Our advanced sealing technology enhances the efficiency and reliability of green hydrogen systems, enabling the widespread adoption of this clean energy source and accelerating the transition to a more sustainable future.

Green hydrogen, produced through renewable energy-powered electrolysis, finds diverse applications:

- Energy storage medium, balancing intermittent renewables

- Hydrogen fuel cells utilize it for clean transportation

- Industries adopt it for ammonia production, steel manufacturing, and chemical synthesis

- Power generation through hydrogen in gas turbines offers low-carbon electricity

- Green hydrogen replaces natural gas for heating and cooling

- Hydrogen refueling stations, aiding the expansion of fuel cell vehicles

- Convert hydrogen into carriers like ammonia for long-distance export

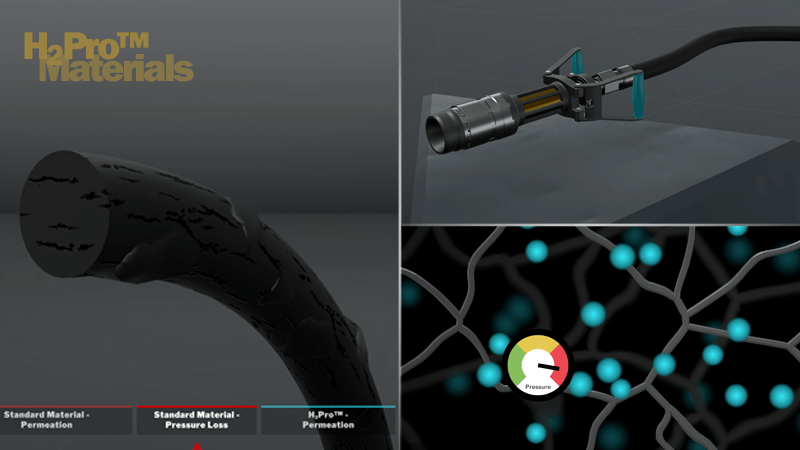

Sealing technology for green hydrogen end-use applications is essential for ensuring the integrity and safety of hydrogen systems. Whether it's in fuel cells, hydrogen storage, or transportation, reliable seals are crucial to prevent leakage and maintain optimal performance. Seals for green hydrogen end-use must exhibit high chemical resistance, withstand extreme temperatures and pressures, and effectively contain hydrogen gas. Advanced sealing materials, such as specialized elastomers and engineered plastics, are employed to meet these demanding requirements.

Hydrogen Turbine

Natural gas turbines can be transitioned to blended hydrogen-natural gas turbines to generate electricity. These innovations are designed to phase out natural gas altogether. Components within turbines must be able to withstand high temperatures and be compatible with various gas mixtures and resist rapid gas decompression

Products

- Wills Rings® metal seals

- Turcon® Variseal® H and Turcon® Variseal® HF

- Custom engineered plastic bearings

Internal Combustion Engine

When hydrogen is used as a fuel in vehicles with an internal combustion engine, seals must be able to operate in a wide temperature range -40 °C-+85 °C/-40 °F-+185 °F under high pressures, up to 40 bar/580 psi and prevent leakage to ensure passenger safety.

Products

- Multicomponent parts

- Static seals

- Rubber-to-metal bonded gaskets

Fuel Cells

Fuel cell applications are especially challenging for seals, since they operate at a wide temperature range -253 °C-+85 °C/-423 °F-+185 °F and there is a significant risk of electrochemical attack, which can damage sealing materials and hardware.

Products

- Rubber-to-metal bonded gaskets

- HMF FlatSealTM flat gaskets and frame gaskets

- O-Rings

>> Learn more about our solutions for fuel cell electric vehicles (FCEV)