Fiber Placement

Automated Fiber Placement

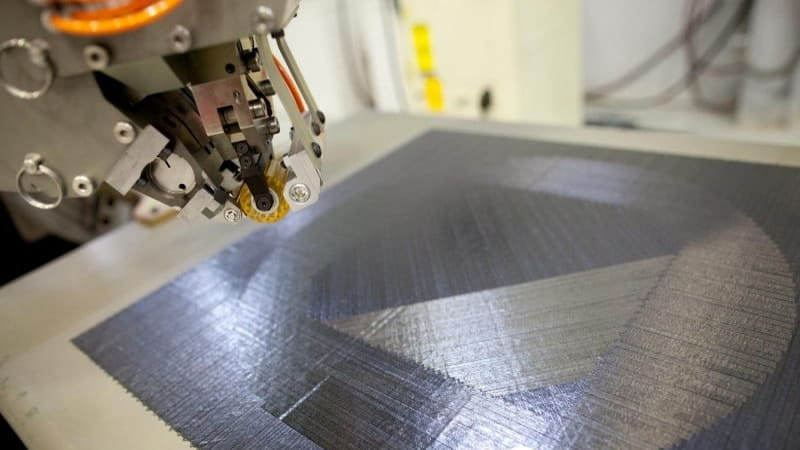

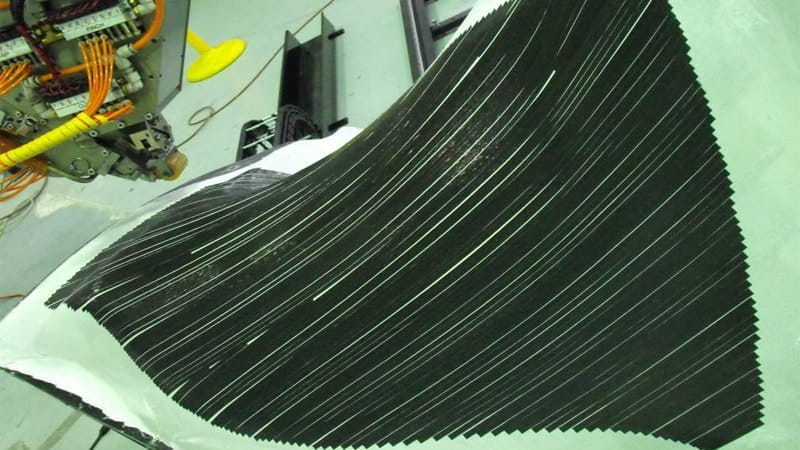

Automated Fiber Placement (AFP) is traditionally used on complex surfaces and smaller structures. We utilize narrow, slit tapes, or “tows,” to make up a given total prepreg band width. In both thermoset and thermoplastic processing, incoming tape is heated through the use of hot nitrogen or a laser. The prepreg materials are applied one ply at a time and consolidated with a compaction roller. Check out the gallery to see our AFP in action!

The need for individual tows or a single wide band should always be a compromise between a part’s surface geometry and the desired manufacturing throughput. Complex geometries that demand complex fiber-placement are typically approached with multiple 0.125 inch – 0.250 inch (3.18 mm – 6.35 mm) tows. While this solution usually conquers the geometry challenge, it can add to machine complexity. A popular middle ground, when possible, is to utilize multiple 0.500 inch (12.77 mm) tapes to improve throughput, while still maintaining good laminate quality on the complex surface. Our Fiber Placement Heads are designed with the total bandwidth in mind. This allows internal material handling components to be tailored to individual tape widths that can sensibly be placed against the part surface as efficiently as possible. We work with you to build a system that fits your projects.

Our Proprietary Thermoplastic Process

Our in-situ thermoplastic process often utilizes only one slit tape, but we still refer to this technology as Fiber Placement. The single tape may be as wide as 2.000 inches (50.80 mm), but we consider this to be narrow for the traditional Tape Laying nomenclature. Typical for thermosetting systems, but unavailable elsewhere for thermoplastic processing, We build multi- 0.250 inch (6.35 mm) tape head systems for both in-situ consolidation and pre-forming applications. We have both single-cut and individual tow control capabilities. Further details can be viewed on our Thermoset AFP or Thermoplastic AFP pages.