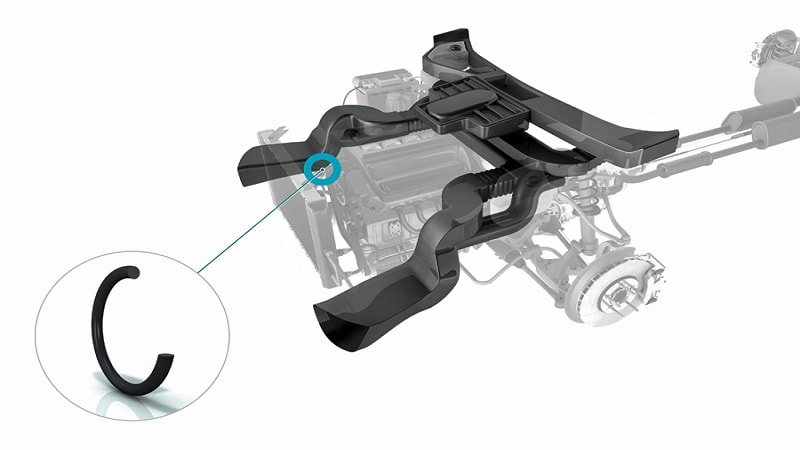

Sealing solutions to meet the ever-changing demands of automotive applications

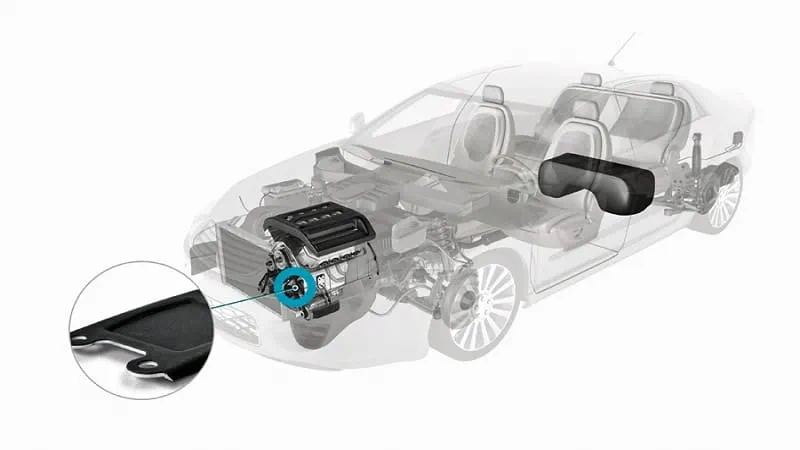

Air Conditioning

A car’s air conditioning system is complex, with a multitude of O-Ring's running throughout the pressure lines to and from a belt-driven/electric compressor. Every connection point needs to be sealed in order to ensure optimum performance.

Requirements for sealing air conditioning systems

- Operate under relatively high pressure

- Fit into small installation spaces

- Minimize wear to maximize seal life

- Fulfills environmental legislation for zero leakage requirements

Sealing Solution

Custom-designed engineered molded components can incorporate multiple parts into a single product, allowing placement into the limited space available in air conditioning systems. Materials engineered to prevent stick-slip, extend seal and system life where air conditioning use is limited.

Trelleborg Products

O-Ring, special PTFE rotary seals

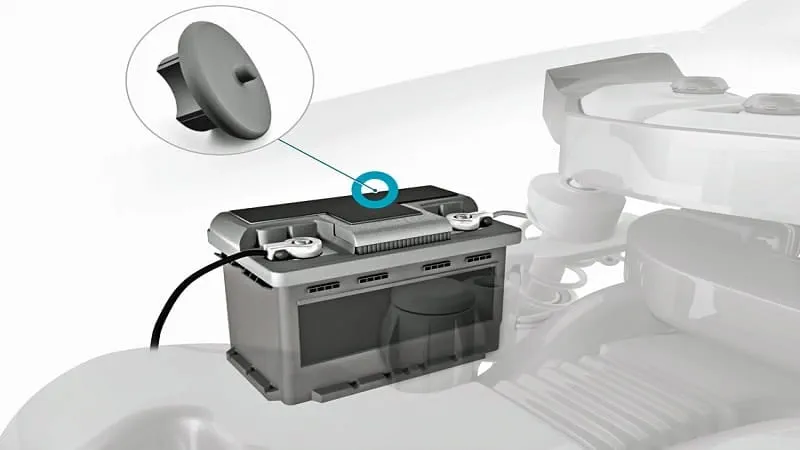

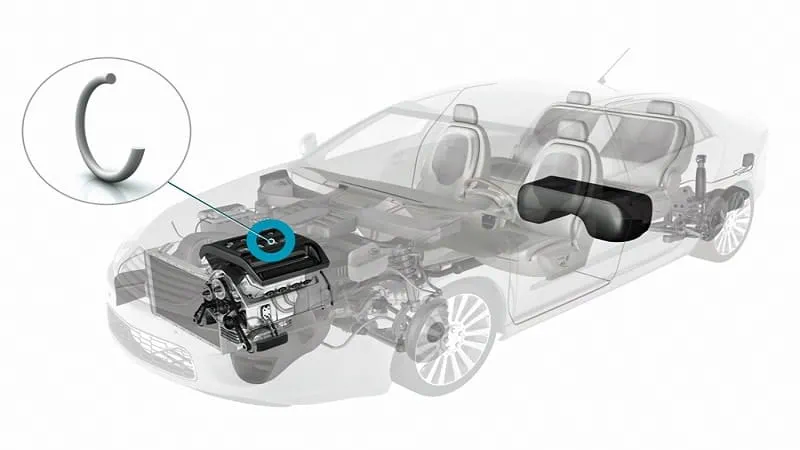

Battery

The battery provides the power to a number of critical systems in the car and without it, the vehicle is inoperable. Start-stop options as well as hybrid powertrains to minimize emissions, have challenging impacts on new battery technologies. Drivers expect to start their car whatever the weather, first time, every time. For that kind of operational dependability, reliable sealing and battery venting is needed.

Requirements for sealing batteries

- Outstanding reliability

- Extended seal life

- Operation in temperature extremes

Sealing Solution

Ventseal is specially designed for locked container applications such as batteries. It combines a seal and pressure relief function all in one product.

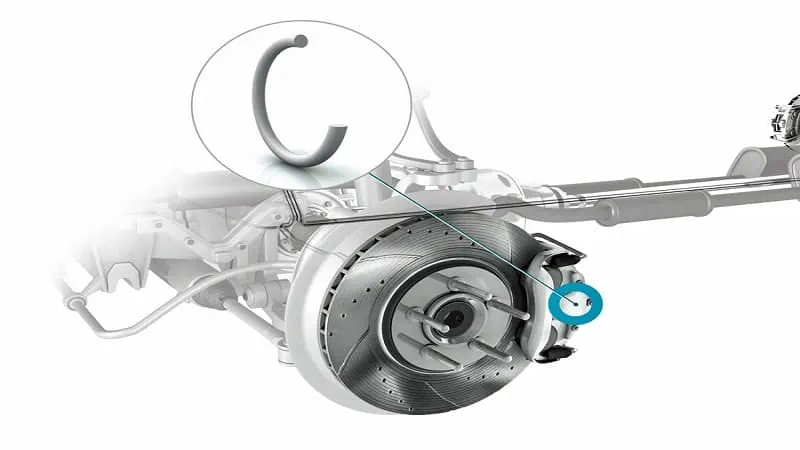

Brakes

Probably the most safety critical of all automotive applications , it is vital that when needed the brakes will activate instantaneously.

Requirements for sealing brakes

- Consistent quality over high volumes

- Media resistant to brake fluids

Sealing Solution

The quality of braking components are ensured with materials specially compounded on mixing lines dedicated to brakes.

Trelleborg Products

O-Rings, Custom-molded components

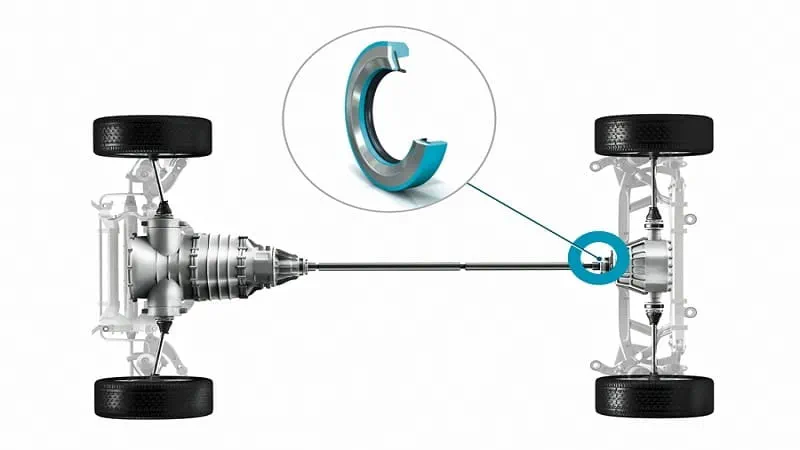

Drivetrain & Transmission

The drivetrain and transmission of a vehicle adapts the output of an engine to the drive wheels. Engines operate at relatively high rotational speeds and the transmission reduces that speed to the slower wheel speed, increasing torque in the process.

Requirements for Sealing of Transmission

- Advanced rotary sealing solutions\

- Low friction to optimize the transmissions operation

- Outstanding wear resistance to extend transmission life

- Resistance to the lubricants within the transmission

Sealing Solution

Complex sealing configurations combine a number of advanced seals that seal in lubricants, prevent ingress of external media and provide maximum performance in rotary applications due to unrivaled low friction.

Trelleborg Products

Turcon® Roto L, Slyd Ring®, Back up Rings, O-Rings, Quad-Rings ®, Rubore® seals

Electronic Control Unit (ECU)

Sophisticated electronics that control key functions of the car are housed in the metal/plastic box of an ECU. Often situated in the engine compartment or other areas subject to environmental conditions, good sealing is vital as failure is not an option.

Requirements for Sealing of ECUs

- Effective sealing of casings to reliably exclude any media that may affect sensitive electronics

- Materials must stand up to the harsh conditions of the engine including temperature extremes and salt spray from the road

- Low media permeation (e.g. from transmission oil)

Sealing Solution

The Rubore® Cover Seal integrates the seal and ECU cover into one single unit, thereby eliminating costly manual installation. This results in a perfect solution at a reduced cost.

In addition, integrating the ECU cover and the seal, as seen with the Rubore® Cover Seal, reduces the number of parts therefore minimizing logistics, assembly and administration costs. Full elastomer gaskets are also available for a wide variety of applications. In-house testing of permeation is available.

Trelleborg Products

Engineered Molded Components, Rubore® Seals, O-Rings

Fuel Systems

Running at extreme temperatures and high pressures, secure and reliable sealing is required throughout the fuelling system – in the fuel injectors, the common rail system, the fuel lines and fuel tank.

Requirements for sealing the fuel system

- Operate in a wide temperature range, very low to very high

- High pressure performance

- Optimized performance for efficient engine operation

Sealing Solution

A wide range of seals are available for the different sealing environments within the fuel system. They are composed of specialized materials that have been engineered to withstand gasoline, diesel and bio-fuels, as well as temperature and pressure extremes.

Trelleborg Products

O-Rings, Engineered Molded Components, PTFE-based square cut rings, reinforced Diaphragms

Special low temperature material

Trelleborg Sealing Solutions has developed a fluoroelastomer sealing compound for fuel injection applications that performs at extremely low temperatures.

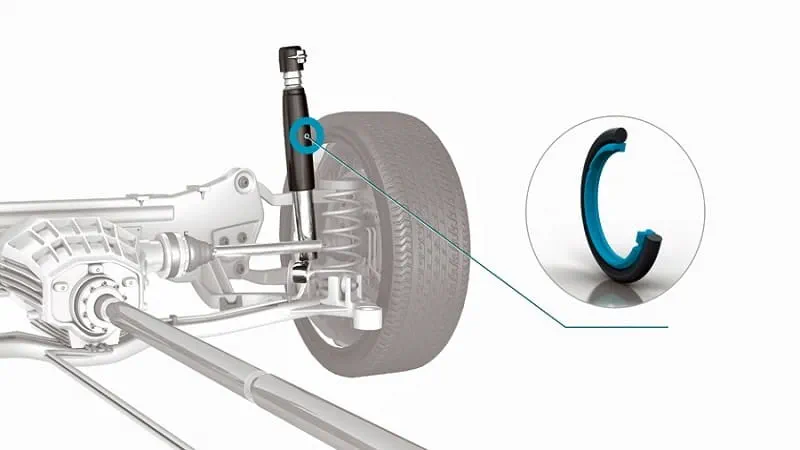

Ride Control

The objective of ride control systems is to combine steering stability with good handling characteristics while maximizing passenger comfort. The ride control system incorporates the suspension system and shock absorbers.

Requirements for sealing ride control

- Low friction avoiding stick-slip

- Wear resistant

- Chemical resistant

Trelleborg Products

- Twin Seal : Very low friction rod seal

- O-Rings : Low temperature flexibility

- Buffer Rings : Avoids metal-to-metal contact

- Back up Rings : Supports O-Rings in high pressure situations

- Vane Seal: Specialty sealing

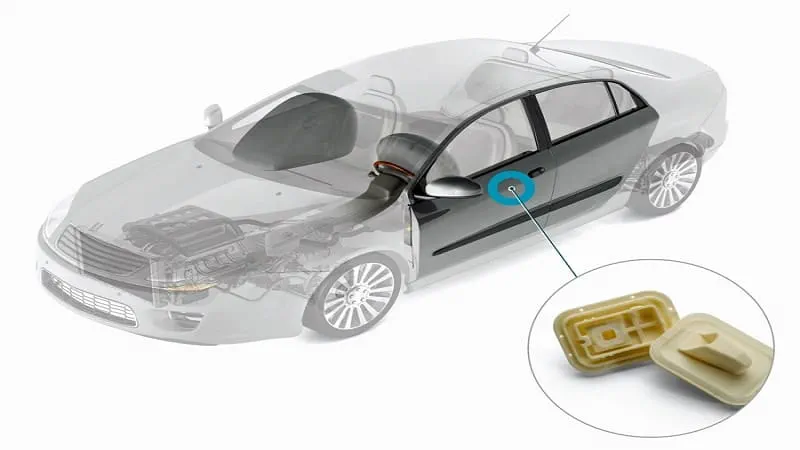

Safety Systems

Today's cars include a wide range of safety solutions to protect drivers and passengers from various types of collisions. This includes airbags installed to surround the front and rear seats.

Requirements for sealing airbags

- Absolute quality throughout production over very high volumes

- Small seals with tiny flashfree holes

Sealing Solution

Trelleborg Sealing Solutions uses its capabilities in liquid silicone rubber injection molding technology to produce safety critical components, completely flash-less, in a clean and fully automated process.

Trelleborg Product

Sensor Cover

Thermal Management

Engines operate at high temperatures and to maximize life of certain engine components, the engine needs to be cooled using fluid that flows through the radiator.

Requirements for sealing engine cooling systems

- Operate in combination with high rotational speeds and high pressure

- Reliable low-friction sealing to reduce CO2 and save fuel

- Withstand coolants and lubricants and operate in poor lubrication conditions

Sealing Solution

Specialized seals manufactured using the Rubore® Seal technology or standard full elastomer gaskets, provide custom-made solutions with an extended seal life.

Trelleborg Products

Rubore® Seals, Gaskets, O-Rings