The FlatSeal™ HMF30 series of graphite based flat gaskets has been specially engineered for use in extreme operating environments. Each material consists of a high-performance graphite foil, which can be combined with a metal layer or layers and XP Technology, giving each material its own unique performance profile.

Features and benefits

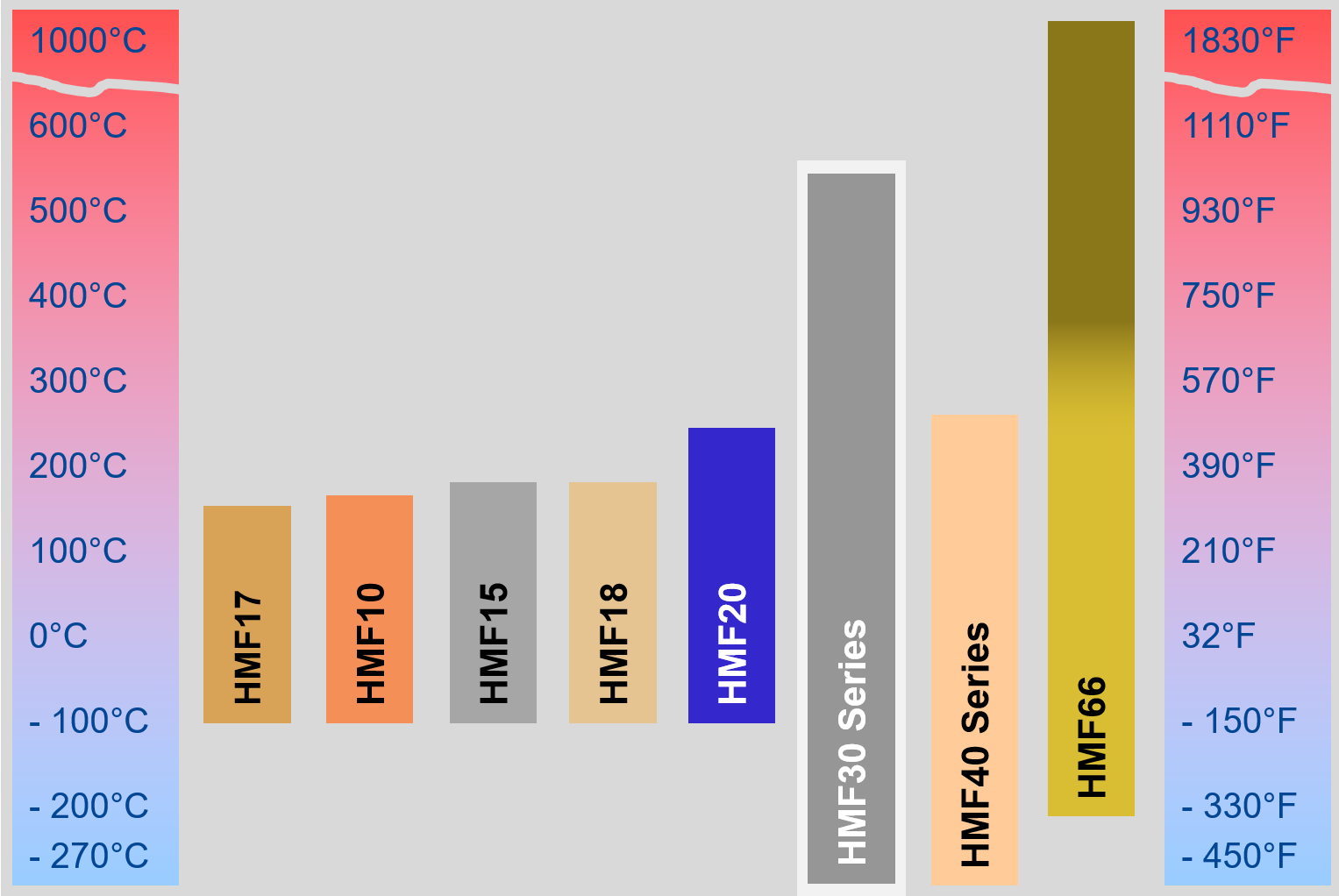

- Suitable for temperatures from -200 °C to +550 °C / -364 °F to +1022 °F

- Retains sealing performance with changing loads

- Maximum adaptability to flange unevenness

- Extreme low creep in high temperature applications

- Universal chemical compatibility

- XP Technology maximizes oxidation resistance and minimizes downtime for maintenance

- Meets TA Luft (Technical Instructions on Air Quality Control) fugitive emissions requirements

- Suitable for designs that must comply with VDI (Verein Deutscher Ingenieure, German Association of Engineers) guideline 2290

FlatSeal™ HMF30 and HMF32 - Versatile graphite gaskets

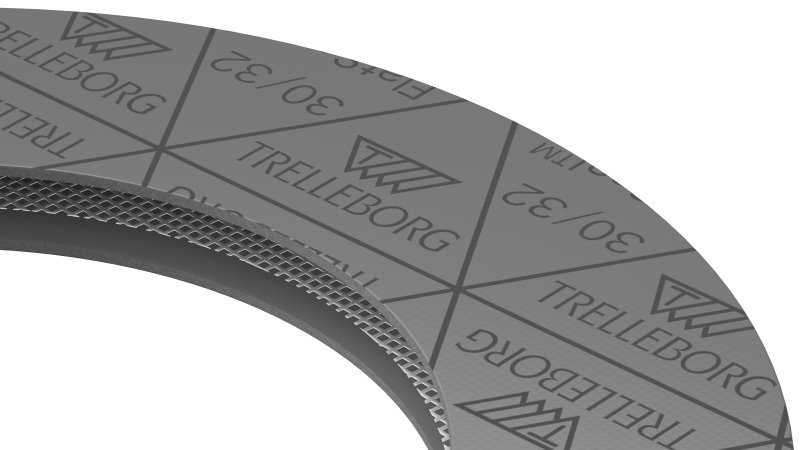

FlatSeal™ HMF30

Reinforced with an expanded metal layer, FlatSeal™ HMF30 suitable for a wide range of uses, which optimizes logistics and handling processes.

FlatSeal™ HMF32

FlatSeal™ HMF32 (blue printing) combines the characteristics of FlatSeal™ HMF30 with innovative XP Technology. This makes graphite more resistant to oxidation for extended sealing performance and significantly reduces graphite deposits on sealing surfaces, facilitating maintenance processes.

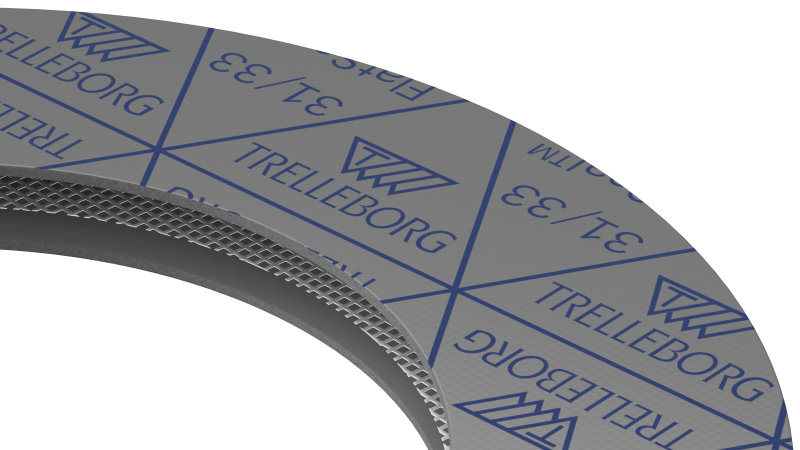

FlatSeal™ HMF31 and HMF33 - Optimized sealing performance to meet fugitive emissions requirements

FlatSeal™ HMF31

FlatSeal™ HMF31 is an excellent all-round standard gasket, ideal for a broad range of processing applications.

FlatSeal™ HMF33

Enhanced with XP Technology, FlatSeal™ HMF33 (blue printing) offers superior leakage performance with maximum oxidation resistance to extend gasket life and features anti-stick properties, simplifying gasket replacement processes.

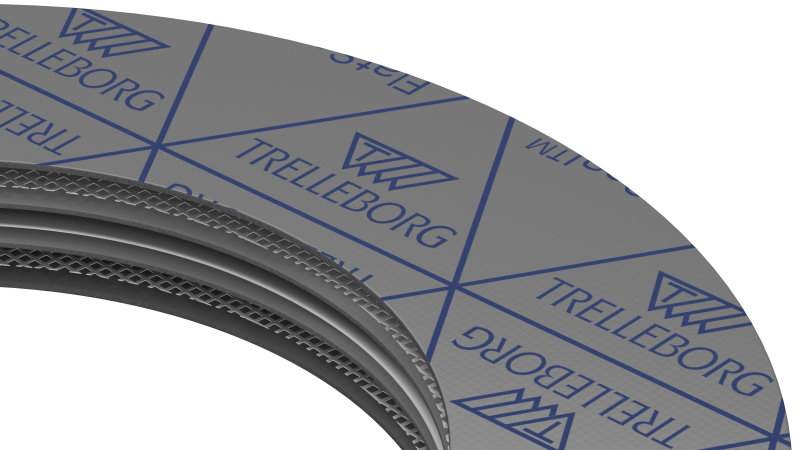

FlatSeal™ HMF36 - Unique multilayer structure for superior performance

With its innovative multilayer concept, FlatSealTM HMF36 offers outstanding adaptability to flange surfaces and the highest mechanical stability. It is made from expanded graphite foil reinforced with a combination of expanded and smooth metal layers.

This high-performance flat gasket is suitable for use in operating environments with extremely high pressures and temperatures and can withstand changing loads. It meets TA Luft fugitive emissions requirements and can be used in designs that must comply with VDI guideline 2290.

FlatSealTM HMF36 is equipped with XP Technology, which extends service life and simplifies maintenance operations.

FlatSeal™ HMF38 - For complex gasket geometries

Specially engineered for filigree and complex geometries and thin gasket thicknesses, FlatSealTM HMF38 is composed of expanded graphite foil, reinforced with a smooth metal layer.

Compared to conventional tanged metal gaskets, it offers the following benefits:

- Enables gaskets with thicknesses under one millimeter

- Facilitates complex geometries with narrow gaskets widths

- Eliminates contact corrosion at the flange surfaces due to projecting metal

This unique performance profile makes FlatSealTM HMF38 ideal for numerous OEM and processing industry applications, including fittings, compressors, pumps and valves.