Dichtungslösungen für die Automobilindustrie

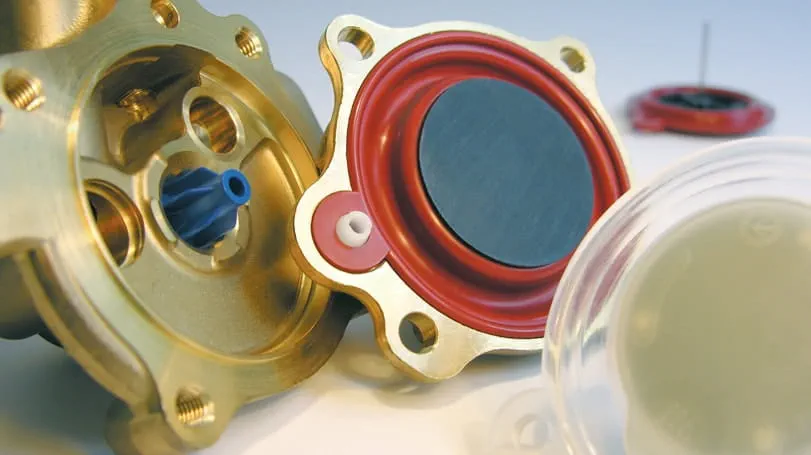

2-Komponenten-Teile

In a proprietary co-injection process, a technical thermoplastic and a silicone are formed into a fully bonded high-precision composite, creating the 2-component part. This fully automated process makes Trelleborg Sealing Solutions a market leader in Liquid Silicone Rubber (LSR) injection molding and 2-shot processing capabilities. If requested, 2-Component parts can be produced in state-of-the-art cleanrooms which offer completely flashless parts for use within safety critical applications.

Automotive trends affecting liquid silicone rubber (LSR) injection molding

- Lighter weight components

- Increasingly sophisticated on-board electronic systems

- Increasing driver safety features

- Increasing driver comfort features

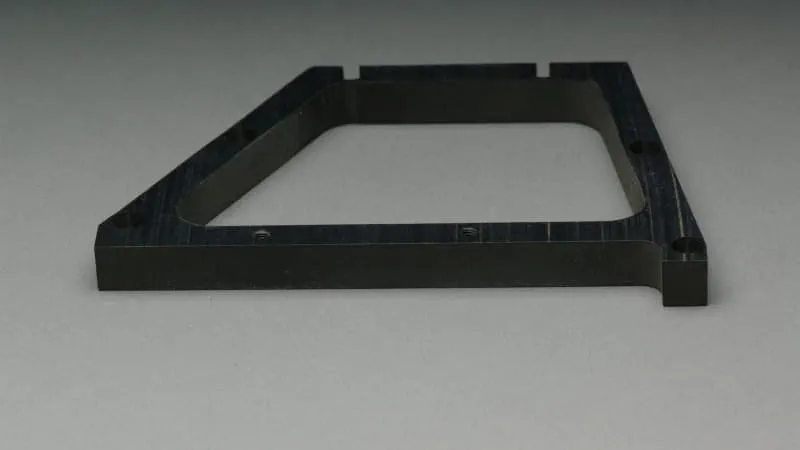

Advanced Composites

Current manufacturing techniques at Trelleborg Sealing Solutions were specifically developed over 30 years ago to help companies overcome the limitations of traditional materials and enable new capabilities for critical parts. Within the automotive sector, many of these parts are already being converted to lightweight fiber-reinforced composites, gaining significant performance benefits while also reducing weight. We are bringing these advantages of automotive composites to unforeseen heights.

With industry-leading expertise in the automated additive manufacturing of thermoplastic composites, we are working with leading manufacturers to create parts for real-world applications that also allow for scalable processing.

Using Automated Fiber Placement (AFP) technology and Trelleborg know-how, we are creating recyclable parts with the lightest weight, greatest fatigue resistance, highest vibration dampening, and best damage tolerance available. By entering the automotive market, we have demonstrated that high-performance parts can be realized even in an industry often requiring high-volume production. In-situ (on-the-fly) manufacturing, high-speed throughput (with our laser heating system), and an additive manufacturing process remove the need for post processing steps. Moreover, we enable residual advantages for the:

- Environment – parts are recyclable and decrease fuel usage

- Consumer – improved mileage and performance

- OEMs – continuous/high throughput manufacturing with new features and material options

Formteile

This may be a flat gasket of any dimension or a seal of complex geometry that may consolidate a number of products into one.

Our specially designed sealing solutions can provide significant benefits from a cost, function, manufacturing or performance perspective, providing you with a real competitive advantage.

Specially Engineered Gasket

ECU housing seals are specially designed to protect electronic components by sealing out transmission oil.

HiSpin® Rotary Seals

Manufactured to meet the needs of electric vehicle manufacturers, HiSpin® rotary seals are specifically engineered for use in next-generation e-axles. A major technology in electric cars, e-axles combine the electric motor and gearbox in a single unit, which poses several unique sealing requirements:

- Conflicting conditions within the e-axle due to the shared housing

- Extreme rotation speeds

- Limited use of lubrication

- Seal material compatibility

HiSpin® rotary seals deliver optimum performance at high rotational speeds under extreme temperature and lubrication conditions:

- HiSpin® HS40

- HiSpin® PDR RT

Learn more about HiSpin® rotary seals for next-generation e-axles

L-Cup®

The FEA optimized design provides outstanding sealing effectiveness and an improved hydrodynamic back pumping effect.

These features are made possible through minimized friction and reduced wear and tear in comparison to traditionally used lip seals.

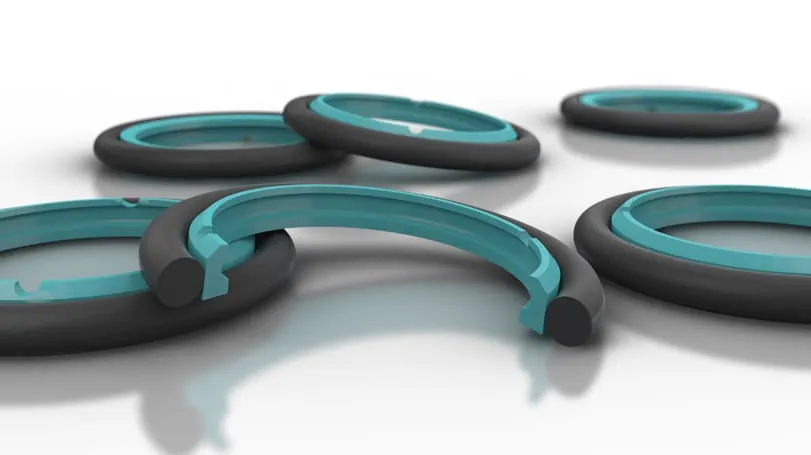

O-Ringe

O-Rings offer the designer an efficient and economical sealing element for a wide range of static and dynamic applications.

The large selection of elastomer materials for both standard and special applications, allow the O-Ring to seal practically all liquid and gaseous media.

Plug-in-Dichtung

Specially developed radial seals that compensate for a wide range of tolerances. Innovative packaging with 3D printing technology is possible and ensures safe transport globally and speed up the manufacturing process in high volume productions.

Application:

Transmission control unit

PTFE-Dichtungen

PTFE based seals are always used if friction, media resistance, and space is an issue. Our Turcon®-PTFE materials, possess a very low friction coefficient and simultaneously a good shape stability against high pressures. They are the ideal materials to design a low friction seal which works with high pressures, minimal space and has a high media resistant. As PTFE does not have an elastomer-elasticity, these kinds of seals are actuated by an O-ring. The O-ring gives the needed elasticity to compensate for misalignment. All of the rod seals have a back pumping effect which enables the seal to bring eventual leakage back to the pressure chamber against the system pressure.

Learn more about some of our patented Turcon Seals

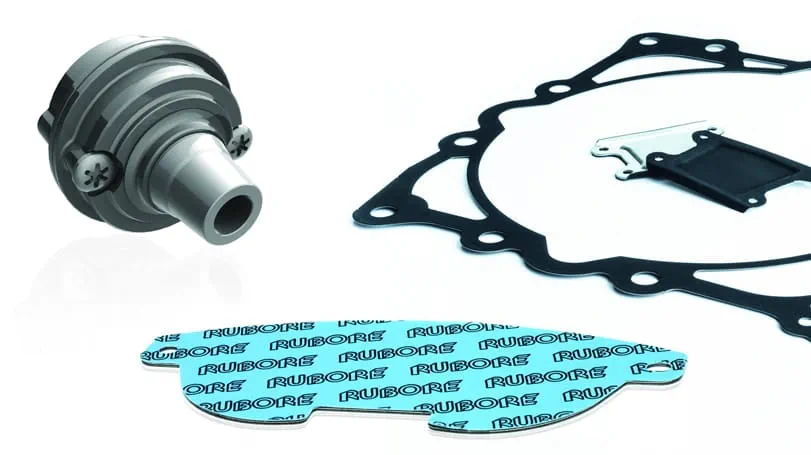

Rubore® Dichtungen

Rubore® Seals are produced through an advanced technology process which creates a sandwich composite material combining rubber, PTFE and metal layers.

Reduces weight:The dimensional stability of Rubore® Seals allows for the design of thinner metal walls which leads to significant weight reductions when compared to full elastomer seals.

Lower handling costs:The stiffness of Rubore® Seals saves assembly time and lessens logistic requirements, lowering overall manufacturing costs.

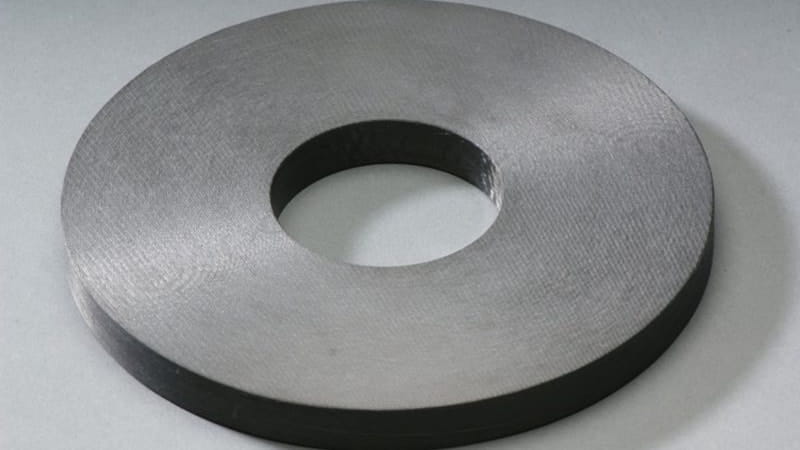

Rubore® Unterlegscheiben

Trelleborg Sealing Solutions Kalmar manufactures a wide range of noise damping shims / insulators that are used when endurance against thermal, chemical and mechanical stress is required. This is combined with out-standing sound damping, sealing, vibration insulation, compressibility and bonding capacity.

The materials consist of different combinations of layers of rubber, carbon steel, stainless steel, fibre glass, cold pressure adhesives, acrylic or silicone based and hot sensitive glues.

Shims / Insulators

Our unique rubber to metal composite materials for noise damping in disc brakes combine a number of valuable properties: vibration insulation, compressibility and excellent adhesion. The rubber composite materials are excellent for applications with demanding insulation for vibration and noise. The materials retain their integrity even when subjected to high pressure and high temperature.

Skirted Piston

Material and Design

Understanding the needs of automotive manufacturers, Trelleborg Sealing Solutions can offer Skirted Piston solutions custom-designed to a wide range of requirements with rapid turnaround times. This includes a size range of 25 to 50 mm and both single or double lip configurations. To note that the metal pistons are to be supplied by the customer, either with an existing groove profile or according to our recommendations.

Turcon® Glyd Ring® T

On areas of low pressure, there is no compression or shear loads on the seal. This, together with the concave shape of the seal, enables a higher radial clearance and reduces the danger of gap extrusion. In addition, the Turcon®Glyd Ring®T provides excellent friction characteristics, no stick-slip and minimal break out force.

Turcon® Roto L

The Turcon® Roto L seal is the first ever active seal and is engineered to extend seal life on axle systems. Uniquely, it only seals when sealing is required. This reduces friction to lower fuel consumption and thereby conserves energy. It is ideal for sealing in drivetrain applications, such as the Central Tire Inflation Systems (CTIS).

Turcon® Roto L combines a PTFE based sealing lip with a rubber jacket and a stable shape-forming metal part. The seal’s patented design ensures that, for the majority of the time, the sealing lip is held lightly against the sealing surface until pressure is activated. This unique design offers features and benefits that no other seal can.

Twin Seal

Highlights

In ride control applications , they are effective in reducing friction and extending seal life,thereby providing a no "stick-slip" effect, maximal performance, superior ride and damping functions.

Ventildichtung

Application:

High pressure fuel pump

Ventseal Light

Sealing Profiles

We provide a wide range of advanced and customized solutions that seal, damp and protect. Our extensive material portfolio makes it possible to be material neutral, offering solutions that provide the exact functionality required. Our range of products includes:

- Extruded seals & gaskets

- Hoses and tubes

- Dampeners

- Protectors

Learn more about our Seals & Profiles

Please note: You will be transferred to the Trelleborg Seals & Profiles website