Moving Parts

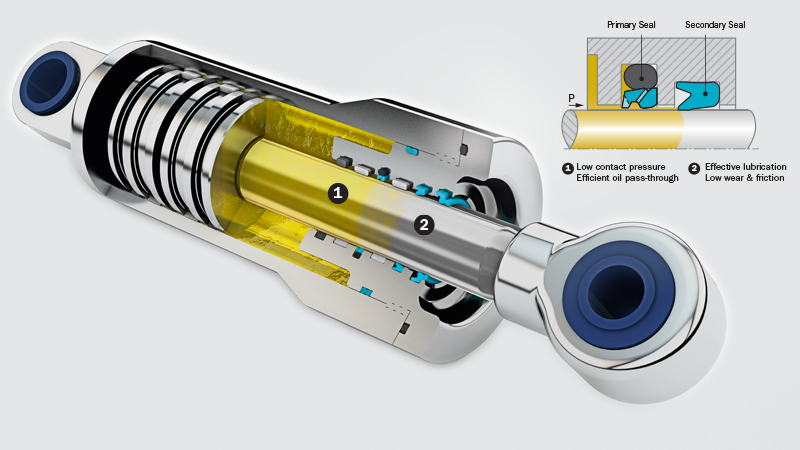

Mandy, continues: “If the primary seal does its job perfectly for an extended time, no lubricant goes past it. This generates dry running conditions for the second seal and, should it activate, creates wear. Lubrication Management solves this issue by balancing the risk of lubricant leakage to ensure both the performance of the primary seal and extend the life of the secondary seal.”

Extending life and more developments

Lubrication Management technology incorporates rounded sealing edges that lower contact pressure and allow just enough fluid to enter the system to sufficiently lubricate the piston rod. This increases the consistency of the tribological system between the sealing configuration and its counter surfaces, reducing friction and wear, and significantly extending application life, while increasing robustness and reliability.

Though Lubrication Management represents a revolutionary step in fluid power sealing, the future holds even more exciting innovations.

FUN FACTS

Kroll K10000 is the highest freestanding tower crane at 470 feet, with a jib reach of up to 330 feet and an area covered of 7.5 acres.

Liangzhu, China, is home to a series of high and low dams, and levees built 5,000 years ago, making it one of the world’s oldest-known hydraulic engineering systems.

Bucyrus RH400 is the largest front-shovel excavator, weighing around 889t with an 8.6-meter-wide under carriage.