A watertight future: Trenchless pipe rehabilitation in the Asia-Pacific

At Trelleborg, we understand how important quality and precision are when it comes to infrastructure. Based on cured-in-place pipe (CIPP) lining technology, our pipe rehabilitation solutions solve the issues in the complex water networks of the markets we serve, including the Asia-Pacific region.

Asia-Pacific (APAC) is the world’s biggest and most diverse water infrastructure market. A common problem throughout the region is aging infrastructure and increasing water leakage. This is particularly pronounced in New Zealand and Australia, where much of the infrastructure dates back to the later 20th century and is reaching the end of its 50-year life. Meanwhile, growing populations and climate change are adding to an increasingly challenging situation.

Water loss: An unsustainable issue

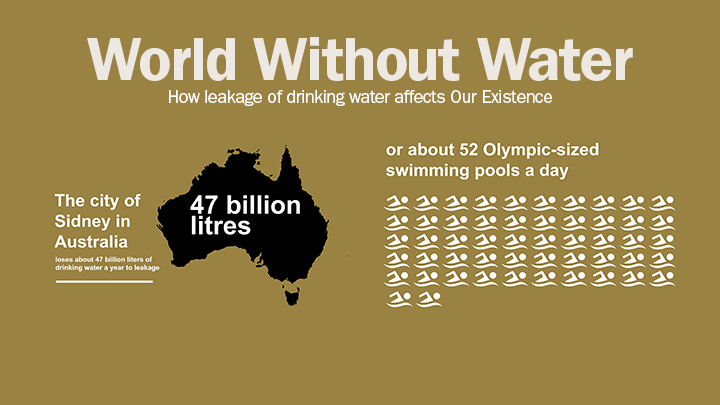

For example, the city of Sydney loses about 47 billion liters of drinking water a year to leakage[1] – about 52 Olympic-sized swimming pools a day – and is experiencing a sharp growth in the number of “high-priority” leaks. In Australia’s largest city, the primary supply of drinking water is from surface water. With periods of prolonged drought increasingly common, municipal water supplies are put under extreme pressure, creating the need for more sustainable water cycles.

In New Zealand, estimates are that more than one-half of Wellington’s pipes need replacing at a cost expected to run to about $NZ600 million over the next decade[2]. Even the Prime Minister suffered, with one high-profile leak near her official residence lasting at least six months.

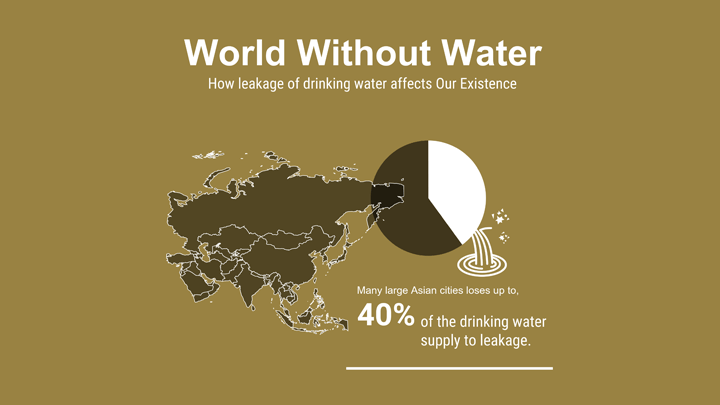

Not limited to the Pacific region, elsewhere in APAC, many larger Asian cities lose up to 40% of their drinking water supply to leakage, compared with 20% in many cities in Europe and the United States[3]. Water loss happens for several reasons, including the complexity and quality of pipe installations, and is becoming a growing – and expensive – issue for local water authorities and asset owners alike.

When a drinking water pipe leaks, the escaped water often finds a path underground, where it is wasted in a process known as exfiltration. However, as well as the loss of valuable drinking water, the pipe can also be contaminated by the infiltration of pollutants from the soil, for example those originating from overfertilization or defective or incorrectly laid drainage pipes.A defective pipe is basically susceptible to root ingrowth, backfill, and even breakage. Continuous water leakage washes out the surrounding soil and can ultimately lead to the failure of the drainage pipe and the collapse of roads.

Pipe rehabilitation: The right solution, if done right

The fact that traditional “trench-based” repair methods are becoming less feasible in busy urban centers with increasingly complex underground infrastructures, compounds these issues.

“Think about what’s beneath a typical city street,” says William Wong, APAC Business Development Manager for Trelleborg’s seals and profiles operation. “You have gas mains, electricity, sewage pipes, and probably even fiber optic cables intersecting with each other, and the more populated a city is, the more underground infrastructure is required. That’s not to mention everything you see at ground level: in most cities, there’s physically no room to lay new pipes inside a repair trench.”

It is also a question of time: blocking off a street and digging up a single water pipe can take months, causing major disruption to businesses and residents. Increasingly, the solution lies in non-invasive, trenchless rehabilitation solutions. However, this rehabilitation is still contingent on two factors. First, the rehabilitation itself must be more efficient in terms of time and costs, and less disruptive and polluting than the trench-based method. Second, the repairs need to stand the test of time; rehabilitation becomes a false economy if repairs are performed more often.

Trelleborg solutions for trenchless pipe rehabilitation are efficient, environmentally friendly, and sustainable. “With a trenchless pipe repair, repair work is usually completed in one night,” says Wong. “You can now repair a typical pipeline in about eight hours depending on the site situation. In fact, for less extensive damage, it only takes a couple of hours. It’s also much less disruptive; picture a surgeon performing keyhole surgery rather than cutting the patient open.”

These watertight trenchless solutions bypass the need to dig and the costly upheavals and disruptions that make traditional installations so difficult. Furthermore, they are simpler to install as well, reducing the risk of leakage due to installation errors.

Solutions for the APAC region

For ease of application, Trelleborg offers targeted solutions for the task at hand. “It depends on the pipe and its application,” Wong explains. “The material you choose will differ based on whether you’re dealing with a water main or a drainage pipe, and factors such as the service pressure or alignment of a pipe must be considered. Depending on the application, the materials have to meet certain criteria to achieve a perfect rehabilitation result. But this is one of Trelleborg's main strengths: we have customized solutions for virtually any challenge in pipe laying and rehabilitation.”

In the rehabilitation of sewer pipes, for example, our flexible pipe liners are used in combination with our polymer resin systems. They can be used to repair long, complex house connection lines and building pipes, even with bends or expansions, and stabilize them for a further 50-70 years.

In the event of a small, local leak, there is a simple solution to repair it using a resin-impregnated fiberglass mat, thus providing a quick remedy.

Solutions are also available for pressure pipes, including mechanical sealing options for partial damage. Meanwhile, research is currently being carried out into solutions that, as with sewage pipes, can rehabilitate long pipe runs with special glass-fiber-reinforced hose liners.

Expertise in polymer development

As mentioned, one of Trelleborg’s biggest advantages is its expertise in polymer development and innovation. This is because of Trelleborg Group’s cross-company approach to innovation, in which engineers and innovation experts work closely with the sales teams and customers to develop the right solution for specific problems.

The sustainability dimension

Given the APAC region’s ongoing challenges with water, investing in high-quality maintenance of pipes is an easy way to yield significant water savings. Trelleborg’s rehabilitation solutions, engineered to remain watertight for at least 50 years, can last even longer when applied correctly, meaning asset owners can enjoy peace of mind when looking for a sustainable solution. The result is high-quality infrastructure that not only saves water, but also labor and costs.

The exciting thing about Trelleborg’s APAC solutions is that there are many options to meet the wide variety of needs in a diverse marketplace, while also leading the way in sustainability. This is particularly promising in the Pacific region, where the need for more efficient, eco-friendly infrastructure has never been more pressing. Despite the region’s many challenges, the future looks bright.

Trelleborg’s pipe rehabilitation provides local authorities, water authorities, property owners, and asset owners around the world with watertight solutions that last. We use the most efficient, eco-friendly technology for servicing and maintaining water infrastructure, particularly when it comes to property drainage pipes. For more information, contact William Wong.

[1] https://www.smh.com.au/environment/conservation/sydney-springs-leaks-response-nsw-water-20181208-p50l11.html

[2] https://www.letstalk.wellington.govt.nz/three-waters-network

[3] https://www.adb.org/sites/default/files/publication/27473/reducing-nonrevenue-water.pdf