High Hopes

IN SHORT

- SAPH, based in the Ivory Coast, is an important supplier of rubber to Trelleborg.

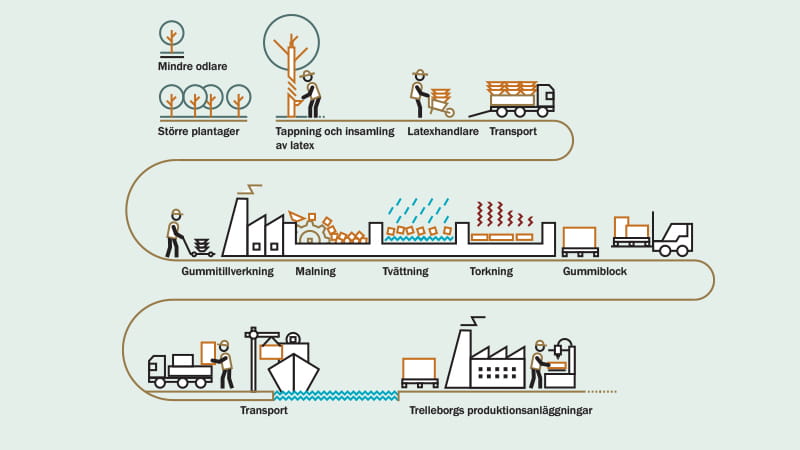

- The production of rubber involves stages such as washing, mixing, cutting and drying.

- Initiatives, such as water recycling, are in place to reduce damage to the environment.

- Employees get many benefits, including free water and electricity, schools, and education

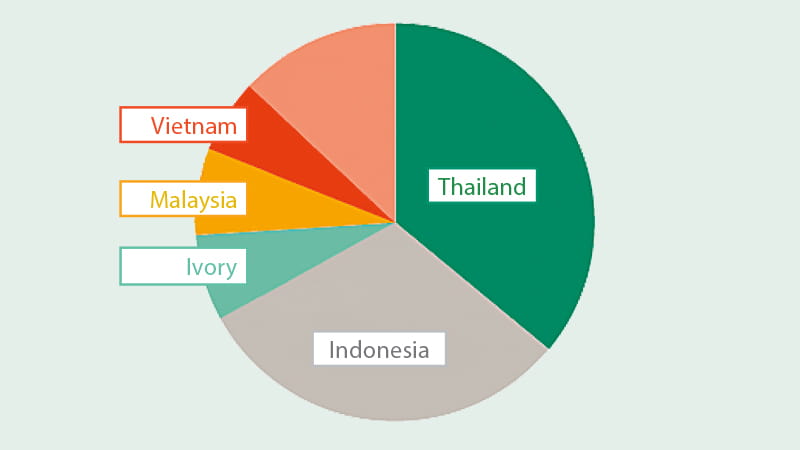

almost half the rubber used by the manufacturing industry is natural. While Thailand and Indonesia are the two biggest producers of natural rubber, the third country on the list in terms of net exports is the Ivory Coast.

Harvesting rubber

SAPH, is an important supplier of natural rubber to Trelleborg. Its natural rubber producer in Bongo, in the southeast of the Ivory Coast, is the largest in Africa and capable of producing 56,000 tonnes of natural rubber per year.

Rubber can be harvested every month of the year except January and February. Siphoned off from the Hevea Brasiliensis tree, the raw materials are collected in a cup, where they coagulate to form what is known in the industry as a “cup lump”. The color of the cup lump changes depending on how much time it spends drying out in the sun, becoming more yellowish-brown with increased exposure and oxidation.

SAPH Quality Manager, Etienne Bertrand, says:

“The first step we take with a batch is quality control – to check that the raw material contains enough usable rubber. After that comes the washing, mixing, cutting and drying process.”

“ The first step we take with a batch is quality control – to check that the raw material contains enough usable rubber.”

Another positive result of SAPH’s CSR efforts is that the villages neighboring the ones owned by the company also benefit. They can also use the health center and receive advice and help from doctors and nurses, for example during childbirth. In general, the quality of equipment here is higher than at the equivalent state-owned health facilities.

Many other services that the state would usually provide are taken care of by the large rubber producer in this region – and access is not limited to those living in the company’s villages.

In the areas just outside these villages, SAPH provides support to high schools in the form of materials and the construction of new buildings. The company also builds school canteens with support from local women’s groups for food supply and preparation, using the motto “ a hungry belly has no ears.”

An entire ecosystem has sprung up around the facility in Bongo. And the operation has given independent rubber farmers a chance to earn an income that is better than if they were growing cacao, which you can only harvest twice a year.

“There really is no alternative. We have to take on a great deal of responsibility, otherwise it would be impossible to run an operation as large as ours, with almost 1,300 employees.”

- Thailand: USD 6 billion (36.2%)

- Indonesia: USD 5.1 billion (30.7%)

- Ivory Coast: USD 1.1 billion (6.7%)

- Malaysia: USD 1.1 billion (6.6%)

- Vietnam: USD 1 billion (6.1%)