Trelleborg’s engineers take the time to consider the design of the insert in conjunction with the characteristics of the resin material, and the functionality of the part to produce high-performance medical devices.

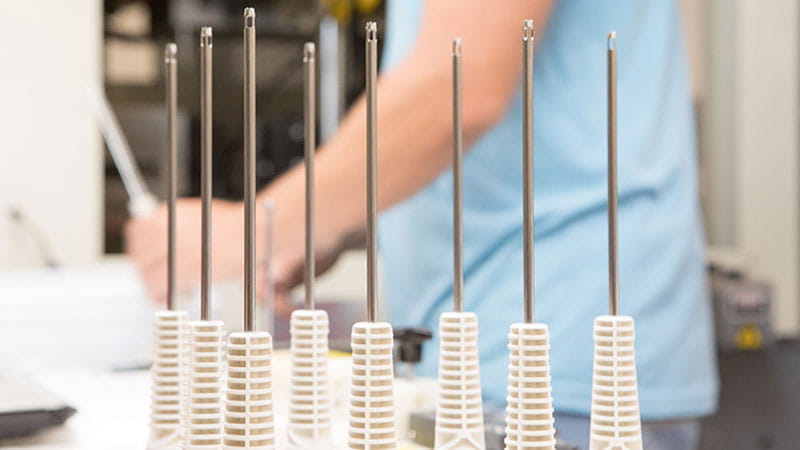

Insert molding introduces metal tubes, shafts and blades, as well as ceramics, cables, connectors, printed circuit boards (PCBs), thixo and a variety of other materials into injection molded medical devices, allowing for the utilization of each material’s unique physical characteristics.

Through insert molding, we can achieve outstanding results by combining drastically different materials into the same device.