Pumping Away

WE WORK WITH PUMP MANUFACTURERS

to maximize the performance of their products. Our engineers work directly with the customer to identify needs and recommend seals based on operating parameters and the media in the pump.

Meeting all pump sealing needs

Pumps are a vital component in any hydraulic system, and they come in a range of different sizes, depending on the demands of the equipment. For example, there are large, high-pressure pumps in mining equipment and delicate, miniature pumps in medical devices.

One function of seals in pumps is to prevent leakage of fluid being pushed through the pump to the rest of the hydraulic system under harsh conditions and high pressures. As hydraulic systems use various media, ensuring chemical compatibility is crucial in a hydraulic system to maintain integrity. For example, the Turcon® Varilip® PDR replaces radial oil seals in aggressive fluids to extend system life.

Supporting customers to develop new products

Many of the sealing solutions we offer for pumps are from our existing extensive seal and material portfolio. But when our customers are working on innovative pump technology, including novel designs or incorporating new media, we can work with them to develop alternative seal geometries and materials. Depending on customers’ needs, our global R&D facilities support with a full range of services, from product and material development to testing. We also offer rapid prototyping services with expedited delivery to provide our customers with seal prototypes for their own test procedures.

Digital tools to support the engineer

The best solutions are based on early consultation between customers and our engineers. Nowadays, when working relationships are more on-line, pump designers can benefit from using our digital tools, all of which are free-to-use. There are a few that I use frequently. Firstly, the Hydraulic System Calculator, which supports engineers with a wide range of calculations. The O-Ring Calculator is one of the most useful tools we offer. Not only does it help people calculate O-Ring and housing dimensions, but it also recommends O-Ring sizes and part numbers, making the specifier’s job easier.

TOOLS & APPS FOR DESIGN ENGINEERS

Hydraulic System Calculator

O-Ring Calculator

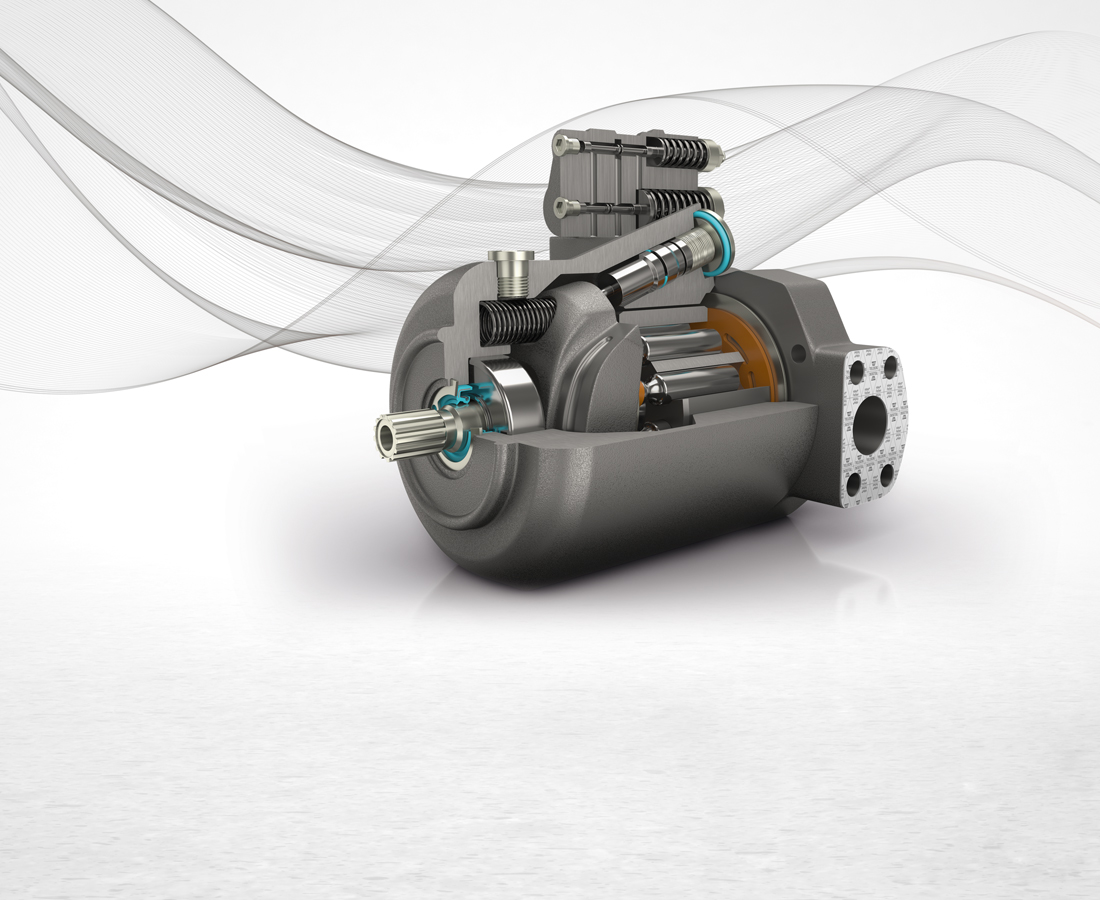

Pumping solutions

Pumps provide the source of power in hydraulic systems. They use rotation to create fluid flow and generate pressure, which delivers hydraulic energy to the rest of the system. A variety of seals within the pump prevent leakage and contamination from external media entering the hydraulic system. At the same time, they ensure uninhibited function of the pump with low friction and wear. Sealing solutions, optimized for pump applications, can potentially extend the service life of the pump and also the equipment it operates in.

Pumping Solutions

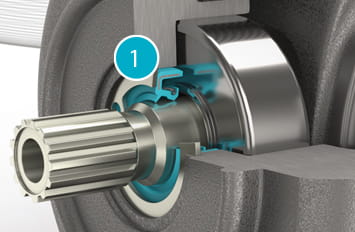

Typical seals: Radial oil seals prevent leakage from the drive shaft during pump operating cycles and exclude ingress of contamination with an externally facing dust lip.

Turcon® Varilip® PDR offers stick-slip-free running and is suitable for high surface speeds with low pressure. Turcon® material is compatible with a variety of media and operates in a wide temperature range.

The HP20 rotary oil seal is an elastomeric seal suitable for sealing medium to high hydraulic oil pressure at low to medium shaft speeds. Available in FKM and HNBR for

standard and low temperature environments.

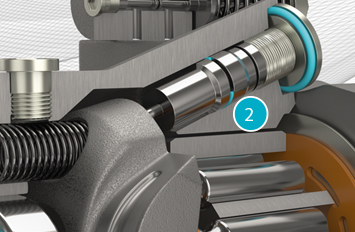

Typical seal: The Turcon® Glyd Ring® is a low friction, abrasion -resistant seal that allows the positioning cylinder to function reliably as needed over a long period of time.

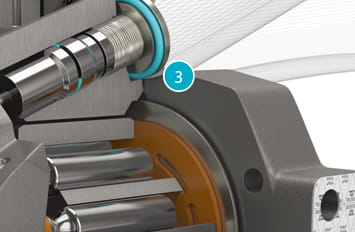

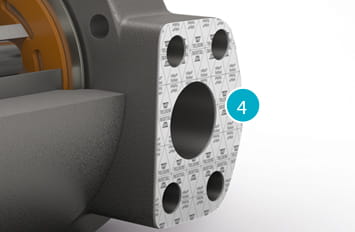

Typical seals: O-Rings are available in a wide range of elastomer materials for both standard and special applications.

Typical seal: HiMod® FlatSealTM 15, part of Trelleborg’s range of flat gaskets, offers exceptional performance in pump and other hydraulic component applications.