LSR Multi-Component Solution

Improving performance reliability at reduced cost with a custom-engineered solution

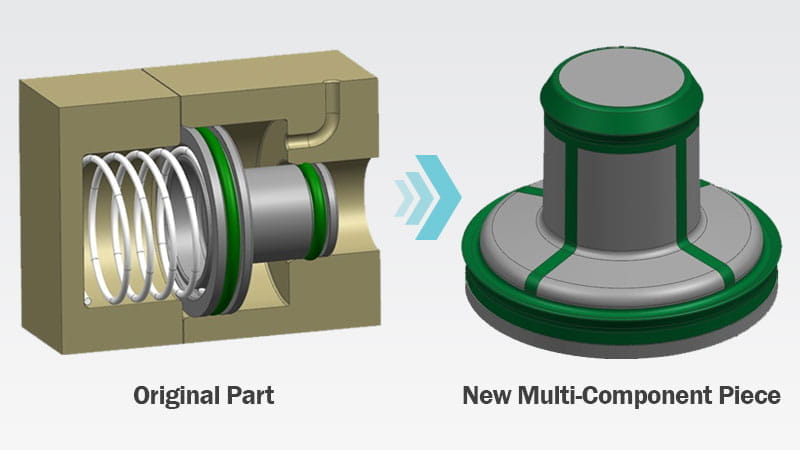

Application: Spring-activated piston for medical micro-pump system

The customer had designed a control valve with a spring-activated thermoplastic piston, sealed with two standard silicone O-Rings. They turned to Trelleborg Medical Solutions for assistance to analyze and resolve a leakage problem, while also aiming to reduce friction within the system.

Trelleborg Medical Solutions engineers partnered with the customer every step of the way to replace a poorly performing 3-piece piston assembly with a new multi-component solution:

- Thorough analysis of existing components, mating environment, assembly process and application were undertaken to identify the potential sources of leakage and friction.

- Finite Element Analysis (FEA) simulations created to better understand how the part was reacting within the application.

- Key issues were identified as:

- Misalignment of the plastic piston as a result of poor quality tooling and process control are creating potential leakage path in application

- Automated O-Ring assembly reliability not 100% guaranteed

- Stack-up of tolerances between piston, O-Rings and piston housing creating increased friction

- Mating surfaces and materials not friction optimized

- A new multi-component LSR part was designed to address above root cause of the leakage and friction issues.

- Compressive inner sealing for pressure both sides

- Deflective outer sealing to reduce contact friction and for pressure energized seal

- Provide inner and outer guiding

- LSR seals chemically firmly bonded to PA piston

- Integrated channels to flow LSR for easier injection

- The new design was subjected to FEA simulations to ensure optimum performance.

- A design for manufacturing (DIM) analysis was performed including material flow simulation to ensure manufacturing feasibility

- Prototype tooling was developed utilizing our state-of-the-art in-house tool making and process engineering capabilities for production of test samples

- Customer’s manufacturing process was addressed and key changes suggested to ensure consistency.

Successes

Partnership during the design phase led to collaboration on product and component design, materials selection, manufacturing.concept development as well as validation.

The new, multi-component LSR part solved leakage and friction issues and provided a fully functional and reliable design.

The integration of three individual components into a single one eliminated steps in the customer's supply chain and manufacturing process, and thereby led to an increase in the customer's product quality and reliability at reduced production risk and overall lower costs.