How life cycle analysis is driving sustainable product development at Trelleborg

Rubber is vital for many industries, from manufacturing and automotive to aviation. However, this versatile material poses significant sustainability challenges due to carbon-intensive manufacturing and extraction processes. To uncover Trelleborg's efforts to minimize the carbon footprint of rubber compounds while maintaining excellent product performance, we spoke with sustainability experts Carl Cumming, Material Development Manager, and Lakshay Vashist, Sustainability Specialist, at Trelleborg.

What is your role at the mixing facility?

Carl: As Material Development Manager, I’m in charge of all material innovation projects at the Forsheda site in Sweden. I’ve worked here for over 14 years, and I’ve spent 30-plus years focusing on material development for rubber compounds. I’m proud of the work that we do here, and I enjoy being part of the team dedicated to creating more sustainable rubber products. Our mission is to establish Trelleborg as the leading supplier of rubber compounds across all product segments, delivering high-quality, high-performance products that provide value for our customers.

Lakshay: Compared to Carl, I am relatively new to Trelleborg. I recently joined the company in January as a sustainability expert. In my role, I carry out detailed life cycle assessments (LCAs) for all the products we manufacture here, as well as for other Trelleborg locations. And while I’m new to Trelleborg, I’ve been working on LCAs for a number of years.

Is sustainable rubber compound innovation something new at the mixing facility?

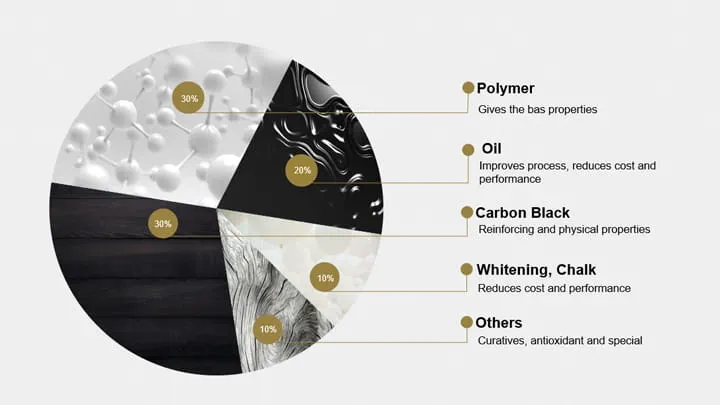

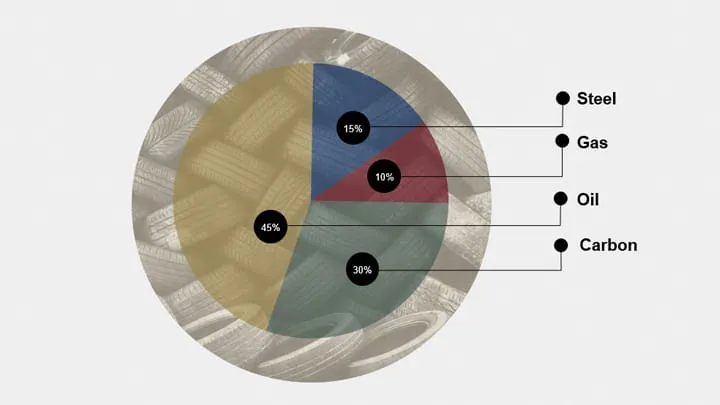

Carl: No, not at all. Since 2021, we’ve been a key part of the broader Trelleborg “Polymers for Tomorrow” task force, which is dedicated to exploring the potential of bio-based materials, regenerated and recycled materials, and new polymer formulas to reduce the environmental impact of rubber compounds. As part of this initiative, we’ve collected valuable data on carbon black, Ethylene Propylene Diene Monomer (EPDM) and oil-based raw materials, and we have kick-started new material development projects with our suppliers and partners.

However, sustainable product formulation and innovation at our mixing facility dates back further than 2021. For instance, we’ve been working for the past 12 years on compounds that use recovered carbon black (rCB), which is carbon black that has typically been reclaimed from end-of-life tires.

What climate and circularity targets has Trelleborg set?

Lakshay: When it comes to setting goals, making sure they are realistic and traceable is key to progress. That’s why Trelleborg asked the Science Based Targets initiative (SBTi) to validate our targets, and they confirmed that our near-term CO2 emissions reduction goals are reasonable by the end of the decade.

Carl: Lakshay is absolutely right. As other manufacturers will appreciate, reducing our Scope 3 emissions will be the most challenging aspect, the vast majority of our total emissions are generated from activities in our value chain, outside of our immediate sphere of influence.

How do LCAs support the work you are doing? And how do you conduct these studies accurately and effectively?

Carl: Running LCAs is more than just an exercise in measuring our internal targets. Our customers and suppliers expect us to back up claims about our more sustainable materials, especially if the sustainable alternative is more expensive.

These assessments enable us to evaluate the sustainability value of products and materials comprehensively, considering factors beyond just the carbon footprint. For instance, when we incorporate bio-based raw materials, LCAs offer evidence to our customers that our practices are environmentally responsible. This means we are not contributing to issues such as deforestation or competition with food agriculture. We present this information clearly through the impact areas identified in our assessments.

How do you balance cost, performance and sustainability when developing more sustainable rubber compounds?

Carl: We recognize that some sustainable products can come at a higher cost, although we will never sacrifice the high quality of our products..,. Generally speaking, the lower the carbon footprint of a product, the more expensive it is to produce. So, to empower each of our customers to improve their environmental impact, we offer four different types of sustainable rubber compounds:

- Compounds that use recovered carbon black (rCB) instead of virgin carbon black

- Compounds that use rCB black and recycled oil

- Compounds that use rCB and a circular or recycled polymer

- Compounds made from rCB, recycled oil, circular or recycled polymer

Lakshay: For each compound , we offer the same traceability and transparency with data fully backed up with detailed LCA studies covering cradle-to-gate CO2 emissions.

Do you think Trelleborg can meet its climate goals?

Carl: I’m impressed with how far we have come in recent years. Even small changes like switching from hydraulic to electric motors and using LED lights helped us to reduce our energy consumption by 80% almost overnight at the mixing facility.

It is not going to be a walk in the park. For example, reducing our manufacturing-based Scope 2 emissions can be challenging in regions where there’s limited access to renewable energy. To reduce our Scope 3 emissions, we will need to continue working with our customers and partners to maximize sustainability, performance and affordability.

If we keep this up, I am confident we can meet our goals.

To find out more about sustainable rubber compounds from Trelleborg, get in touch with one of our experts today.

Our team - How can we help?

Carl Cumming

Material Development Manager Get in touch with Carl concerning questions related to rubber compounds.