Predictive Maintenance - A Service Ecosystem Is Emerging

Today, the service portfolio of industrial firms is still largely dominated by classical industrial services such as maintenance, repair, and spare part supply. Digitalization, which has significantly changed our social lives, has also reached the service sector and will change it dramatically.

Cheaper and almost unlimited computation power in the cloud, faster and ubiquitous internet connectivity, and low-cost electronics create completely new possibilities for industrial services through the Internet of Things (IoT). With the connectivity provided by IoT, Original Equipment

Manufacturers (OEMs) can communicate with the machines installed at their customers’ sites. They can – if the customers want it – keep an eye on technical parameters and intervene in machine processes, if necessary. They can offer their customers condition monitoring, remote diagnosis, remote maintenance, and teleconsulting.

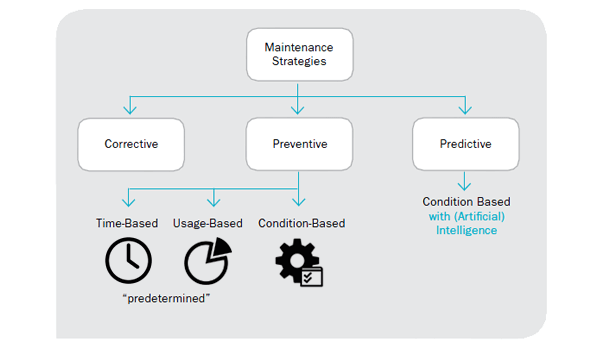

A real breakthrough, however, is achieved when connectivity is combined with artificial intelligence. The most promising application of this type is predictive maintenance. Predictive maintenance should not to be confused with preventive maintenance, which is done in regular intervals based on time, usage or condition (see Figure 1). Instead, predictive maintenance builds on condition monitoring and uses intelligent algorithms to predict the impending occurrence of a machine failure when certain condition changes have been detected.

Maintenance can now be scheduled flexibly within a remaining time interval before a failure occurs. Timely proactive maintenance prevents damages and expensive machine downtime. It leads to an overall cost reduction and efficiency increase. There are testimonials that show that predictive maintenance yields cost savings of over 55 percent over preventive maintenance and nearly 70 percent over reactive maintenance. No wonder predictive maintenance is on everyone’s lips today.

BIOGRAPHY

In the mid-1990s, Hansjörg Fromm forged the business area Supply Chain Management within IBM Global Business Services. In 2006, he was appointed European Head of the IBM Centers for Business Optimization (CBO).

Hansjörg Fromm has been lecturer at the University of Nuremberg-Erlangen. In 1993, he was appointed honorary professor and elected as a member of the IBM Academy of Technology (an international circle of about 200 IBM scientists) and appointed IBM Distinguished Engineer.

From July 2011 until July 2014, Prof. Fromm was director of Karlsruhe Service Research Institute (KSRI) at the Karlsruhe Institute of Technology (KIT) and head of the research group Service Innovation and Management. After his retirement from IBM, Hansjörg Fromm remains dedicated to KSRI as an honorary professor.