Key Benefits

Application Expertise

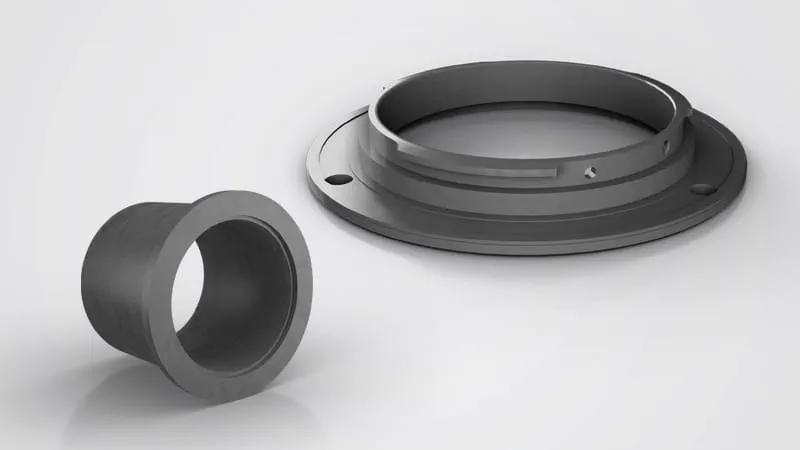

Hydraulics and Actuation

Trelleborg Sealing Solutions manufactures a wide range of thermoplastic components, from scrapers and gears, to bushings and piston rings. Our solutions withstand high pressures and loads to give long service life.

- Low friction – for smoother movement and reduced wear

- Consolidate functions – combine into a single component

- Add or enhance properties – such as damping and wear

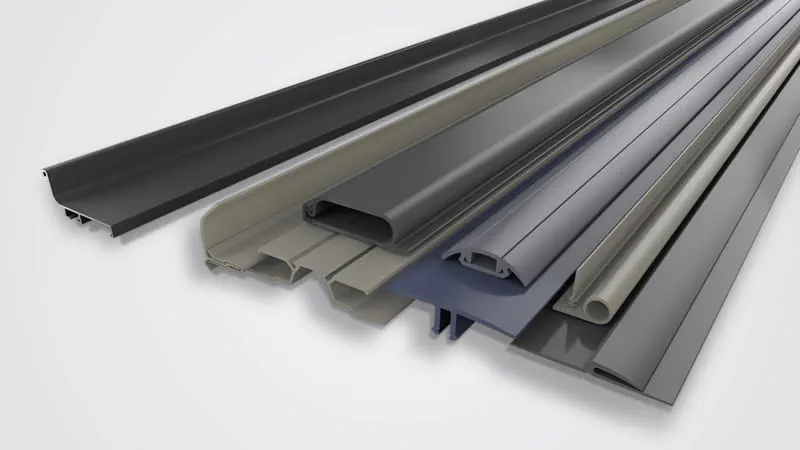

Structural

Manufactured using the latest techniques, structural components can take many shapes and forms to reduce the footprint of components

- Light – up to 40% lighter than aluminium, 55% lighter than titanium and 70% lighter than steel

- Strong – resilient and highly resistant to impact

- Reduce assembly steps – lowering total cost of ownership and wear

High specification materials can replace metallic components to reduce weight without compromising on resilience. They withstand high temperatures and resist harsh chemical environments to improve product lifetime.

- Heat resistant – from -40 °C to +260 °C / -40 °F to +500 °F

- Media compatible – materials to support all common fluids, including oils, coolant and fuels.

- Lightweight – save fuel and increase efficiency

Thermoplastics offer engineers wide latitude in their designs. Excellent strength-to-weight ratios and easy manufacturability allow new shapes for aesthetics or to increase aircraft capacity.

- Reduce frame sizes – fit more seats and more passengers

- Bespoke interior trim/accents – wide range of colors and meet smoke and fire safety requirements

High Performance Thermoplastics Technology and Development Center

Our core values – customer focus, performance, innovation, and responsibility – are long-term commitments.

Our Advanced Technology Center develops high-performance, novel compounds with complementary design and processing competence. The center focuses on formulating custom materials and products to combine both areas of expertise. We develop and refine our portfolio of materials, capabilities, and products to ensure we can support our customers, whatever their requirements.

Specially for thermoplastics, we offer:

Our Advanced Technology Center develops high-performance, novel compounds with complementary design and processing competence. The center focuses on formulating custom materials and products to combine both areas of expertise. We develop and refine our portfolio of materials, capabilities, and products to ensure we can support our customers, whatever their requirements.

Specially for thermoplastics, we offer:

- Custom polymer blending - material optimization for: wear resistance, temperature profiles, strength and electrical properties

- AI and Computation Engineering optimized design services – revolutionizing product development

- Lubrication additives, including PTFE, graphite and MoS2

- Customer application testing and support

- Material characterization and analytical assistance