Fluid Power

Zurcon® Buffer Seal has been optimized to operate as a primary rod seal for heavy-duty applications, such as lift trucks and earthmoving equipment.

Tests show that using a Buffer Seal manufactured from Zurcon® polyurethane with wear inhibitor and partner lubrication reduced compression set behavior and friction by almost 50%. By considering lubrication management, it has significantly improved performance and wear resistance in the secondary seal.

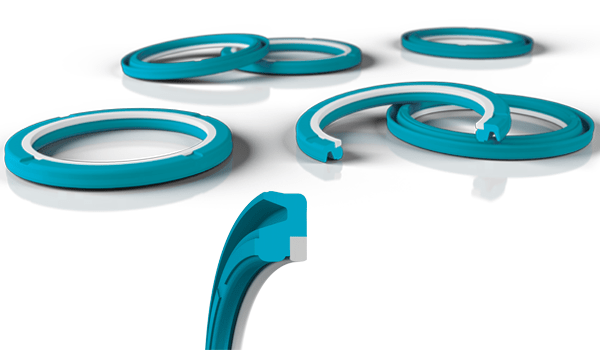

The seal has a number of innovative features to increase performance. It uses a combination of materials to extend the service life. The main sealing lip is manufactured from Zurcon® material, but is accompanied by a solid antiextrusion ring made from a hard thermoplastic. In addition to this, it incorporates radial slots and channels to avoid blow-by effects and a dynamic lip design to minimize friction and ensure back-pumping.

The shape of the lip guarantees optimal pressure distribution across the seal and constant lubrication. When un-pressurized, slots within the seal ensure that blow-by cannot occur. When pressurized, a relief mechanism kicks in to level pressure and ensure adequate lubrication of the whole rod.

“These kind of designs feature a lot of technology and are backed-up by finite element analysis and field testing, so both theoretical and empirical proof,” says Alberto.

The result of continuous development in the form of material and design improvements, the Zurcon® Rimseal IM is an O-Ring energized seal profile that comes as a result of continuous development of sealing systems with lubrication management principles in mind.

The design and material of Zurcon® Rimseal IM are optimized to take advantage of tandem seal teamwork. By deeply studying the contact pressure distribution and its variations performance has been optimized, particularly with respect to sealing ability and friction.

Zurcon® Z13 was chosen due to its mix of favorable physical-mechanical characteristics and chemical resistance.

“Zurcon® Z13 was an excellent choice of material to start with for the next generation of seals. It allows injection molding or lathing, keeping the pricing competitive.

When this seal is combined with lubrication management, the friction reduction is even more significant for the whole system,” finishes Alberto.