Trelleborg DrainPacker System comes to rescue

Through our distributor SECA, installation contractor Pipe Spy and certified engineer CSDEE Engineering, Trelleborg DrainPacker System comes to the rescue to repair a DN525 FRC stormwater pipe with protruding PVC rainwater connections.

Challenge:

During an off-maintenance CCTV inspection, penetrations were identified from an adjacent new residential property directly in the obvert of the pipe. The extent of the penetration was approximately 1/3 of the pipe diameter, hence in this case these penetrations were approximately 150 millimeters into the stormwater pipe. Obstacles protruding into a pipe can have several implications during a heavy rainstorm such as the following:

- Increased risk of flooding and damage: When rainwater flows through the pipe, these obstacles can obstruct the flow, causing water to back up and potentially flood the surrounding area. This can lead to property damage and erosion.

-

Pipe blockage and clogging: Debris, leaves, and other materials can accumulate around the obstacles, leading to partial or complete blockage of the pipe. This reduces the pipe’s capacity and may cause backups.

-

Erosion and undermining: Water flowing around obstacles can erode the soil around the pipe, potentially undermining its stability. This can weaken the pipe’s foundation and increase the risk of collapse.

Our activities:

Upon identifying the protruding connections, Pipe Spy was asked to recommend a fast solution to remove the two DN100 protruding PVC connections and upon detailed inspection of the workmanship on installed connections, it was clear that FRC pipe structural integrity was compromised and structural repair was required.

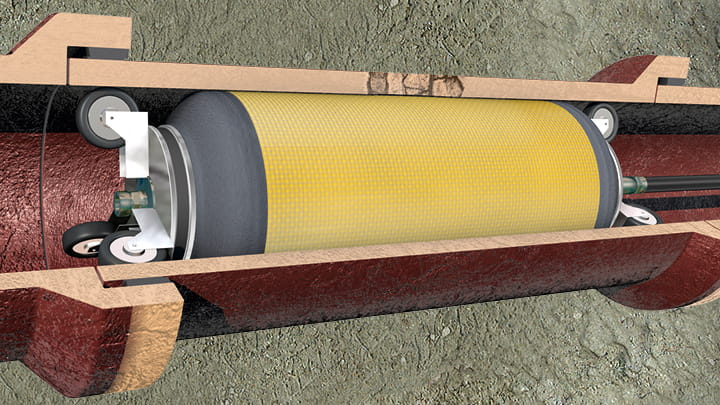

Pipe Spy installed 2 overlapping Trelleborg DrainPacker patch repair liners of 3 layer 1400gsm with 6 millimeter thickness and 600 millimeter repair length to reinstate the structural integrity of the FRC pipe and reopened the rainwater connections.

After months of planning, preparation and comprehensive training, the repair works were executed successfully. The rehabilitation of the pipes took less than three hours, including a curing time of one hour. The liner fit the original pipe seamlessly. The walls of the pipe were clean and water flowed through smoothly without affecting the speed. The renovated pipes now have a service life of 100 years as required by Council for the FRC pipes.

Solution details: Trelleborg DrainPacker

For more information contact: