State of the art sealing systems for concrete pipelines

The role seals can play in maximizing concrete pipeline performance.

Julian West, Product Manager Pipe Seals, looks at developments in concrete pipeline performance and the role pipe seals can play in maximizing this.

Concrete pipes have been used for water and wastewater applications for many decades, in fact their origins can be traced back to Roman times. More recently, as the trend towards urbanization continues unabated, so too does the need to provide subterranean infrastructure to meet the sanitation needs of so-called mega cities. Coupled with the continuing growth of the world’s population, this has meant an increasing need to connect ever more remote places and, consequently, lay pipeline in more extreme environments.

This brings its own set of challenges, both in terms of installation and accessibility in the immediate term, and of material performance and durability of pipeline infrastructure in the longer term. Correct jointing of concrete pipelines will have a significant impact on the long-term service of the pipeline itself. Avoiding leakage and removing the need to repair are key drivers. It is therefore important that full and proper consideration is given to understanding developments in sealing and jointing design and manufacture in order to specify correctly and to ensure that maximum pipeline performance is built-in from the outset.

An overview of pipe developments

Originally, pipes were made using centrifugal spinning techniques, where a cylindrical mold would be spun on rollers and the concrete fed inside. The centrifugal forces would distribute the concrete around the inside of the mold to form the pipe. However, using this method, production was slow and it was difficult to control the strength of the concrete.

The big change came when vertical casting was introduced. This system uses an outer mold with an inner core and semi-dry concrete is fed round the annulus between the two. Vibration is applied to get the desired level of compaction. Using this method, the pipe can be demolded immediately and mold equipment can be recycled for the next pipe. Naturally, this makes the process much faster and more cost effective.

Concrete remains to this day a popular material for pipe construction despite innovations in new materials such as plastics. One of its main advantages is its rigidity and load-bearing capability. The rigid nature of a concrete pipe means that when in the ground, it forms a structure by itself and is therefore able to withstand heavy loads from both earth and additional traffic. This also means that concrete can be more relaxed in installation despite its rigidity! However it is still important that the method of installation and the calculations to work out the specific requirements for concrete durability are carried out thoroughly to ensure maximum pipeline performance.

While the manufacturing process of pipes has developed significantly, it is the design of the joint that has perhaps seen the biggest changes. Until the 1960s, most water and sewerage pipe joints were rigid and made from horse hair, tarred rope and cement mortar. Being totally rigid, the joints had no flexibility to allow for ground movement. It was the introduction of flexible joints based around rubber rings during this decade that was the turning point in increasing joint efficiency. These flexible rubber joints meant that for the first time natural movement could occur between pipes, effectively allowing one pipe to move against another without causing any damage or breaking.

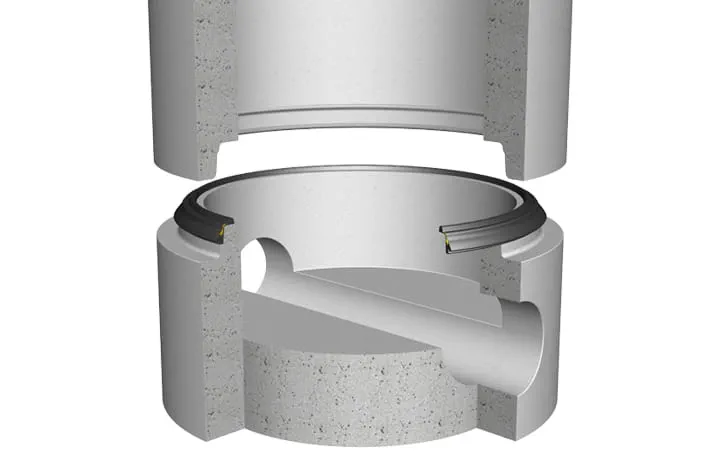

Seal technology has continued to develop ever since, with the advent of integrated seals boosting performance further. Nowadays, the ability to integrate flexible rubber seals within a concrete pipe socket during manufacture is raising standards of leak tightness from infiltration and exfiltration even further. Integrating seals into the pipeline at the point of manufacture effectively reduces the likelihood of human error and its negative impact on the performance of the pipeline. By ensuring the seal is manufactured into the concrete pipes themselves, a contractor can be certain the correct seal is in place in the pipe and that the seal will not go missing or be damaged in transit, or be incorrectly installed in the trench due to errors on-site.

The modern-day ease and reliability of integrated jointing significantly enhances seal durability and consequently long term pipeline performance. Integrated seals are anchored in and simply won’t move, and while this means that correct alignment needs to occur during the manufacturing process, this is a controlled environment and one where the margin for error should be far lower than on a construction site. Then once on site, centering the joint becomes easier as there is a rubber buffer to push up against, or to center up to, prior to pushing the pipes together. Introducing the pipes, lining them up and only then jointing them is also a more straightforward laying process and one which significantly reduces the margin for error due to poor installation.

Also key to achieving long term pipeline performance is air testing the installed pipes prior to filling the trench. This is a crucial step and ensures that any issues are identified at a point when they can be easily rectified. By blocking two ends of the pipeline and pressurizing the inside of the pipe it is possible to check for leakage and ensure a proper seal has been created, only once this has been correctly established should back filling occur.

Partnership in pipe design

There is now an abundance of application specific seals which, if used correctly, can continuously optimize pipe infrastructure performance. Pipe manufacturers who fully utilize the partnership with their seal manufacturer, will gain from the expertise and valuable technical advice and support they have to offer. This should include training on how to use the seals, specifically how to joint them and how they function, as well as a strong knowledge of water infrastructure requirements across the globe, including relevant legislation.

A seal manufacturer should provide the necessary expertise to design-in features that can overcome project-specific challenges. For example, optimizing jointing forces at low temperatures, to create zero push-back during installation in even the coldest conditions is now possible. An expert understanding of rubber’s behavior is imperative if the seal is to perform exactly as required over its life.

The impact of material choice

The type of rubber used for pipe seals should be comprehensively considered, as the right choice will aid in extending the life of the asset and infrastructure as a whole. This can sometimes be overlooked.

Seals are primarily available in two types of rubber – styrene-butadiene rubber (SBR) and ethylene propylene diene monomer rubber (EPDM). The former has traditionally always been used in pipe seal manufacturing, but in some cases EPDM can offer additional benefits. It is ozone resistant, offers long term stress relaxation performance - maintaining its elastic properties for longer – and ensures optimized rubber stability and durability. EPDM is ideal for integrated systems.

Challenges of production and installation

The production of an integrated seal within a concrete pipe must be carefully managed otherwise challenges can arise, including: incorrect positioning of the seal on the pallet, concrete ingress between the seal and pallet and compression or displacement of the seal during concrete compaction.

Once the seal is in place within the pipe, it cannot easily be moved or replaced, making it vital that the seal performs as required, first time, to avoid unnecessary lost time and money associated with pipe scrappage.

This is where seal design is so imperative. A seal which is manufactured using co-extrusion methods will ensure high performance. Specifically, slurry lips made of soft rubber – 50 International Rubber Hardness Degrees (IRHD) – will provide improved flexibility and an enhanced seal profile will ensure a more secure fit against the pallet, removing risk of leaking concrete and unnecessary pallet cleaning. To increase stability and grip, the forming parts of the seal should be made from harder material, such as 70 IRHD rubber.

The combination of soft and hard rubbers mean that the seal has optimum stiffness so the profile doesn’t compress, the right level of stability for reduced risk of seal displacement and superior flexibility for the optimum sealing capabilities. In all, a seal with these properties guarantees extended asset and infrastructure life as well as reduced scrap rates.

The Pipeline of the Future

The industry is being driven forward through innovations such as co-extrusion manufacturing technology and automatic pipe laying. This reduces the need for people in the trench during installation, lessening the potential for human error and offering health and safety benefits. Innovation in the form of improved materials, products and installation techniques, is vital in order to continuously improve efficiency, reduce costs and maximize the performance and longevity of pipeline infrastructure. Also important is ensuring that the right standards are specified to meet the needs of each individual job. Working with a partner that can offer a broad view that encompasses understanding the benefits of individual pipes, pipe seals and their performance in context will ensure that the correct product is specified to optimize the pipeline performance.