Orkot® Hydro Bearings

Date: 17.10.19

As the world invests more into renewable energy sources, manufacturers are looking for ways to improve the efficiency and reliability of hydroelectric dams.- Jan Sklucki

IN SHORT

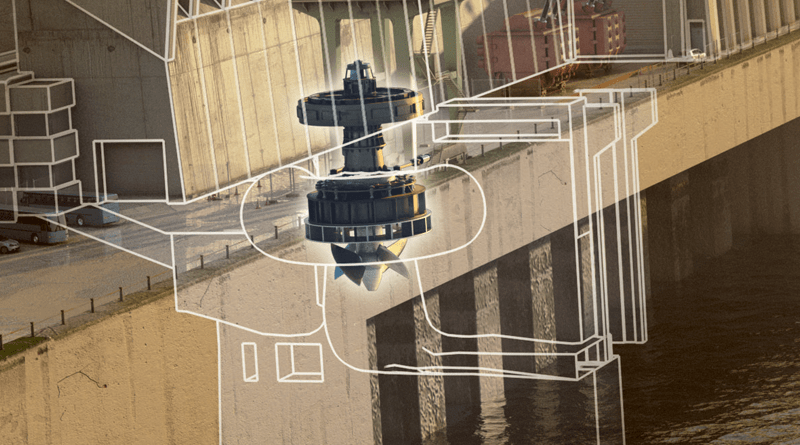

- Bearings are a key component of many different parts of hydroelectric dams.

- Orkot® TXMM and TLMM withstand extreme loads and are environmentally friendly, generating less friction and wear.

- Testing and qualification give confidence that the bearings will meet requirements

ITG_Hydropower_Orkot Hydro Bearings_Hotspots-Hotspot

Testing and Qualification

Key to confidence in its bearings are Trelleborg’s advanced testing and qualification laboratories. “We can replicate applications in our lab and ensure that the product performs as it should,” says Alexander. “This lets us reduce the time to market for a custom product and show engineers exactly how it should work.”

On offer are compressive tests with 100kN loads, rotary friction and wear rigs with 300 m/min speeds, and linear testing up to 20 m/min. These can run customer tests to ensure products meet requirements or help ensure internal production quality.

FIND OUT MORERead the Orkot® Hydro Bearings Engineering Manual.

www.tss.trelleborg.com/literature