All the Fun of the Fair

Globally we try to engage with our audience and while showing them the lighter side of sealing, communicate some sophisticated and important concepts and ideas that can ultimately make our customers’ products perform more effectively.

Theme park design, with interactive exhibits

At Hannover Fair, we presented a series of interactive, themed 'islands' providing information about materials and production competencies. To emphasize the advantages of working with us, we used several methods. Virtual reality headsets took visitors on a tour of one of our manufacturing facilities. A large-scale 3-D projection screen presented Trelleborg's World of Seals visually alongside a large highlight table positioned centrally that displayed the Trelleborg Sealing Solutions Hand-in-Hand collaborative engineering concept.

“It is not only key for us to present our ideas and concepts to our customers but also to engage and inspire the engineers of the future.”

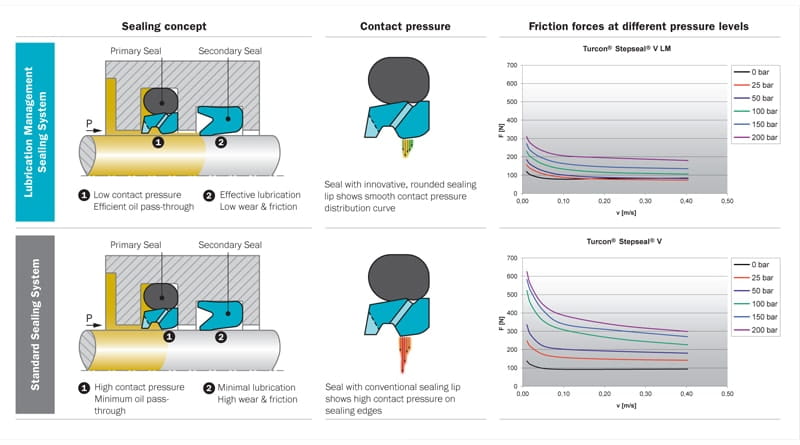

A design study at Hannover Fair in 2015, Lubrication Management systems for fluid power applications, is now in serial production.

Lubrication management is about adjusting lubrication conditions of all single sealing elements within a sealing system so the load on each element can be reduced and the performance in terms of friction-wear-lifetime can be optimized.

Best practice in demanding fluid power sealing applications is a primary and a secondary seal. The primary seal does the sealing job for as long as possible and the secondary seal is the redundancy, there when it is needed. The challenge for this secondary sealing element is length of life under dry running conditions.

Roto KA is Trelleborg’s solution to today’s increasing variation in parameters and the performance limits of conventional rotary shaft seals. Traditionally, circumferential structures are not located on the pressure side. Various past theories have described how rotary shaft seals work and these always assume the sealing mechanism to be in the contact area along with the lubrication. However, the Roto KA design study includes supply and removal channels that are each adapted to the lubrication medium. In a rotating irrigation channel, this allows for the supply and removal of the pressure medium, keeping the oil in motion so it no longer collects in one place.

Through the innovative design of Roto KA, pressure circulation lubrication can be used for the pressure media and its movement can directly and immediately influence the friction speed and the heat generated by the friction. This has a positive effect on the service life of the seal.

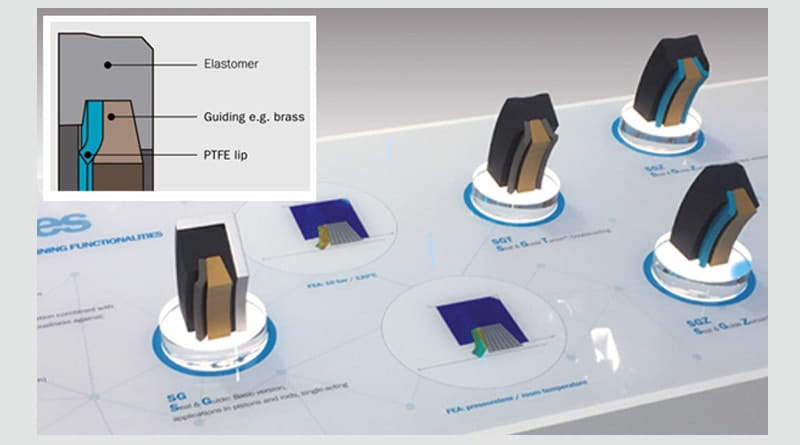

The new Seal and Guide concept brings together sealing and guiding into one seal and guide unit.

By the elastic absorption of the seal and guide part(s), there is a displacement or tension on the guide which is transmitted together with the seal over the elastic absorption of the static seal point. This shifts loads from the more sensitive dynamic sealing edge to the more robust static sealing area. To meet the different requirements of the seal point, the variable selection of material groups is modular.

For example, you can combine elastomer or thermoplastic sealing materials with thermosetting or thermoplastic or even metallic bearing materials as a guide element.

One of the interactive stands at Hannover Fair was about a move Trelleborg Sealing Solutions is making into industry 4.0 and big data. Trelleborg Sealing Solutions has joined the Smart Data Innovation Lab (SDIL) and its first project with the lab is ‘Advanced Condition Monitoring for Sealing Solutions’.

Johannes Kunze von Bischhoffshausen, Manager Digital Transformation and Internet of Things at Trelleborg Sealing Solutions, says: “Industry 4.0 and the internet of things are becoming an important focus for manufacturers worldwide and there is a call for products to become smarter and more intelligent whatever and wherever they may feature.

“SDIL is a great initiative that is easing the journey for component developers and producers to fulfill the objectives of Industry 4.0.”