No Dig, less mess!

Digging up and replacing sewer pipes is a messy, time-consuming and environmentally challenging undertaking. Trelleborg offers solutions that can make the process easier, less expensive and more environmentally friendly.

The old expression “out of sight, out of mind” applied for many years to municipal sewer systems. While local governments could see aboveground infrastructure issues that needed to be addressed, such as deteriorating roads and bridges, problems with crumbling sewer systems could not be seen and so were often ignored.

That’s all been changing in recent years with the increased emphasis on water quality and water treatment issues in the industrial world. Deteriorating sewer pipes lead to two major environmental issues. The first is that infiltration of ground water into pipes means increased water flow and a heavier workload for municipal treatment plants. In times of heavy storms, plants cannot handle the flow and raw sewage is often discharged into waterways, adding to local water pollution. The second issue is exfiltration, namely materials leaking out of sewer pipes into the groundwater supply, causing pollution.

The scale of the problem is massive.

In the United States, for example, the Environmental Protection Agency estimates there are about 600,000 miles of sewer pipe, of which 75 percent operate at less than 50 percent of capacity because of deterioration issues. Germany, as another example, has 500,000 kilometers (roughly 300,000 miles) of sewer pipe and an additional 1 million kilometers of lateral pipes – pipes that branch off from main sewer lines to individual housing units.

Awareness of the problem has been growing,” says Andreas Bichler, R&D Director within Trelleborg Pipe Seals. “Yet replacing deteriorating pipe can be expensive and highly disruptive to the environment and the local economy."

Trenchless rehab

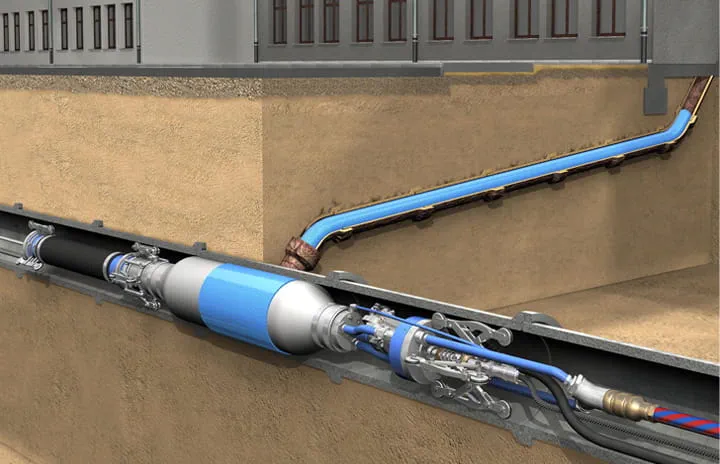

Trelleborg’s trenchless, no-dig pipe technology offers solutions which provide minimal disruption to the community, traffic, environment etc. and are often a lower overall cost alternative to complete pipe replacement.

"Trelleborg technology can be used to line pipes, essentially sealing them from the inside, and can be installed from manhole to manhole, meaning there’s no need to rip up streets, causing environmental pollution and delaying traffic", notes Tim Sparrow, Sales Director US for the pipe seals operation. “More and more cities are looking to trenchless technology to rehabilitate and extend the service life of existing pipelines,” he says.

Overall costs can be significantly lowered by using trenchless technology.

When the cost of replacing the road above a sewerage system is included, the cost of digging up and replacing a section of lateral sewer pipe could be tens of thousands of Euros / Dollars. Lining a pipe instead, could result in cost savings of between 20 and 50 percent.

Trelleborg has also tackled the issue of sealing lateral pipes from the street so there’s no need to go into property owners’ homes or to rip up their yards to replace pipes, Sparrow says. In the United States, Trelleborg’s “Main to House, MtH” technology has been employed by Carylon Corp. for the more than 6 years.

The town of Norwood, Massachusetts has a leaking sewer system which was polluting the surrounding ground water, as such they decided to line laterals all the way to the property.

The result was a significant drop in the bacteria levels of the local groundwater, to the extent that Trelleborg and Carylon Corp, were invited to EPA headquarters in Washington, D.C., to provide a technical presentation on the technology now available in the marketplace to address such issues.

Trelleborg continues to work on its trenchless technology to adapt it for more markets. "Places such as Singapore and Australia, for example, have sewer pipes that are smaller in diameter than those in the United States", Andreas Bichler notes.

"Trelleborg has designed smaller installation equipment for such systems and is currently field-testing it. It is also working with materials that will allow lining pipes with multiple 90-degree bends and changes in internal diameter", he says.