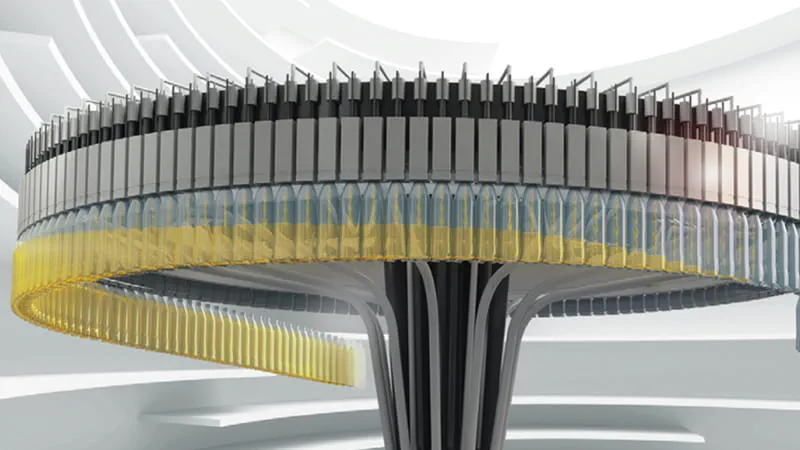

Centrifuge

En fabrikant af centrifuger til medicinindustrien havde behov for store O-ringe til et af deres produkter.

Udfordring:

Tætningerne udsættes for stærke kræfter, hvilket stiller store krav til tætningernes fysiske egenskaber. Herudover skulle tætningerne passe i sporet uden at der opstod tomrum, således at centrifugen nemt kunne rengøres.

Tætningskrav:

- Kompatibel med stærke rengøringsmidler, herunder en del opløsningsmidler

- Overensstemmelse med FDA og USP Class VI standarder

Kaffemaskine

Professionelle kaffemaskiner brygger op til 300 kopper kaffe i timen. Dette stiller køje krav til alle maskinens komponenter, især tætninger.

Udfordring:

Komponenterne i professionelle kaffemaskiner består af metal i modsætning til husholdningsmaskinernes plastik.

Hårde overflader kombineret med kaffebønners slibende egenskaber betyder at tætninger slides hurtigt. En førende producent af professionelle kaffemaskiner arbejdede sammen med Trelleborg Sealing Solutions for at maksimere tætningernes levetid. Målet var at opnå 100.000 cykler før før udskiftning var nødvendig.

Filling machines

Filling machines have numerous filling heads activated by pistons.

Sealing issue:

A filling machine manufacturer discovered fruit particles were being trapped in elastomer seals used within their filling heads. This led to contamination, which was difficult to clean out due to seal design. In addition, the elastomers were sticking to the piston shaft, impeding piston motion and making filling erratic.

Sealing requirements:

- High chemical resistance

- Withstand CIP chemicals and operate in steam up to 150°C / 302°F

- Compliant with FDA and USP Class VI standards

Solution:

Trelleborg Sealing Solutions recommended replacing the elastomer seal with a Turcon® Variseal® Hi-Clean. As it fitted into the existing O-Ring groove, no equipment redesign was necessary. The stainless steel spring that energizes the seal is encased in silicone. This means that it is easily cleaned and sterilized with no risk of contamination. The low friction characteristics of the Turcon® PTFE based material prevents sticking, even after extended periods of rest. The grade of Turcon® MF material chosen was also compliant to all relevant approvals.

Result:

In application, the Turcon® Variseal® Hi-Clean eliminated all risk of contamination. In addition filling action was improved due to the low friction characteristics of the seal.

More information on Turcon® MF

Find out about Turcon® Variseal® Hi-Clean

Flangetætninger

I et moderne forarbejdningsanlæg findes tusindvis af rør som er koblet sammen. Disse sammenkoblinger er tætnet med Flangetætninger og O-ringe. Selv om prisen på hver enkelt af disse tætninger er minimal, kan vedligeholdelsesomkostningerne blive meget høje.

Udfordring:

Flangetætninger som tætner rørsamlinger i forarbejdningsanlæg er i konstant kontakt med systemets medier og udsættes for aggresive rengøringsmetoder. Et multinationalt medicinalfirma oplevede at deres tætninger i et sådant system forringedes hurtigt. Vores kunde ønskede at reducere vedligeholdelsesomkostningerne ved at forlænge intervallerne mellem vedligeholdelseseftersyn. Dette måtte ikke gå udover tætningernes integritet, da enhver form for forurening ville medføre store omkostninger i form af kasserede produkter.

Blandingssikrede ventiler

Blandingssikrede ventiler er nøglekomponenter i automatiserede forarbejdningsanlæg. Anlæggene bruges til fremstilling af mange produkter, fra fødevarer til medicin og kosmetik. Blandingssikrede ventiler muliggør sideløbende forarbejdning og rensning af systemet, samtidig med at blanding af medier forhindres.

Udfordring:

Trelleborg Sealing Solutions blev kontaktet af en førende ventilfabrikant for at bistå med udvikling af tætningskonfigurationen til en ny generation af ventiler. Ventilerne skulle operere 24 timer i døgnet, og tætningerne ville derfor blive udsat for angreb fra højkoncentrerede CIP-medier og overhedet damp. Derudover skulle flere af tætningerne anvendes dynamisk.

Quick couplings

Quick couplings are now extensively used in process lines to allow for a flexible production system and to make maintenance and repair quicker and easier.

Sealing issue:

A leading quick coupling manufacturer wanted to develop a coupling for use in the chemical and beverage industry. The elastomer seals that they usually fitted in their product would not stand up to the harsh conditions of these processing lines. They approached Trelleborg Sealing Solutions for a solution that would be chemical and steam resistant while complying with relevant industry standards.

Sealing requirements:

- High chemical resistance

- Withstand CIP chemicals and operate in superheated steam.

- Compliant with FDA and USP Class VI standards

- Tight tolerances

Solution:

Depending on cleaning regimes and process media, Trelleborg Sealing Solutions recommended O-Rings in either EPDM or Isolast®.

Result:

By using seals in these materials, quick couplings could be effectively cleaned and sterilized without causing deterioration of the O-Rings. This meant that the customers of the coupling manufacturer benefited from long component life.

Find out about Isolast®

Safety valves

Safety valves are installed to protect critical equipment.

Sealing issue:

A major medical equipment manufacturer had an existing design of safety valve. The seal was contained within a three-piece assembly. The manufacturer wanted to increase the chemical resistance of the sealing element by specifying a FFKM material. Trelleborg Sealing Solutions believed by value engineering the complete assembly they could offer the customer a cost-effective sealing component that would improve integrity.

Sealing requirements:

- High chemical resistance

- Withstand CIP chemicals and operate in steam up to 150°C / 302°F

- Compliant with FDA and USP Class VI standards

Solution:

With unique bonding technology, we were able to bond our Isolast® material to metal. This allowed the three separate components of the assembly to be produced as one item.

Result:

The resulting design of sealing element proved to be highly cost effective. Total cost was reduced by extending replacement intervals, a reduction in the amount of sealing material required and lower assembly costs. The component proved highly effective and the same concept is being used across their product range.

Find out about Isolast®

Tank spray systems

Spraying systems are incorporated into tanks to clean them. Generally the spray head is now retracted automatically from the tank.

Sealing issue:

Trelleborg Sealing Solutions worked with a manufacturer who was developing a unique retractable spray ball system. It operates pneumatically which allows it to have the major benefit of being self-draining. A complete sealing configuration was required which could operate with liquid on the one side and air on the other. Under pressure from both sides and at high temperature, seals in contact with cleaning media had to withstand the harsh chemicals used in these regimes.

Sealing requirements:

- High chemical resistance

- Chemically resistant to all types of CIP media

- Compliant with FDA and USP Class VI standards

Solution:

Trelleborg Sealing Solutions recommended a configuration of seals including a Turcon® Variseal®, along with O-Rings in EPDM and Isolast® options depending on chemical resistance requirement. The surface of the elastomer O-Ring at the neck of the spray ball was treated with FDA compliant FF coating. This gave the seal the necessary friction characteristics to allow smooth dynamic operation of the spray head.

Result:

The seal configuration withstood extensive tests. After cycles of 1,000 operations, there was no leakage and pressure was held. The seals also continued to perform after a temperature test where the units were heated up to 140°C / 284°F for 24 hours.

More information on EPDM

Find out about Isolast®