Engineered Composite Structures

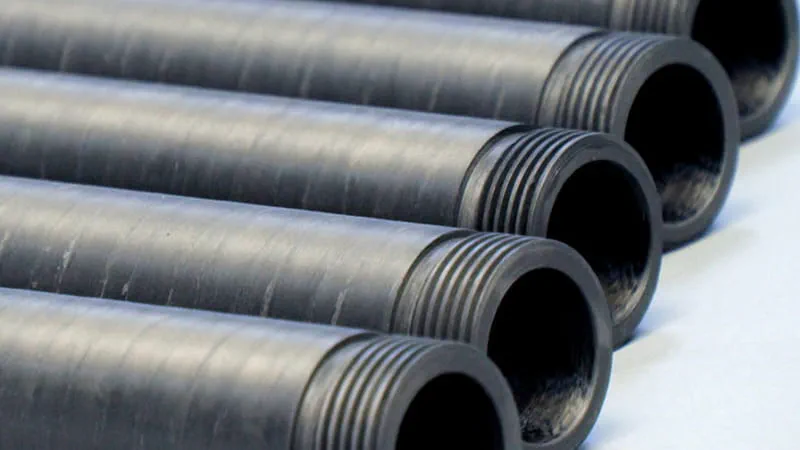

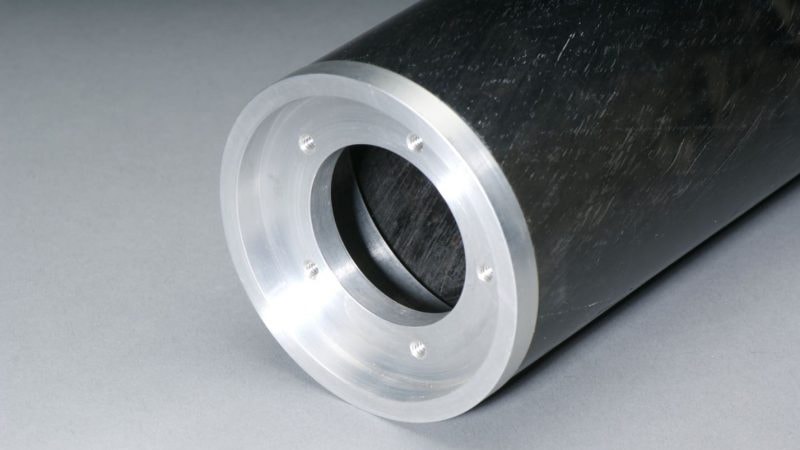

Trelleborg Sealing Solutions has a 30+ year record of engineering composite structures unique to each client. These structures are frequently sought out when solutions are needed to replace metal, reduce weight, isolate electronics, or offer high-level corrosion resistance. Using additive manufacturing methods and a varied group of materials makes the design options virtually unlimited. Working with continuous-fiber composites, we are able to engineer and manufacture parts offering performance unequaled by metals or conventionally molded components.

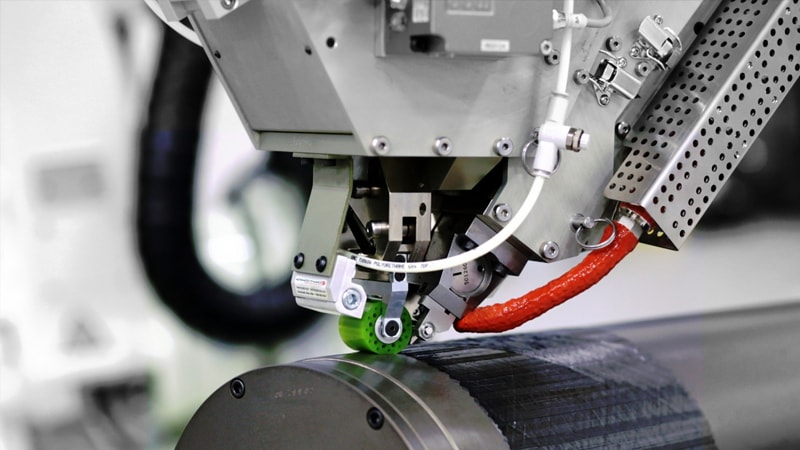

Different manufacturing processes are ideally suited for different part geometries. At Trelleborg Sealing Solutions, we make use of fiber placement, compression molding, autoclave, and hand lay-up. Our expertise lies in our extensive understanding of advanced fiber placement technologies. With thermoset fiber placement, our core competency lies in small complex part geometries. When it comes to thermoplastic fiber placement, we excel with the use of our in-situ process.

Advanced thermoplastic fiber placement is our proprietary, patented technology which uses unidirectional prepreg material (continuous fiber reinforcement in thermoplastic resin matrix) with high heat and pressure to consolidate the structure ‘on the fly’ (in-situ) or as it is manufactured. There is no post-processing (autoclave or oven cure) which allows for greatly reduced residual stresses.

This technology allows us to orient the reinforcing fibers from 0 degree (axial) to 90 degrees (hoop) and anywhere in between. The result is a well-consolidated structure with continuous fibers placed in the directions that they are needed for optimum strength and stiffness for a high-quality, high-performance part. Our robotic in-situ process provides the repeatability and accuracy you need for high-quality, serial production.

Many structures in our photo gallery represent our fiber placement technology capabilities in both size and shape. We have also included a video gallery to help demonstrate the benefits of in-situ fiber placement. And lastly, there is a wealth of technical support at Trelleborg Sealing Solutions, which is evident in the technical papers that are available for your review.