Putting the Pieces Together

Manufacturing processes are highly complex. Not only do they require a wide variety of tools and equipment, computers, software and sometimes robots, but they also need people with a broad range of skills and knowledge.

Businesses are continuously looking to optimize these processes to increase production throughput without increasing costs.

Supporting our customers

“At Trelleborg Sealing Solutions, we partner with customers to understand how their products are manufactured and what their goals related to the assembly process are,” says Uwe Haehnel, Director Lead Group ServicePLUS Europe.

“Together, we identify and develop a custom approach to help them meet their production goals. Each manufacturing process is unique, so no one solution fits all.”

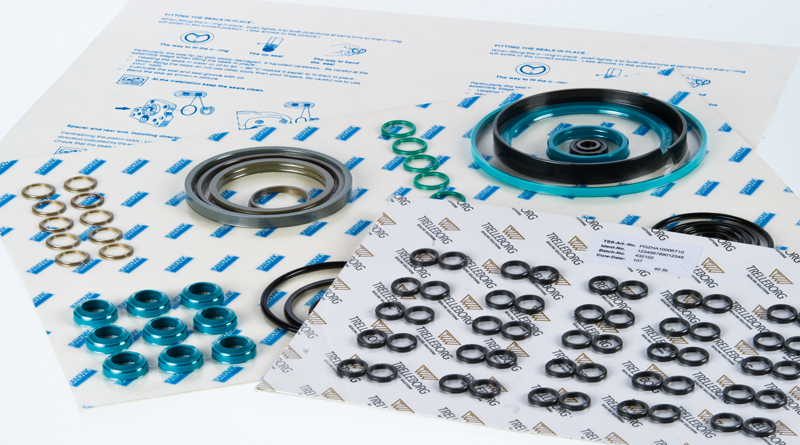

To meet our customers’ needs, the ServicePLUS concept was developed. This is a “total solution” program that can simplify the workflow in every part of our customers’ value chains. A variety of enhanced services match our customers’ needs at every step of the business process, ultimately reducing total costs and throughput time.

“Supporting optimization of our customers production processes can mean many things,” explains Uwe. “For some it can be about identifying and solving problems that arise during assembly. For others, it means we functionally take over portions of this process, including consolidation of suppliers, subassembly and quality testing. Whatever the challenge, we are committed to finding a solution.”

Here is one real life situation where a ServicePLUS solution came to the rescue.

In a highly automated manufacturing process, O-Rings were installed into hardware automatically and were coated with talcum powder to prevent the elastomer from sticking to the automated machine and slowing down the assembly process.

Since the O-Ring was used in a dynamic application, silicone oil was also added to the component during production. The combination of talcum powder and silicone oil led to a buildup of sludge in the manufacturing equipment, which resulted in substantial cleaning cycles, slowing down the entire process.

Trelleborg engineers worked closely with the customer to develop a solution that did not interrupt the assembly process and reduced downtime costs for the cleaning cycle. In this case, a special

surface treatment was applied to the seals that prevented the elastomer O-Rings from sticking during assembly and allowed them to operate effectively in their dynamic application.

THE ServicePLUS SOLUTION

Often seals are installed into hardware manually. The correct installation of seals can be tricky and, since seals play a critical role in applications, there is no room for error.

“A first-time customer recently reached out to us,” says Uwe. “They were experiencing difficulties with manual seal installation. We worked with them to quickly supply a customized assembly tool for their case. This solution provided the customer with a way to enable component quality with safe installation, and the quick turnaround time meant they were able to stay on schedule.”

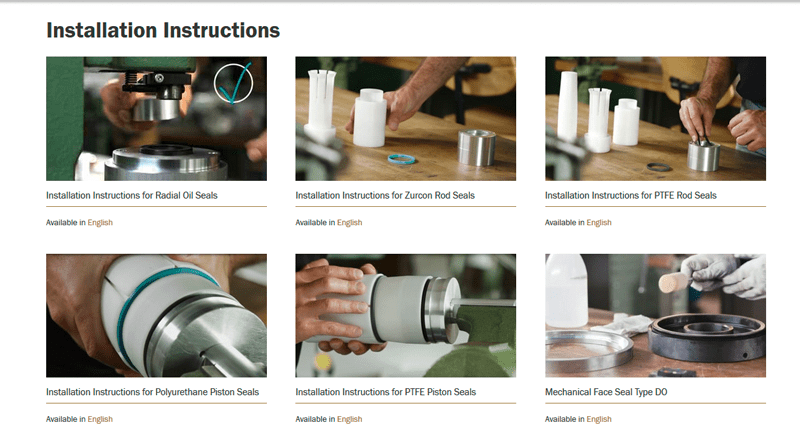

The new ServicePLUS assembly tools service is designed to ensure that seals are installed correctly. Customers are provided with a custom package of assembly tools that can, upon request, be engraved with a QR code linked to relevant information, such as assembly instructions, installation films or other related documents.

To watch the assembly tools in action in our installation instruction films, click here.