Automotive

Key takeaways:

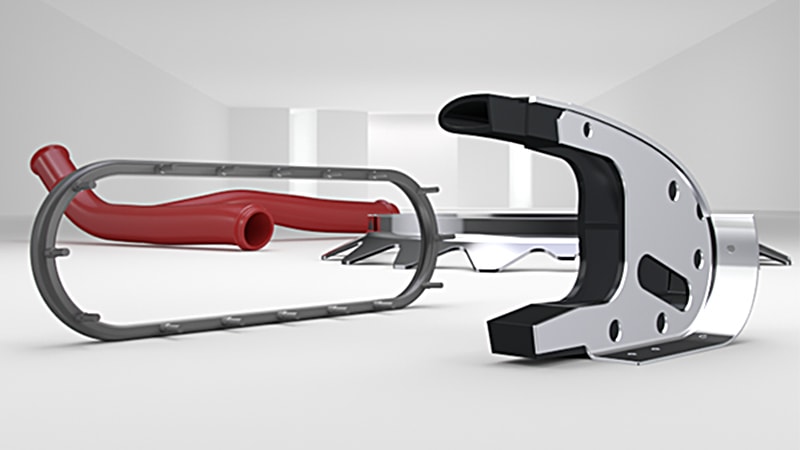

- Where D-Seal can be used to prevent cavitation damage

- Why its design can improve performance in automotive applications

- How Trelleborg’s material range can meet your requirements

- Understand the challenges posed by corrosion intrusion and propagation and why these are crucial for battery fixations and threaded fasteners

- Discover Rubore® laminates, strongly bonded rubber and metal layers, which offer effective sealing to prevent corrosion from entering battery housing

- Find out how Trelleborg ensures fast lead times for both prototypes and mass production, enabling efficient development and manufacturing processes

Aerospace

Explore Trelleborg’s wide range of capabilities and products for Advanced Air Mobility (AAM), ranging from cabin & interiors, thermal management to airframe & structures.

Key takeaways:

- Learn about the extensive range of polymer materials and solutions that maximize performance in the most demanding environments

- Discover what makes Trelleborg an ideal partner when developing AAM aircraft for certified flight operations

- Find out about existing technologies as well as new technologies that help accelerate developing AAM aircraft

Discover Trelleborg’s wide range of capabilities and products for aerospace galley applications, including seals, tubing, covers and custom molded parts.

Key takeaways:

- Take an in-depth look at sealing solutions for selected galley applications and gain knowledge on related government regulations and material compliance requirements

- Learn how Trelleborg can support your application design and development process

- Develop and understanding of our manufacturing capabilities and the services we offer to support customers

Find out about Trelleborg’s polymer capabilities and how they are utilized within the aircraft cabin to help solve demanding customer applications.

- Learn about Trelleborg’s comprehensive portfolio of polymer processing capabilities for aircraft cabin components, including extruded thermoplastics and elastomers, injection molded thermoplastics, elastomeric gaskets and seals, and more.

- Discover the polymer materials used within the aircraft cabin, and the processing methods for each

- Understand the regulations and primary customer requirements for thermoplastic and elastomer components used in the cabin of the aircraft

Gain an understanding of Trelleborg’s production and design capabilities and the benefits they can bring to airframe manufacturing.

Key takeaways:

- Find out about Trelleborg’s capabilities and range of materials

- Learn about the complexity and processes involved in fabricating reinforced seals

- See the impact of Design for Manufacture on cost of product without jeopardizing seal performance.

See how Orkot® C620 pushes the boundaries of composite technology, specifically designed and developed to meet the requirements for a strong and light material to withstand high loads and stresses over a long service life in landing gear.

Key takeaways:

- Discover how Orkot® C620 can reduce weight and increase efficiency

- Learn how the material enhances performance

- Understand how it compares with other composite and metallic bearings

Find out about Trelleborg Sealing Solutions simulation capabilities and how they ensure product and sealing components meet aerospace application requirements.

- Learn about seal simulation capabilities, material characterization and verification testing as well as specific capabilities for aerospace products and applications

- Understand how Finite Element Analysis (FEA) can be performed for a wide range of aerospace products, including airframe seals, engine seals and bearings for landing gear

- Learn how Moldflow analysis ensures high quality custom molded parts by analyzing the manufacturing process

Turcon® VL Seal® II is an improved version of Turcon® VL Seal® with improved sealing performance, ease-of-installation and reliability. It integrates a unique and patented back-pumping feature to increase product life.

- Learn about the new features of Turcon® VL Seal® II and how the seal can reduce aircraft maintenance with ‘sealed for life’ components

- Find out about the seal’s back-pumping performance and its contribution to aircraft weight reduction

- Understand installation configurations and the way in which the tandem sealing system enhances flight safety

Find out about UHT Seals, designed and tested to operate at greater efficiency at the temperatures encountered in the next generation of engines.

Key takeaways:

- Learn how and why elastomer seals are evolving to meet new aircraft and engine requirements

- Understand the importance of high temperature functional load testing versus traditional static material testing

- See comprehensive test results verifying performance under load at elevated temperatures and recognize how to achieve better performance with lighter weight and lower system cost

Learn about the Zurcon® Excluder® ESA, a polyurethane scraper for aircraft landing gear, that prevents the ingress of contaminants into the lower bearing of the shock strut at a wide temperature range.

Key takeaways:

- Find out where and how Zurcon® Excluder® ESA is used

- Understand the current portfolio of aerospace products and where Zurcon® Excluder® ESA fits within it

- Explore technical design details, test results and materials

Energy

Key takeaways:

- Understand the unique sealing challenges posed by the numerous applications of the rapidly growing hydrogen sector and how these are addressed by the Trelleborg Sealing Solutions H2Pro™ range

- Find out how Trelleborg Sealing Solutions has overcome the lack of relevant industry standards by developing exclusive testing capabilities to validate materials in challenging real-world application conditions

- Explore the expanding H2Pro™ range of proven sealing materials for hydrogen production, transport and storage, and end-use, detailed in a new brochure and available now

See how Trelleborg’s advanced composites outperform traditional chopped fiber and thermoset composites in aggressive environments, improving efficiency, reducing environmental impact, and extending service life for energy applications.

Key takeaways:

- Learn the advantages of selective reinforcement via Automated Fiber Placement, including complex shapes and customization to accommodate specific loading requirements

- Discuss industry use cases, including composite bearings for low-friction wear applications and shields for structural strength, as well as applications requiring signal transparency

- Find out how high-performance composites can improve efficiency and environmental impact through weight reduction, low friction, wear resistance, and extended service life

Key takeaways:

- Discover how the new H2Pro™ range of fully validated materials is specifically designed to meet the challenging application conditions of the full hydrogen value chain

- Learn about two new materials Zurcon® H2Pro™ ZLT and H2Pro™ EBT25 specifically engineered for challenging hydrogen gas applications such as high pressures or low temperatures

- Find out about the extensive pipeline of further H2Pro™ materials available this year

- Draw on our experts to discuss your hydrogen sealing needs

Discover how SealWelding™ permits replacement of seals in-situ, removing the need for complete disassembly and delivering cost and time savings.

Key takeaways:

- How SealWelding™ reduces down-time, saving on costs and time, with in-situ seal change out

- Why it offers a sustainable solution, decreasing environmental impact

- Where it allows upgrading of existing equipment with innovative Trelleborg designs and materials

Find out about the XploR™ S-Seal and XploR™ FS-Seal spring-energized static seals, specially developed to give leak-free sealing performance under extreme pressures in oil and gas, chemical processing and chemical transport applications.

Key takeaways:

- Discover how the new XploR™ S-Seal and XploR™ FS-Seal can benefit you by simplifying installation and lowering total cost of ownership

- Understand how these seals improve the safety of critical systems in high pressure and temperature environments

- Learn how the flexible one-piece seal design optimizes sealing performance for leak-free applications

Find out how lightweight and strong thermoplastics are ideal to improve efficiency and performance of electrical systems in a range of industries, including Aerospace, Automotive and General Industry.

Key takeaways:

- Learn how thermoplastic composites improve the efficiency and performance of electrical systems, outperforming traditional thermoset composites and metallic structures

- See why Automated Fiber Placement of Thermoplastic Composites is an ideal manufacturing process for composite structures

- Understand why these composites are well-suited for use as electrical insulators and EMI shielding

Food & Beverage Processing

Discover the revolutionary new elastomer sealing material, FoodPro® E75F1, that is compliant with the most comprehensive range of global food contact material regulations and is specifically engineered for universal use in Food & Beverage processing applications.

Key takeaways:

- Learn about the features and benefits of FoodPro® E75F1 and how this material saves time and costs in the food and beverage equipment manufacturing process

- Understand the molding capabilities of this material and the benefits multi-component parts in food and beverage processing

- Find out about the intensive testing process undertaken to prove this material’s compatibility with process and cleaning media used in CIP and SIP cleaning regimes

Key takeaways:

- Find out about the features and benefits of the FoodPro® EPDM family

- Discover how these materials save time and costs in the Food & Beverage equipment manufacturing process

- Understand how we ensure our materials are compliant with regulations and the intensive testing process undertaken to prove compatibility

Trelleborg Medical Solutions

Discover how advanced extrusions, manufactured from high consistency rubber (HCR) silicone, can enable smaller, more intricate and more complicated medical devices.

Key takeaways:

- Get a better understanding of the trends in medical device design

- Find out the value of silicone polymers for medical devices

- Understand how our advanced extrusion technologies can benefit your medical devices, based on several case studies

In this webinar, we will:

- Introduce Trelleborg’s broad range of innovative capabilities targeted for single-use fluid path systems for the biopharmaceutical industry

- Demonstrate how we partner with biopharmaceutical OEMs starting with development of new products, to prototyping, and through to serial production

- Showcase our robust quality system tailored to standards of the biopharmaceutical industry

Discover how introducing active pharmaceuticals to silicone aids in the development of drug-eluting devices and implantable drug delivery systems to create innovative therapies for patients.

Key takeaways:

- Understand market trends, the early uses of drug elution and expectations on the future

- Learn about excipient materials used as well as the manufacturing methods that can be employed

- Gain a detailed breakdown of multiple ways APIs can be introduced to silicone with case studies

Find out about how close cooperation with material suppliers can support medical device manufacturers with EU medical device regulation (MDR) 2017/745 compliance and testing.

Key takeaways:

- Gain an understanding about MDR material related requirements

- Learn how a partner-like approach helps you identify and fulfil these demands

- Understand requirements and solution approaches with Trelleborg experts

Attendees will gain a better understanding of rubber component design and manufacturing – from material selection to prototyping and production-ready mold technology.

Key takeaways:

- Examine Three Common Molding Processes

- Learn how Material Selection Impacts an Application’s Performance

- Discuss Design Features that Influence Product Development

Gain an understanding of multicomponent LSR molding and the importance of involving silicone component manufacturers early in the development process to aid in selecting the right design.

Key takeaways:

- Learn how multicomponent LSR technology can simplify application design and the assembly process

- Understand potential design challenges and how they can be averted using multicomponent molding

- Examine different methods of combining materials with injection molding

Polymer & Sealing Technology

Key takeaways:

- Find out where to specify Forsheda® V-Ring to lower friction and reduce downtime

- Understand the design features that work together to make a better seal and their benefits to you

- See testing data related to wear and environmental conditions that prove its performance

Key takeaways:

- Learn about our comprehensive portfolio of flat gaskets and how these can boost application performance, reduce downtime and simplify maintenance processes

- Understand how we collaborate with customers to specify materials and develop designs to meet your unique flat sealing needs

- Find out about our package of tools to support customers with product specification, including the FlatSeal™ Selector and our FlatSeal™ Guides

Key takeaways:

- Understand Trelleborg’s innovative automated fiber placement bearing manufacturing process

- Discover the key benefits of these bearings, including high strength and durability with reduced weight and friction

- Learn about applications with case studies where HiMod® Advanced Composite Bearings are in use today

Find out about the unique iCast™ digital manufacturing process, an innovation in liquid silicone rubber (LSR) processing that is a cost-effective way to develop product variations or try out different design concepts.

Key takeaways:

- Gain an understanding of how iCast™ technology meets demand for low volumes to minimize the transition time from design to manufacturing

- See how digitalization and innovative manufacturing technologies are used to reduce the lead time for LSR products

- Learn how the parts produced compare to standard injection molded parts

Understand how working with Trelleborg Sealing Solutions as a development partner leads to customized high-performance polymer solutions that solve your engineering challenges.

Key takeaways:

- How thermoplastic products can solve your engineering challenges

- Where our solutions can consolidate multiple parts, reduce weight, or improve strength

- Why thermoplastic materials offer advantages over more traditional materials

Learn about the manufacturing processes and benefits of multicomponent products at Trelleborg Sealing Solutions, including material combinations from engineered plastic, elastomer and Liquid Silicone Rubber (LSR).

Key takeaways:

- Explore the manufacturing technology behind multicomponent solutions and their key benefits

- Find out which material combinations are possible

- Discover our development center capabilities

Understand how thermoplastic composites are specified within the Automotive, Oil & Gas and Industrial markets, delivering quality and efficiency in a wide range of materials and designs.

Key takeaways:

- Review thermoplastic composite manufacturing, including in-situ consolidation via automated fiber placement (AFP)

- Discover the importance of thermoplastic composite use in e-mobility and downhole Oil & Gas applications

- Learn the commercial uses of advanced composite bearings

Semiconductor

Explore how Trelleborg’s advanced simulation capabilities can significantly accelerate your design and qualification times and reduce your costs for semiconductor applications.

Key takeaways:

- Discover how our unique compression set analysis based on real-life data fed into finite element analysis (FEA) tools provides you with more accurate seal

- Find out how FEA-based simulation can be applied to analyze and predict other seal attributes, including viscoelasticity, abrasive wear and thermal effects

- Learn how you can benefit from FEA-based analysis to inform material and design choices for bespoke processes and applications

Discover the range of advanced manufacturing capabilities for Isolast®, Trelleborg’s proprietary portfolio of high-performance perfluoroelastomer materials that withstand extreme temperatures and harsh media.

Key takeaways:

- Learn about our innovative FFKM sealing solutions, beyond standard O-Rings

- Find out about our wide range of products – from tiny microseals to giant Fleximold™ parts

- Understand how we combine material, manufacturing and engineering capabilities to solve your most challenging applications

Understand how Finite Element Analysis (FEA) simulations can help when choosing the right material for semiconductor applications and how it can aid in predicting product lifetime.

Key takeaways:

- Why choosing the right elastomer sealing material is crucial to maintain vacuum integrity in semiconductor processes therefore keeping tool downtime to a minimum

- Explore our new polymer material range for semiconductor applications and their properties

- Discover specific Finite Elemental Analysis (FEA) capabilities to predict the lifetime of the sealing parts

Find out about the Isolast® K-Fab flange seal and how it gives long-term sealing and increased productivity in today’s most extreme Subfab conditions, lowering the overall cost of manufacturing of microchips.

Key takeaways:

- Learn about the unique puzzle-shaped connection between the flange insert and elastomer element, making assembly of the flange easier

- Find out how the Isolast® K-Fab flange seal contributes to significantly lowering the overall cost of manufacture of microchips

- Hear about our range of solutions engineered for your critical Subfab applications

Key takeaways:

- Learn about the features and benefits of the Isolast® PureFabTM material range, and the characteristics of the different materials

- Discover how these materials save time and costs for semiconductor manufacturers

- Understand how Isolast® PureFabTM materials extend seal life and prevent contamination, even in the most demanding semiconductor processes

- Find out about the intensive testing process undertaken to prove the performance of these materials, including plasma erosion tests in the most common process gases, long-term mechanical tests, and purity tests including trace metal analysis and outgassing

Understand the features and benefits of four best-in-class materials in the Isolast® PureFab™ range, specifically engineered to increase product yields and decrease process defects for critical semiconductor sealing applications.

Key takeaways:

- Learn about the market-leading features and benefits of the new Isolast® PureFab™ material range, and the intensive testing processes used to prove the materials performance

- Determine how extensive competitor benchmarking helps identify the best offering and reduces risk when qualifying new materials in highly sensitive environments

- Discover how this material saves time and costs for semiconductor manufacturers by extending seal life and preventing contamination