Pipe material when designing corrugated pipe joints

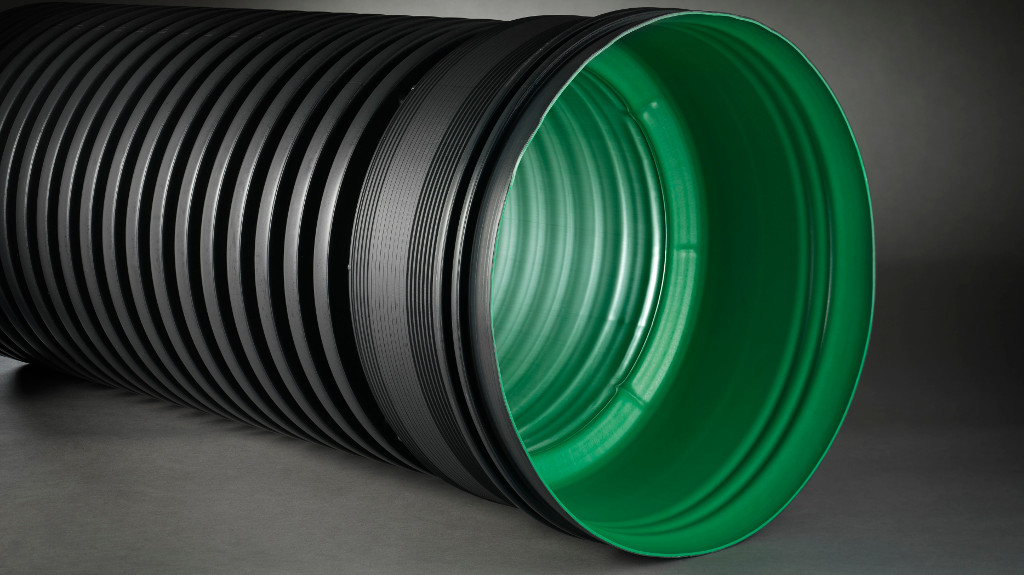

When designing seals and joints for PVC-U pipes, in the majority of cases the housing of the joint can be taken as a ridged body with little or no flex or deformation resulting from the force applied by the rubber seal. However with Polyethylene and Polypropylene joints, especially when the pipe is corrugated and, or of a structured wall nature, it is necessary to consider potential socket expansion both during and after jointing and also determine where the strength of the corrugation is sufficient to withstand the forces from the seal.

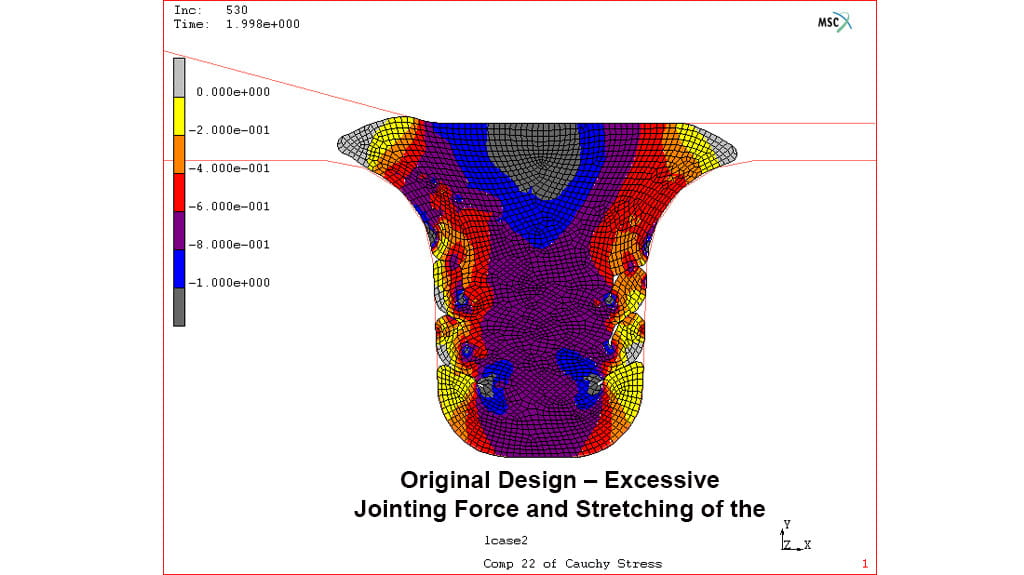

There are existing applications where the design of the joint and seal has been based on the ‘fill the groove full of rubber’ principle.

This results in excessive jointing forces, often the socket will have to expand to accommodate the seal and in extreme cases of joint tolerance the corrugations may be deformed or may even collapse.

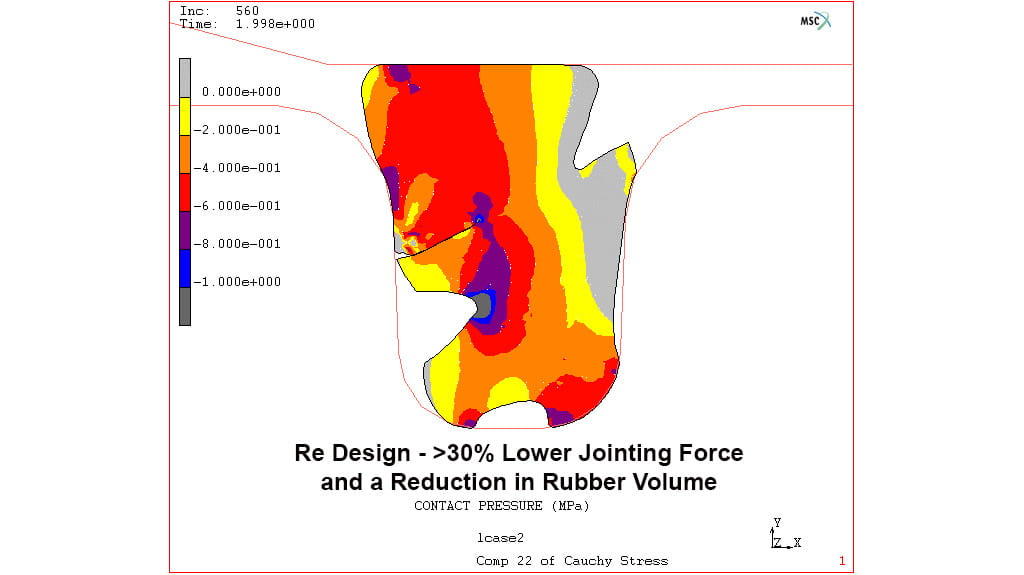

These images below show a real example of how a joint, originally designed with excessive rubber volume, may be re designed with the aid of Finite Element Analysis resulting in >30% lower jointing force and a significant reduction in rubber volume.

In summary, it’s not always ‘how much’ but where you put it that’s important.