Get me to the Line on Time

THE CONCEPTS OF JUST-IN-TIME INVENTORY MANAGEMENT AND LEAN MANUFACTURING

can be traced back to Japan in the 1940s, when the shipyards had very few financial resources and so sought ways to minimize their inventory costs. The practice later became popularized worldwide by automaker Toyota.

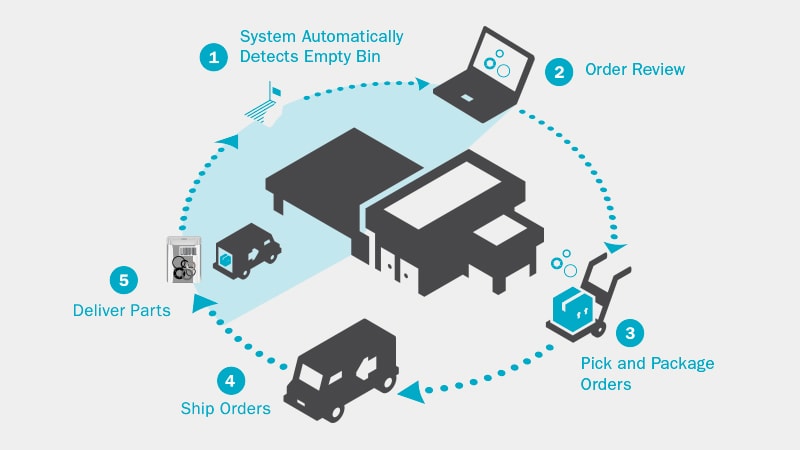

While techniques have changed, the basic concept remains the same: have just enough inventory on hand to keep your assembly lines humming, but not so much that you are needlessly using funds that could be more efficiently put to work elsewhere. That requires efficient monitoring of inventory levels and fast ways to order more before a plant runs out of the parts it needs to operate.

“I think it’s pretty exciting and will contribute to our growth strategy over the coming years.”

Unlike other advanced delivery options, the IntelliStok® solution is designed to fit existing rack and bin systems without modifications. It eliminates the need to manually check or scan inventory and so has the potential to save thousands of dollars in labor costs each year.

The unique IntelliStok® system fits nicely into the Trelleborg Sealing Solutions service model, ServicePLUS, and it will contribute to our growth strategy over the coming years.

By providing services such as this, we can help customers focus on their core competencies. Offering more services can mean doing some sub-assembly work, such as inserting a seal into a piece of metal that goes on to be combined into a larger part, or it can mean streamlining a customer’s internal operations to reduce costs and increase efficiencies, as IntelliStok® does.

Left: Will Bacon with Bill Shirk, ServicePLUS Center Lead and IntelliStok®, a pressure-based sensor pad which sits in the bottom of a parts bin.