Overview

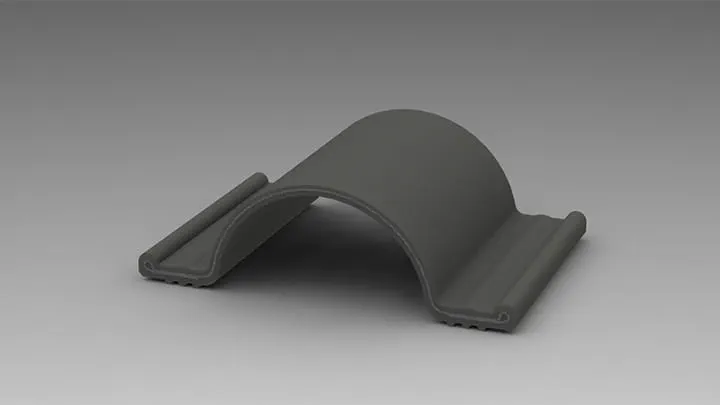

The Omega Seal is designed as a secondary seal for immersed tunnels in combination with the Gina gasket/seal as the primary seal

Applications for the Omega seal have now expanded to bored tunnels, aqueducts and ship lifts. Using the same construction techniques and materials as utilized in the original Omega shaped seal, the range has been expanded to flat seals. The Omega seal provides the unique properties to withstand high water pressure in combination with large movements in all directions. The Omega seal provides an ideal solution for joints where large gap movements are expected as a result of temperature effects and/or settlement.

The construction of the standard Omega seal consists of 2 nylon plies with SBR rubber cover on inside and outside. The allowed movement of the Omega depends on the pressure differential across the seal and the strength of the plies. In general the Omega is designed to allow axial and radial movements and/or rotation of the two bridged structures.

Trelleborg is able to calculate the force-compression curves and elongation limits at various water pressures