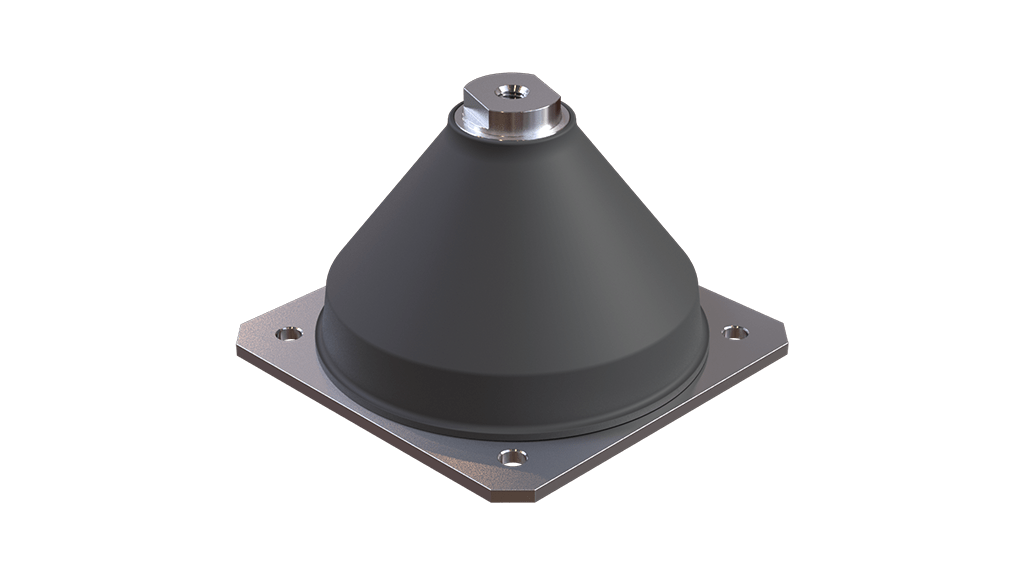

TYPE LO-E1N-3342

| CLASS | STATIC LOAD (KG) | AVERAGE STIFFNESS (N/mm) | PERMISSIVE DEFORMATION (mm) | ||||

| X | Y | Z | X | Y | Z | ||

| 005 | 10-20 | 13 | 13 | 16 | 55 | 55 | 55 |

| 01 | 15-30 | 16 | 16 | 25 | 55 | 55 | 55 |

| 02 | 25-55 | 35 | 35 | 40 | 55 | 55 | 55 |

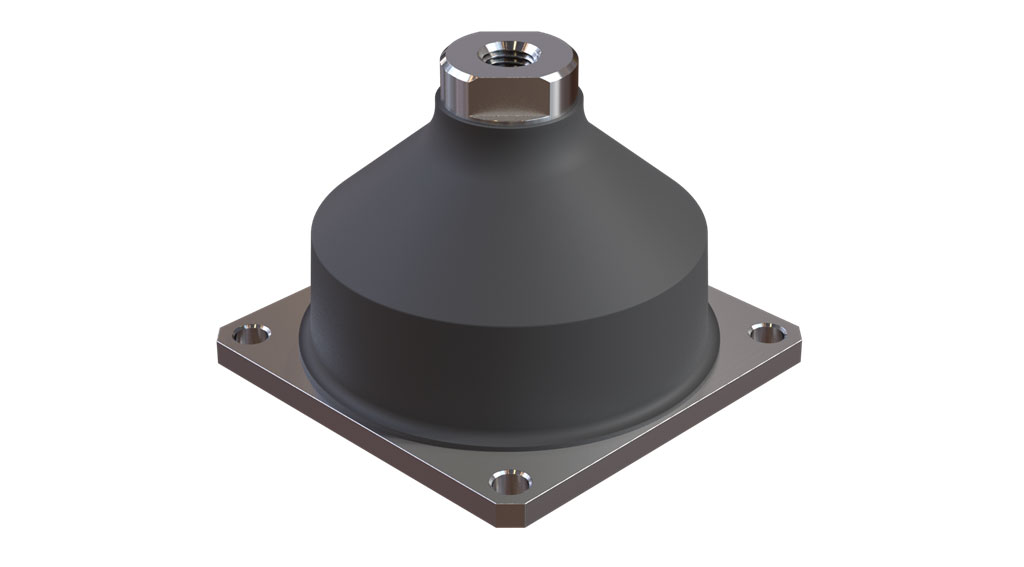

TYPE LO-E1N-3341/DIN 95365-D

| CLASS | STATIC LOAD (KG) | AVERAGE STIFFNESS (N/mm) | PERMISSIVE DEFORMATION (mm) | ||||

| X | Y | Z | X | Y | Z | ||

| 01 | 30-60 | 40 | 40 | 65 | 55 | 55 | 55 |

| 02 | 40-80 | 70 | 70 | 90 | 55 | 55 | 55 |

| 03 | 75-150 | 125 | 125 | 165 | 55 | 55 | 55 |

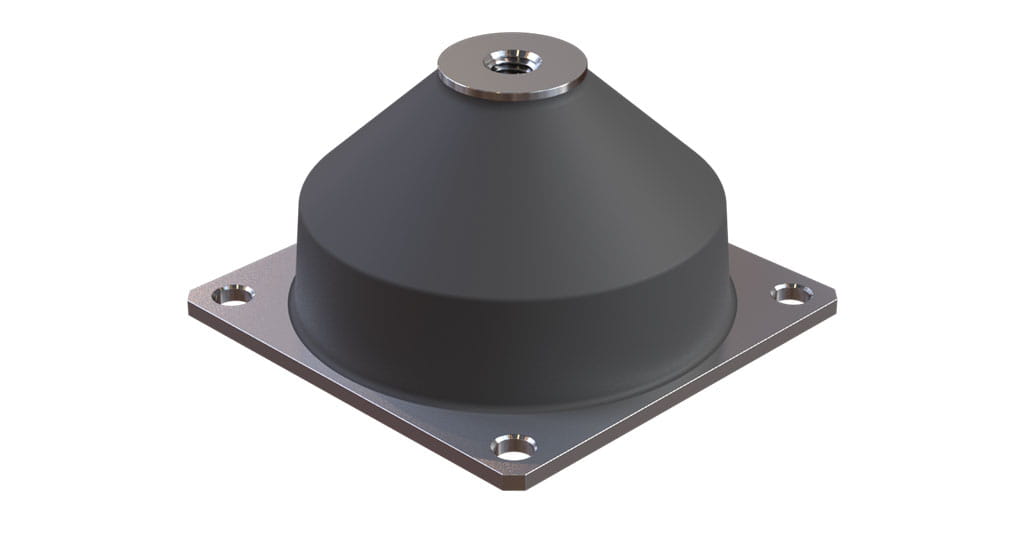

TYPE LO-E1N-3340/DIN 95365-D

| CLASS | STATIC LOAD (KG) | AVERAGE STIFFNESS (N/mm) | PERMISSIVE DEFORMATION (mm) | ||||

| X | Y | Z | X | Y | Z | ||

| 005 | 40-80 | 60 | 60 | 115 | 60 | 60 | 60 |

| 01 | 70-130 | 80 | 80 | 145 | 60 | 60 | 60 |

| 02 | 185-350 | 215 | 215 | 380 | 60 | 60 | 60 |

| 03 | 200-400 | 390 | 390 | 450 | 60 | 60 | 60 |

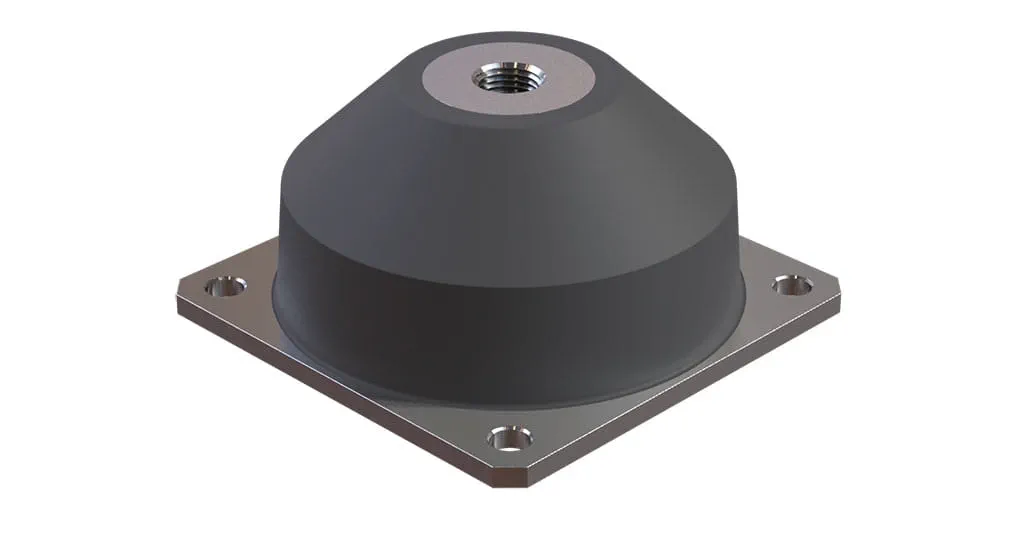

TYPE LO-E1N-2296/DIN 95365-B

| CLASS | STATIC LOAD (KG) | AVERAGE STIFFNESS (N/mm) | PERMISSIVE DEFORMATION (mm) | ||||

| X | Y | Z | X | Y | Z | ||

| S01 | 15-30 | 21 | 21 | 30 | 18 | 18 | 18 |

| S02 | 20-40 | 28 | 28 | 40 | 18 | 18 | 18 |

| S03 | 30-60 | 42 | 42 | 60 | 18 | 18 | 18 |

| 21 | 35-75 | 49 | 49 | 70 | 25 | 25 | 25 |

| 01 | 40-80 | 56 | 56 | 80 | 25 | 25 | 25 |

| 22 | 50-100 | 70 | 70 | 00 | 25 | 25 | 25 |

| 02 | 65-140 | 91 | 91 | 130 | 25 | 25 | 25 |

| 23 | 80-170 | 84 | 84 | 160 | 25 | 25 | 25 |

| 03 | 110-220 | 147 | 147 | 210 | 25 | 25 | 25 |

TYPE LO-E1N-101/DIN 95365-C

| CLASS | STATIC LOAD (KG) | AVERAGE STIFFNESS (N/mm) | PERMISSIVE DEFORMATION (mm) | ||||

| X | Y | Z | X | Y | Z | ||

| 01 | 30-70 | 70 | 70 | 70 | 40 | 40 | 38 |

| 02 | 55-120 | 120 | 120 | 120 | 40 | 40 | 38 |

| 03 | 75-150 | 150 | 150 | 150 | 40 | 40 | 38 |

| 04 | 110-220 | 210 | 210 | 210 | 40 | 40 | 38 |

| 05 | 150-320 | 310 | 310 | 310 | 40 | 40 | 38 |

| 06 | 230-500 | 470 | 470 | 470 | 40 | 40 | 38 |

TYPE LO-E1N-22113

| CLASS | STATIC LOAD (KG) | AVERAGE STIFFNESS (N/mm) | PERMISSIVE DEFORMATION (mm) | ||||

| X | Y | Z | X | Y | Z | ||

| A | 280-650 | 117 | 117 | 57 | 30 | 30 | 35 |

| B | 600-1100 | 228 | 228 | 114 | 30 | 30 | 35 |

| C | 175-350 | 83 | 83 | 40 | 30 | 30 | 35 |

Marine Product Portfolio

The ultimate portfolio containing all data from our range of products for the marine industry.