

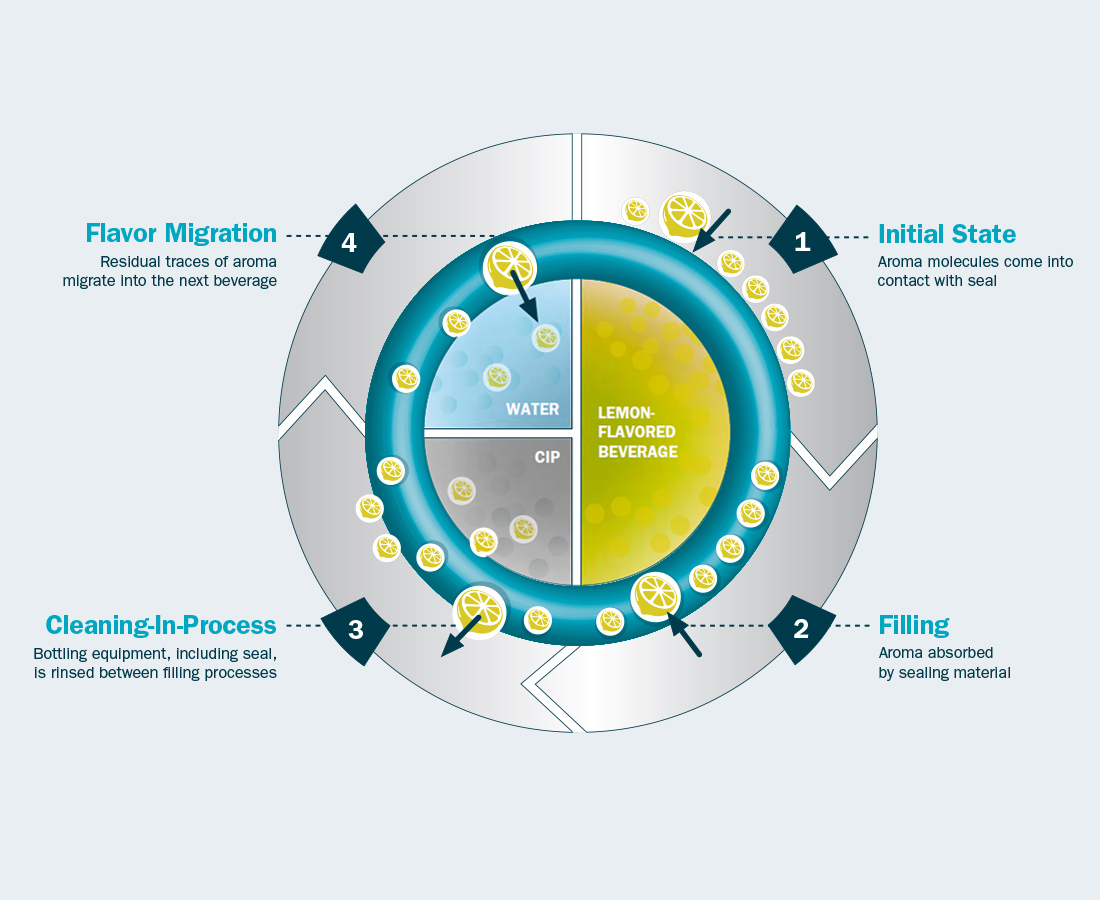

WHAT IS FLAVOR CARRYOVER

Flavor carryover is the transfer of flavors from one filling process to the next. Despite cleaning measures and adapted production plans, small traces of aroma can remain in the bottling machines, which can then be absorbed by the next beverage. This danger should not be underestimated, especially when intense flavorings are used.

The consequences of flavor carryover are product rejects, unintentional downtime, additional inspections and complaints. In the worst case, it can even lead to recalls, closures and fines.

ABOUT KRONES: AN ALL-ROUND PARTNER FOR THE BEVERAGE AND LIQUID-FOOD INDUSTRY

Whether made of glass, PET or aluminum – Krones machines and lines process millions of bottles, cans and specially shaped bottles each day. Its customers mainly comprise breweries, water, soft drink and juice manufacturers, as well as dairies and producers of wine, sparkling wine and spirits, and companies from the liquid-food field.

FoodPro™ High-performance elastomer and plastic material range for the Food & Beverage industry

SUSTAINABILITY HIGHLIGHTED AT VIRTUAL CONFERENCE EUROPE

The joint Trelleborg Sealing Solutions and Krones project was featured at the Trelleborg Sealing Solutions Virtual Conference on November 25, 2020. Dr. Eva Beierle, the lead engineer at Krones involved in the aroma carryover R&D project, joined Konrad Saur as a guest speaker in the panel discussion “Engineering Towards a More Sustainable Future.”

Also participating in the sustainability session were Marina Ponti, Global Director of United Nations SDG Action Campaign and keynote speaker Dr. Will Ritzau, Professor for Digital Business Management & Sustainability at University Fresenius in Germany.

Also participating in the sustainability session were Marina Ponti, Global Director of United Nations SDG Action Campaign and keynote speaker Dr. Will Ritzau, Professor for Digital Business Management & Sustainability at University Fresenius in Germany.