Future Sensing

A three-way partnership is showing how big data can work to develop next generation solutions. Domenico Tucci (DT) interviews Vapo Hydraulics and Ampelmann Operations

Vapo Hydraulics has been involved in custom-hydraulics since 1974 in several industries. Wouter Vullers (WV) is the Commercial Director at Vapo Hydraulics NV.

DT: What trends are you seeing in the hydraulics market currently?

WV: We see more and more customers are interested in adding sensors to their hydraulic equipment. This is not only in offshore environments, but also on dredging equipment and civil works, like bridges, as well as on industrial equipment, for example presses.

These sensors can not only be used in normal operating conditions to monitor capacity, speed or force control, but also to collect and analyze data to prevent certain failure modes.

This helps customers avoid significant costs associated with downtime, as well the replacement or repair of key components.

DT: What are the sort of conditions that you are seeing our seals and bearings facing within hydraulic environments?

WV: In the offshore environment they face extreme temperatures and need to survive in saltwater. They are also subjected to a dynamic load spectrum that influences both seals and bearings.

DT: Putting the collective minds together of the engineers, data scientists and IoT specialists of Vapor Hydraulics, Amplemann Operations, and Trelleborg Sealing Solutions, we’ve managed to deliver value. Would you agree with that statement?

WV: This three-way open communication gave us all a chance to bring our experts to the table to create and stimulate us to move to the next level of root cause analysis.

For our company, this helps us to develop new products and update existing ones, so we can support the customer to produce a better product in the future.

Ampelmann has an established presence in every major oil & gas and offshore wind market. Jochem Pieterse (JP), Head of Reliability at Ampelmann Operations, talks about the project.

DT: Can you tell us what Ampelmann does?

JP: At Ampelmann we have a solution for safe transfer of people and cargo to offshore structures; a typical assignment for helicopters and crew transport vessels, for instance.

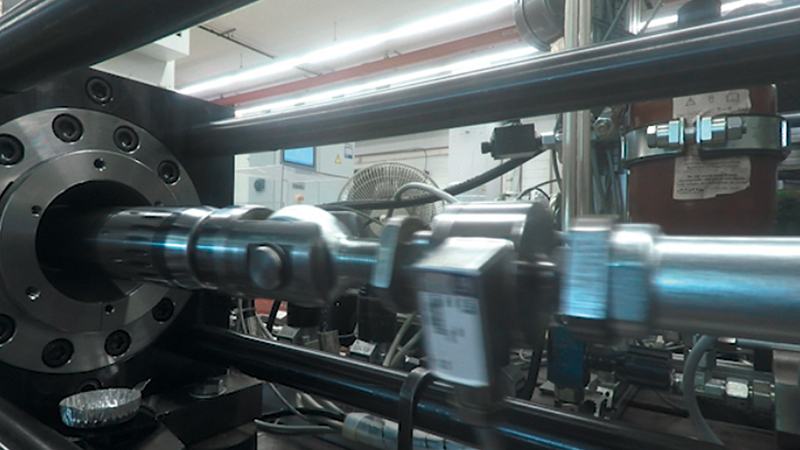

DT: It was certainly a fascinating project for me. It was the first time that I have encountered this type of application. On the gangways that you provide you have cylinders, which are fitted with numerous sensors gathering data on how these cylinders are operating. That’s the data that you’ve supplied to us. Our engineers and our data scientists worked with your team. What were you hoping to achieve?

JP: We have data available from all sensors in our systems, and this is mainly used to operate them. In the project, we wanted to use this data for other applications, such as the prediction of failures and the condition monitoring of critical components.

DT: What about initial results?

JP: In terms of results so far, we have some good first algorithms that need to be statistically proven, as well as some key sensor data that was missing from the data sets. These can now be added to new cylinders to give a more comprehensive field of data sets.

DT: I think that both companies have learned from this project and I am looking forward to what we are able to achieve now that we have made changes to the way data is being collected. Hopefully, we will be able to help optimize the performance of your cylinders and predict any possible problems going forward.

MORE ABOUT COGNITIVE SEALING

Go to our web page dedicated to Cognitive Sealing at www.tss.trelleborg.com/cognitive-sealing to find out more

As IoT and big data can offer significant benefits in terms of improving product performance, lowering total cost of ownership and extending application life, it is becoming an area of focus in almost all industries. This includes the offhighway industry. Johannes Kunze von Bischhoffshausen, the Trelleborg Sealing Solutions manager for digital transformation, tells us more.

Keeping equipment available

In the off-highway industry, keeping equipment availability as high as possible is crucial. Planned downtime needs to be kept to a minimum and unplanned downtime should be

avoided. Therefore, predictive maintenance is one of the big value drivers in the digitization of this industry. Maintenance must not be too late, as this incurs extremely high costs in downtime, nor too early, to reduce maintenance costs overall.

Even though we at Trelleborg provide the best sealing solutions possible for even the harshest of off-highway applications, the seal is still often the weakest link in a hydraulic system. In the Cognitive Sealing approach, we use artificial intelligence to calculate a health score by analyzing sensor data that is captured around the sealing system.

A health score

This is done using artificial neuro-networks, an advanced technique used in autonomous driving, for instance. This is needed as you cannot simply look at one sensor signal but must combine the data from different sensors, such as temperature, pressure, and cylinder movement. An algorithm then calculates the health score for the sealing system.

We are currently focusing the Cognitive Sealing approach on those industries and applications in which there is a very high cost of downtime and maintenance. In off-highway applications, most maintenance happens on a fixed maintenance cycle and generally the seals are changed in this cycle.

Automation driving need for intelligent systems

However, there is one big trend in the off-highway industry which makes management of the sealing system and monitoring seal health much more important, and that is automation. This is being brought into equipment for mining and excavators, for instance. Without a driver, you need another way to monitor the system with better remote monitoring.

WATCH THE PODCAST IN FULL

Dr.-Ing. Johannes Kunze von Bischhoffshausen joined the July 22 OEM Off-Highway video podcast to discuss how Trelleborg uses artificial intelligence to improve predictive maintenance to help prevent unplanned downtime in heavy equipment. Interest in this topic is fueled by growth in the autonomous equipment market. To view the podcast, follow the link below