Trelleborg in collaboration with SSAB on fossil-free steel

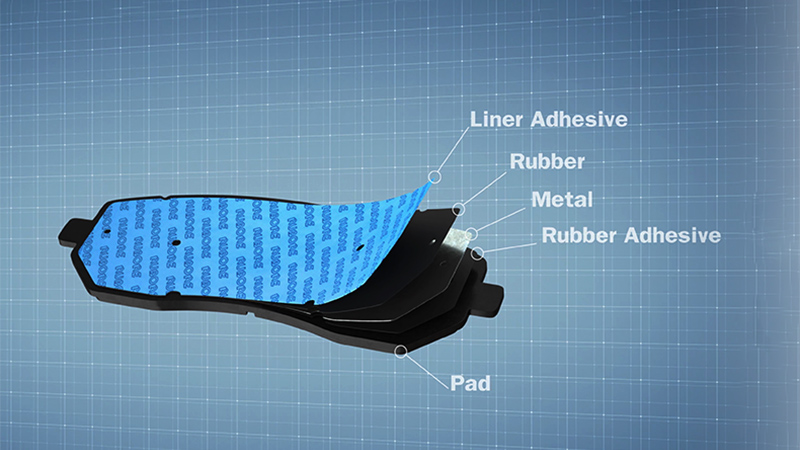

Vehicle manufacturers are in high demand for sustainable components. This is especially true in the growing electric car segment, where the car's materials account for a large part of the remaining carbon dioxide emissions after the exhaust gases have been eliminated. Eliminating braking noise is even more important for quiet electric cars, as disturbing sounds are perceived more clearly.

Therefore, as a global leader in sound-damping shims, Trelleborg wants to offer brake shims with a significantly lower carbon footprint than the standard. This agreement with SSAB on future deliveries of fossil-free steel is an important part of that transition.

“Our unique solutions to eliminate vibration and noise in cars are based on our technical knowledge and experience. With fossil-free steel in our components, we will take a leap forward and strengthen our market-leading position,” says Stefan Lundström, Business Unit President, Trelleborg Sealing Solutions Kalmar AB.

"We are happy to welcome Trelleborg Sealing Solutions as a fossil-free partner. Together, we will support the automotive industry in delivering the key parts that both producers and consumers are demanding. In the end, it will deliver more sustainable cars to the customers,” says Olavi Huhtala, Head of SSAB Europe.

Traditional steel production represents a significant source of CO2 emissions. By changing the way steel is produced, SSAB wants to cut emissions and create a fossil-free value chain with customers and partners.