Research & Development in Clermont-Ferrand

For some outdoor applications, this not only affects the handling of the hose but its lifespan.

But just how stiff?

While there are many ways to measure the stiffness of polymeric materials at low temperatures, until recently there hasn’t been a good way to test the flexibility of a cold multilayer hose.

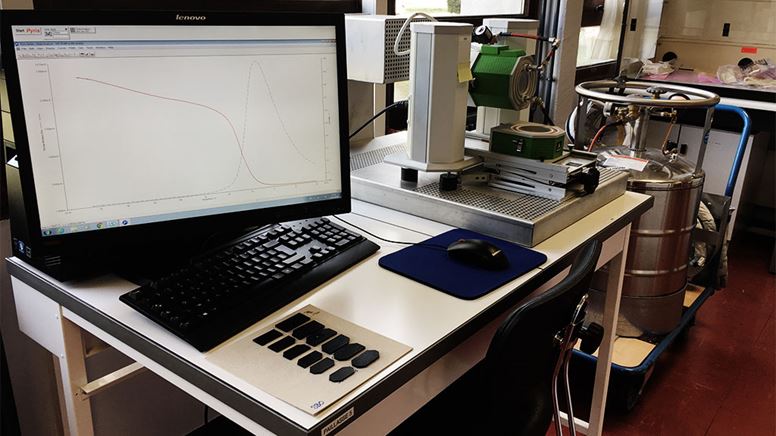

Now, however, at Trelleborg’s labs in Clermont Ferrand, we have developed a dynamic mechanical analyzer so it can test flexibility against temperatures all the way down to -180°C.

This test method gives you relevant information regarding flexibility versus temperature under dynamic solicitation (frequency 1-50hz) and makes it possible to compare the flexibility of polymeric materials moduling on cooling to the hose’s bending strength at the same temperature.

Our next step: develop a mechanical model to determine the highest modulus needed to keep the flexibility of the hose according to customer requirements or international standards.