Trelleborg Showcases Innovations and Expertise at Medical Technology UK 2023

Unique multicomponent parts

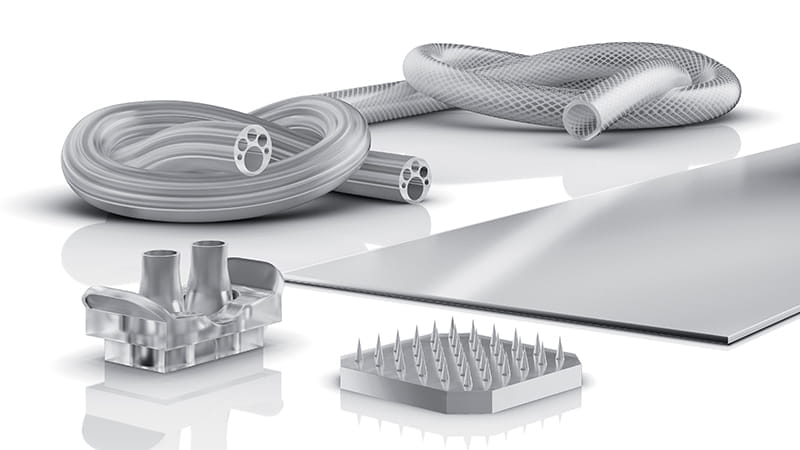

Visitors to stand 73 at the Coventry Building Society Arena can learn about Trelleborg’s multicomponent technology, which pushes the limits of manufacturing innovation to create unique components that no other methods can achieve. Medical equipment manufacturers benefit from a process that helps meet their design goals, including reducing the size and weight of components, while increasing their robustness and improving quality, lowering total cost of ownership.

Trelleborg’s Liquid Silicone Rubber (LSR) experts employ highly sophisticated tools and process engineering to develop novel solutions, combining two, three or more individual materials and components into one fully bonded, robust component. This multi-component injection molding or co-injection – commonly referred to as 2K or 2-shot – produces parts that are more hygienic, eradicating the dead space where bacteria can breed, and lowers costs by cutting out assembly and reducing the number of components in the customer’s supply chain.

>>Find out more about multicomponent technology

Miniaturized wearable and implantable devices

A related technology – micromolding - is critical to the miniaturization of devices so small they are wearable and implantable. Components below 10 milligrams in weight are possible using needlepoint injection technology and fully automated parts handling. Trelleborg’s high dimensional flashless and wasteless design principles create micromolded parts virtually flash-free and not requiring secondary deflashing.

>>Find out more about micromolding and overmolding

“Multicomponent molding can extend design options further than any other technology, enabling device developers the opportunity to go beyond simple function. Virtually boundless product profiles and geometries offer medical device designers options that they may not even be aware of.”

Trelleborg Healthcare & Medical is a leading exponent of moldings used in implantable healthcare and medical devices. Utilizing in-house precision tooling and expertise, Trelleborg creates custom silicone and thermoplastic molded parts with tight tolerances, while satisfying the need for rapid product development with quick turnaround prototypes.

In addition to multicomponent and micromolded parts, Trelleborg will display specialty extruded tubing and hose materials including silicone tubing with unique biocompatibility and physical durability.

>>Find out more about tubing and hose

Also featured are Trelleborg’s drug delivery technologies including drug-eluting silicone with active pharmaceutical ingredients (API), and the Seal-Glide® nanoscale surface treatment. This innovative process improves on the friction performance of conventional solutions yet creates a finish up to 50 times thinner.

>>Find out more about drug-eluting products

>>Find out more about Seal-Glide®

At the adjacent stand 72, Primasil, which is now part of Trelleborg following the October 2022 acquisition of parent company Minnesota Rubber & Plastics, will be showcasing their Medsil range of extruded silicone products and technologies created from custom formulations suitable for harsh environments including low and high temperatures. Medsil products satisfy the most stringent standards demanded by healthcare professionals with materials that are UV, thermally and chemically stable, and hydrophobic, making them easy to sterilize.

>>Find out more about Trelleborg Healthcare and Medical

>>Find out more about Primasil