Resisting the Clean

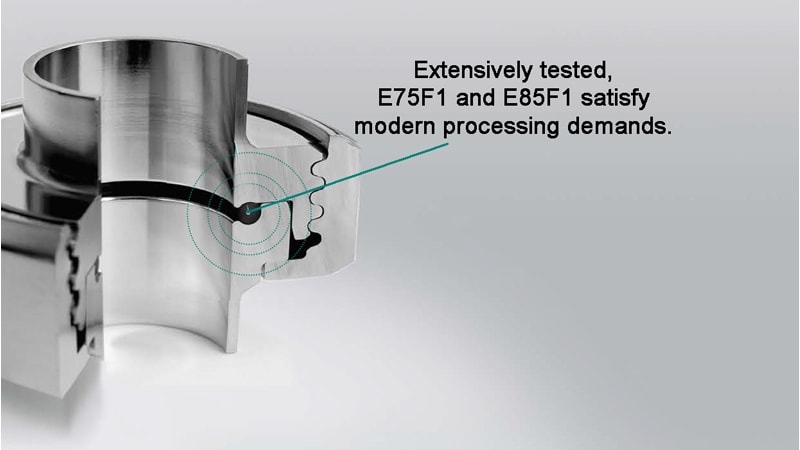

to create new products and materials to optimize application performance. Solutions are specifically engineered to meet compatibility and cleanliness requirements outlined in FDA, USP Class VI and EC 1935/2004 guidelines. Further evolution in processing environments, chemicals used and standards for food-contact materials continues to drive innovation, which has led to the development of E75F1 and E85F1.

“We have invested significant resources into R&D to ensure our materials meet the requirements of national and regional standards and demanding cleaning regimes,” says Giuseppe Pezzulla, Product Manager O-Rings, at Trelleborg Sealing Solutions. “The fruits of our labor have improved performance in many applications. Our latest EPDM compounds are no exception.

A large part of the R&D program has involved extensive testing of E75F1 and E85F1. “These new compounds offer unparalleled resistance to chemicals used within cleaning and sterilization regimes, including polar solvents, alkaline cleaning fluids, steam and hot water. Our testing has proven that these materials are the best-in-class for dairy applications and Water-For-Injection (WFI) applications at high temperatures,” says Giuseppe. By using the smallest possible amounts of additives, leach out is kept to a minimum, lowering the risk of contamination, while still achieving the necessary chemical and thermal stability.

The compounds can be applied to seals used in a number of food, beverage, healthcare and medical applications, including drug delivery systems, filling machines and CIP/SIP cleaning equipment. By allowing seals to be manufactured via compression or injection molding, many different solutions can be supplied. “We’re recommending that customers substitute E7502 and E8502 with the new compounds in new applications to provide greater performance and long service life.” finishes Giuseppe.

| General Data | E75F1 | E85F1 |

|---|---|---|

|

Basic Polymer |

EPDM |

EPDM |

|

Color |

Black |

Black |

|

Temperature Range |

-45 °C / -49 °F to +150 °C / +302 °F | |

|

Hardness |

70 ± 5 Shore A |

80 ± 5 Shore A |

|

Density |

1.20 ± 0.03 g/cm3 / |

1.22 ± 0.03 g/cm3 / |

|

Approvals |

Hardness FDA 21 CFR 177.2600 |

All EPDM grades are peroxide cured and contain a very low amount of softeners and process aids. This reduces potential leach out to a minimum, lowering the risk of contamination. They have also been engineered to achieve enhanced chemical and thermal stability along with compliance to a variety of healthcare, medical, food, beverage and pharmaceutical standards and approvals.