Embracing electric vehicles in the construction industry

EVs, construction and the energy transition

The transition from internal combustion engines (ICEs) to electric motors aligns with global efforts to reduce reliance on fossil fuels and transition to more renewable energy sources.

Companies around the world are working towards net zero targets and the construction industry is no different. From zero emissions construction sites to embracing electric heavy machinery.

Off-highway EVs – market share and growth potential

The data around EVs in the construction industry demonstrates a growing trend. When it comes to van fleets, electric vehicles already make up around 5.2% of the market share.1 This will grow exponentially in the coming years as many EU countries work to end the sale of new ICE road vehicles.

By comparison, replacement of off-highway ICEs has been far slower. But that’s all set to change. By 2044, the electric construction vehicle market is set to grow to USD 126 billion – representing 21% growth in the next 20 years (CAGR).1

Market-ready or under construction?

Benefits of EVs for the construction industry

Electric construction equipment has the power to transform the way you work. With the benefit of zero emissions, high performance and low noise, electric machines are the perfect partner to make any construction project more sustainable. Especially when paired with antivibration solutions that further reduce maintenance and improve longevity.

✅ Significantly reduce CO2 emissions

✅ Reduce noise

✅ Improve TCO

✅ Save on maintenance

Despite numerous benefits and clear demand from stakeholders, adoption remains slow across the industry. So what are the barriers?

Challenges and barriers to adoption

Adoption is often delayed by reluctance to retire perfectly good legacy equipment, the upfront costs to purchase EVs, operator buy-in and the inconvenience of onboarding and training. Equally, the comfort of off-highway vehicles is a fine balance that impacts both safety and productivity – the shift to electric vehicles will feel risky to many businesses who have achieved this using ICEs.

❌ Higher upfront costs

❌ Retirement of existing vehicles

❌ Operator buy-in, onboarding and training

❌ The risk of reducing comfort

Smoothing the transition

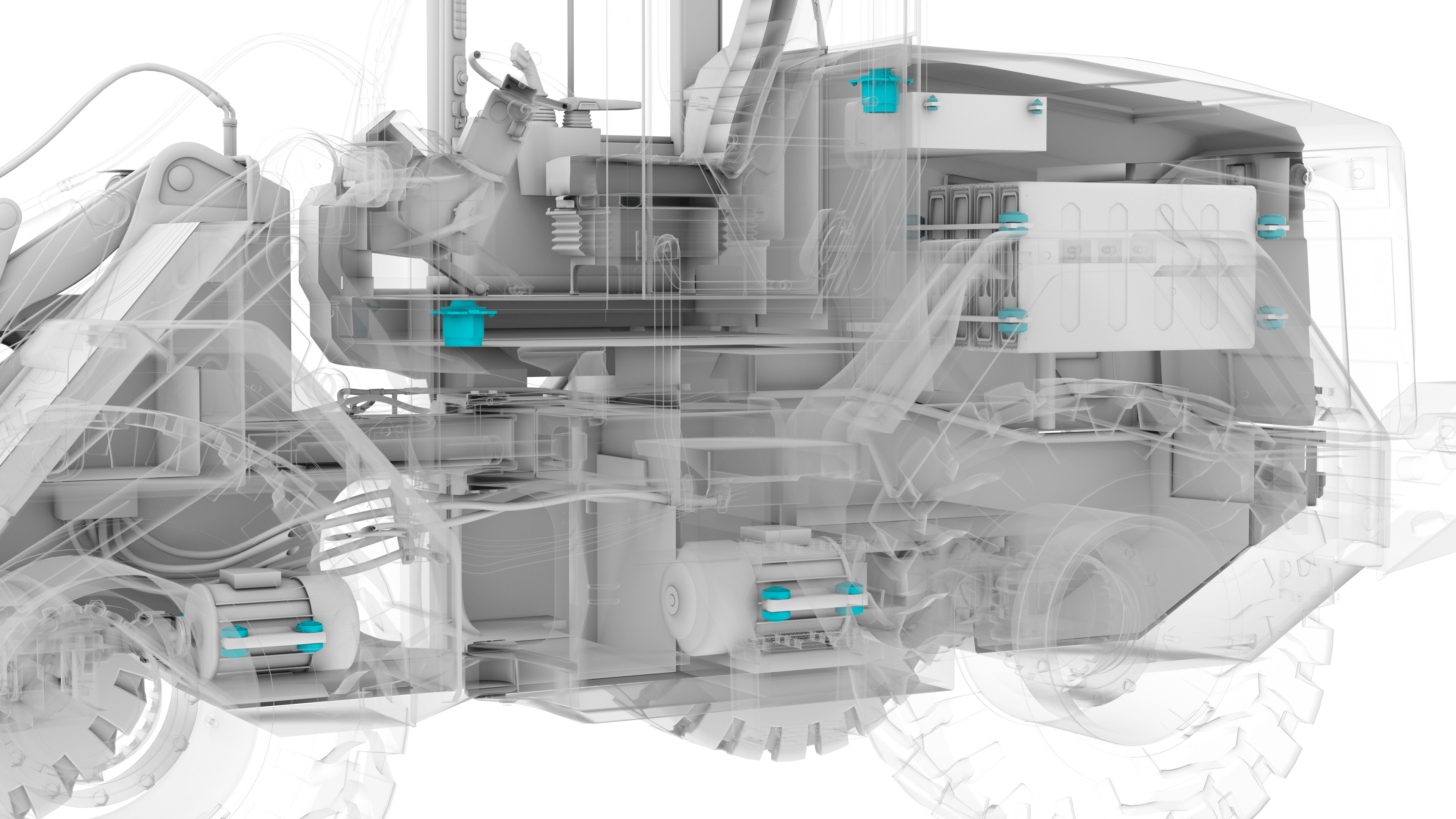

Unlike traditional ICEs, electric motors generate unique structural vibrations that require specialized isolation. Without optimal vibration management, EV construction equipment can face increased wear, reduced comfort, and accelerated degradation of critical components, including batteries and inverters. Our customized mounts are engineered to address these issues, providing:

Enhanced comfort and stability

Minimize unwanted movement, noise and vibrations to improve comfort and safety with customized mounts for motors, transmissions, and other components.

Noise Reduction

Maintain a quieter and more comfortable workspace for operators by isolating both low and high-frequency sounds.

Battery Longevity

Protect your batteries from dynamic loads and vibrations, extending their life and minimizing degradation.

Extended lifecycle

Protect your investment for longer-lasting equipment with reduced repair costs and higher operational uptime.

Trelleborg mounting solutions for EVs

Talk to us about your construction vehicle electrification challenges

Let’s explore your challenges together. Simply fill in the form below and one of our off-highway experts will be in touch.