Plastic Fantastic

THE AEROSPACE INDUSTRY is continuing to evolve and there is a long-term trend toward using more engineered injection molded and machined parts in aircraft. According to Stratistics MRC the global aerospace plastics market accounted for 12.32 billion USD in 2017 and is predicted to reach 26.79 billion USD by 2026; an annual growth rate of 9%*.

The same report points to the main drivers as a rise in the number of aircraft manufactured, increasing demand for lightweight components and growing demand for plastics in several aerospace applications. However, the high cost of fabrication and a limited range of material options are hampering the market.

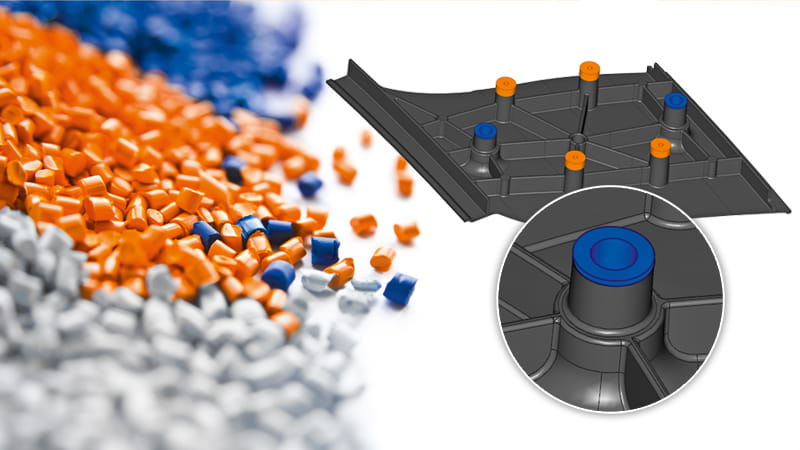

To counter that limitation, injection molding represents an effective and efficient option for production of plastic components. Sometimes thought of as weak, the latest plastic innovations in terms of materials and processes, mean that even structural metal parts can be replaced with injection molded alternatives.

“There are numerous advantages associated with ultra, high performance, and engineered polymers,” says Tim Miller, Technical Manager at Trelleborg Sealing Solutions. “These advantages include lighter weight, inherent flame resistance, excellent impact resistance, and low moisture absorption. More and more traditionally metal parts are being replaced with plastics and this trend will continue as the industry looks for lighter weight and more cost-effective solutions.

“A focus on material technology and processes to make production of plastic parts ever more effective, will no doubt contribute to spurring the market along.”