Trelleborg Showcases Medical Device Component Innovations at Medical Technology UK

Specialist Multicomponent Technology

Attendees can learn about specialist multicomponent technology that enables production of components that cannot be produced by any other method, pushing the limits of manufacturing innovation. The technology benefits medical equipment manufacturers by helping them meet their design goals, such as making products smaller, lighter, and more compact, increasing robustness, and improving inherent quality, while lowering total cost of ownership.

Referred to as 2K, 2-shot, multi-component injection molding or co-injection, Liquid Silicon Rubber (LSR) experts employ highly sophisticated tools and process engineering to develop novel solutions, combining two, three or more individual materials and components into one fully bonded, robust component. Parts are more hygienic, eradicating the dead space where bacteria can breed, and lower costs by cutting out assembly as well as reducing the number of components in the customer’s supply chain.

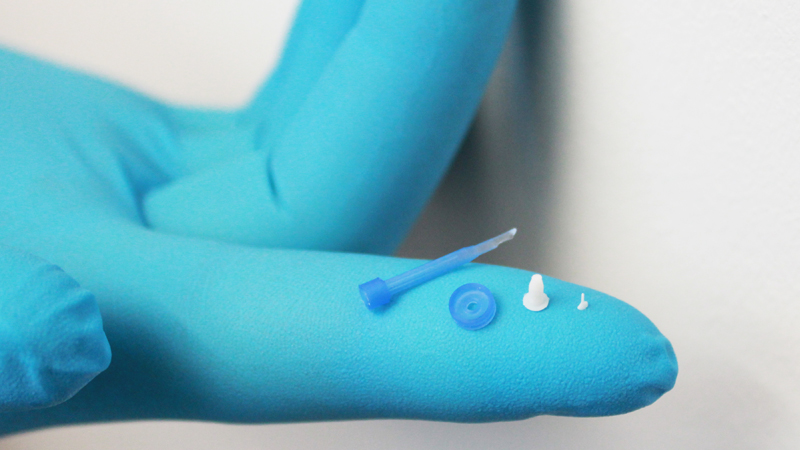

Micro molding for Device Miniaturization

Related to this technology is micro molding, critical to facilitate the miniaturization of devices to make them wearable and implantable. Production of components below 10 milligrams in weight is possible through needlepoint injection technology and fully automated parts handling. All micro molded parts are virtually flash-free and do not require secondary deflashing thanks to Trelleborg’s high dimensional flashless and wasteless design principles.

Tony Fagg, Key Account Manager at Trelleborg Sealing Solutions, says: “As medical devices become ever more sophisticated and smaller in size, the challenge for the component manufacturer is how to fit multiple functions into a limited space. Multicomponent LSR technology and micro molding offers a solution to this.

“Multicomponent molding can extend design options as no other technology can do, giving medical device developers the opportunity to go beyond function. As product profiles are virtually boundless, medical device designers have options that they may not even be aware of being possible.”

Trelleborg Healthcare & Medical is a leading exponent of moldings often used in implantable healthcare and medical devices. Utilizing in-house precision tooling and expertise, Trelleborg creates custom silicone and thermoplastic molded parts with tight tolerances, while satisfying the need for rapid product development with quick turnaround prototypes.

Attendees will be able to explore Trelleborg’s advancements in multicomponent and micro molding capabilities.

In addition to multicomponent and micro molded parts, Trelleborg will display Isolast® perfluoroelastomer (FFKM) sealing solutions, specialty extruded tubing and hose products, drug delivery devices, and Seal-Glide® nanoscale surface treatment at Medical Technology UK.

Learn more

>>Find out more about solutions for Healthcare & Medical

>>Get in touch to discuss Multicomponent technology for your project