Surface Coating

IN SHORT

- Shock absorbers are critical to good control and safe handling, but friction is an issue.

- Seal-Glide® Nano is ten to 50 times thinner than typical coatings and reduces friction and stick-slip.

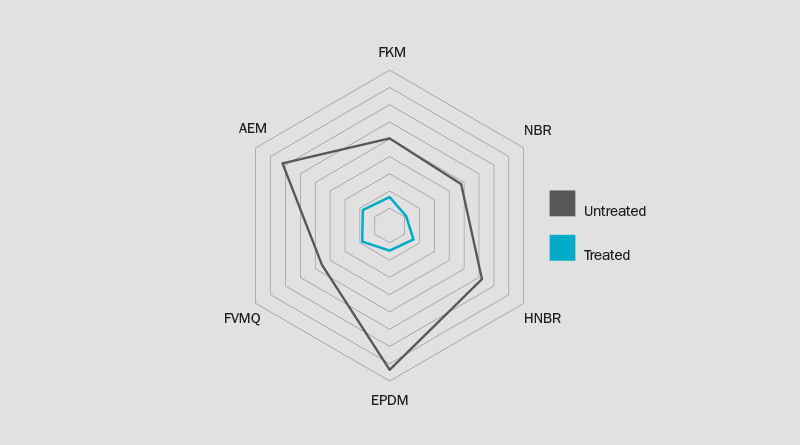

| Material | Untreated | Treated | Treated and Aged | Test Conditions |

|---|---|---|---|---|

|

FKM |

1.01 |

0.33 |

0.51 |

Air aging (168hrs/+200 °C) |

|

|

|

|

0.48 |

IRM 903 (168hrs/+100 °C) |

|

|

|

|

0.37 | FAM-B (168hrs/+60 °C) |

|

NBR |

0.96 |

0.22 |

0.26 |

Air aging (168hrs/+100 °C) |

|

|

|

|

0.23 |

IRM 903 (168hrs/+100 °C) |

|

HNBR |

1.24 |

0.32 |

0.29 |

Air aging (168hrs/+100 °C) |

|

|

0.38 |

IRM 903 (168hrs/+100 °C) | ||

|

EPDM |

1.67 |

0.26 |

0.29 |

Air aging (168hrs/+100 °C) |

|

|

0.32 |

Havoline: Water 1:1 (168hrs/+135 °C) | ||

|

|

|

|

0.59 |

DOT4 (168hrs/+125 °C) |

|

FVMQ |

0.91 |

0.37 |

0.59 |

FAM-B (168hrs/+60 °C) |

|

AEM |

1.28 | 0.36 | 0.26 | Air aging (168hrs/+100 °C) |

They ensure good control and safe handling by damping unwanted body movements and maintaining constant contact with the road for tires.

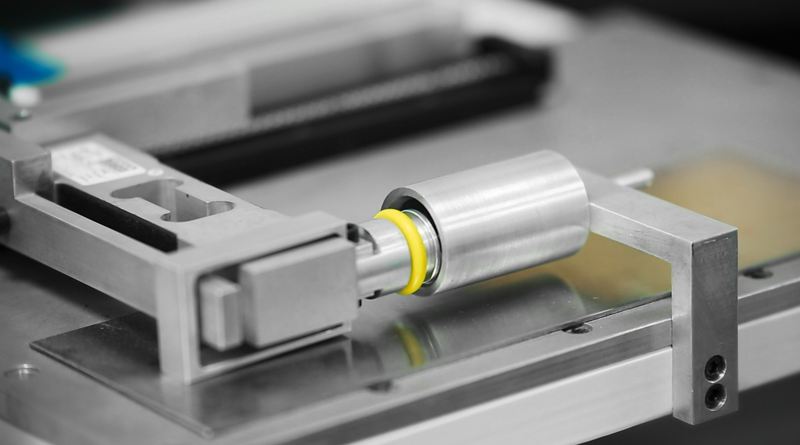

A typical challenge for shock absorbers is friction, both during assembly and in operation. This negatively affects manufacturing and vehicle performance. A solution is Seal-Glide® Nano, a coating specifically designed to reduce friction.

Seal-Glide® Nano was developed jointly by Trelleborg Sealing Solutions in Malta and Stuttgart, Germany. Manufacturing and research & development specialists joined forces to create added-value for automotive partners and customers supplied in high volumes.

Trelleborg Sealing Solutions invests heavily in research and development worldwide. Malta and Stuttgart represent two of eight global centers of excellence.

Our facility in Malta, the lead high-volume manufacturing site specializes in the development and production of O-Rings, engineered molded parts and multi-component solutions.

Watch our film about advanced sealing solutions capabilities of Trelleborg Sealing Solutions Malta, click here.