Optimizing application function through specialist materials

From materials that perform in extreme temperatures or pressures, to compounds that resist challenging chemicals or meet stringent approvals, Trelleborg Healthcare & Medical offers a range of elastomer materials to optimize the function of a wide variety of pharmaceutical, biotech, medical and life science applications.

Tackle MDR requirements with your supplier’s material expertise

EPDM

Superior resistance to polar chemicals

Quick Facts

- Operating temperatures from -45 °C to +160 °C / -49 °F to +320 °F

- Special grades up to +200 °C / +392 °F

- Exceptional mechanical performance

- Low long term compression set with specific compounds

- Minimal risk of contamination from leach out of softeners and process aids

- Long life in polar solvents, hot water and steam

- Suitable for contact with alkaline cleaning fluids

- Tested in accordance with ASTM, BfR, SIS and FDA

- High wear resistance, minimal creep and permeation

- Compliances with FDA CFR177.2600, 3-A, USP Class VI, Cytotoxicity (USP 87), NSF, KTW, WRAS etc

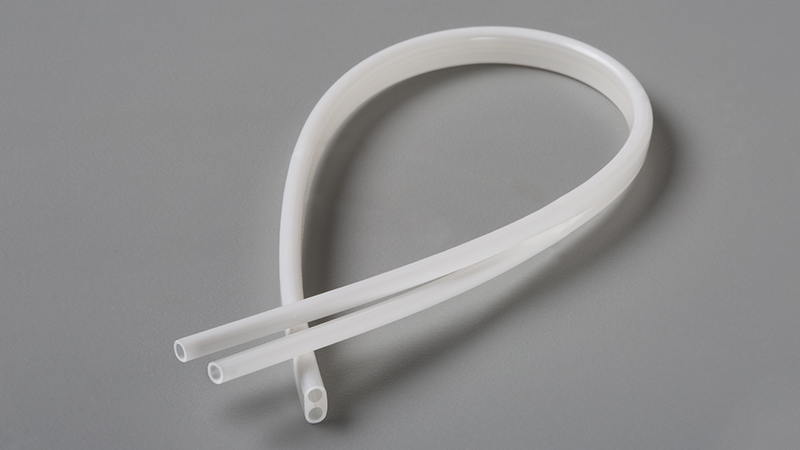

Typical Healthcare & Medical Applications: Universal material used in a wide variety of applications, filling, dispensing, pumps, pipes and flange gaskets, valves, quick connectors, tanks, separators, homogenizers, decanters and heat exchangers.

Products Available: O-Rings, Kantseal, Flatseal, Gaskets, Diaphragms, bonded seals and custom components.

About EPDM

Ethylene Propylene Diene Rubber (EPDM) polymers are fully saturated, non-polar hydrocarbon based elastomers. Their polymer geometry gives them superior compatibility with polar fluids and polar solvents at elevated temperatures. The materials have high chemical resistance, giving long life in polar solvents, hot water and steam. In addition, they are suitable for contact with alkaline cleaning fluids.

All EPDM grades are peroxide cured and contain a very low amount of softeners and process aids. This reduces potential leach out to a minimum, lowering the risk of contamination. They have also been engineered to achieve enhanced chemical and thermal stability along with compliance to a variety of healthcare and medical standards and approvals.

Isolast

Unrivalled chemical and thermal resistance

Quick Facts

- Temperature resistance from -25 °C to +325 °C / -13 °F to +617 °F

- Combines the advantages of an elastomer with the chemical resistance of a PTFE

- Almost universal chemical compatibility

- Materials perform well in a broad range of chemical media including ethylene oxides, acids, alkalis, amines, esters and steam

- Exceptional hysteresis properties

- Outstanding low long-term compression set characteristics

- High purity, low contamination from extractables

- Complete traceability

- Reduce downtime and improve production efficiency

- Sealing effectively under pressure or in a vacuum

- Materials compliant to FDA 21 CFR.2400 (d), 3-A, USP Class VI, Cytotoxicity (USP 87)

Typical Healthcare & Medical Applications: Universal material used in a wide variety of applications that require outstanding performance. Ideal for process systems requiring intensive CIP and SIP regimes or aggressive process media.

Products Available: Wide variety of standard and custom designs, O-Rings.

About FFKM

Isolast® is the Trelleborg Healthcare & Medical range of high specification perfluoroelastomer (FFKM) compounds. We offer the widest portfolio on the market engineered to meet specific processing demands. Virtually inert, the materials perform well in a broad range of media including organic and inorganic oxides, acids, alkalis, amines, esters and steam at continuous operating temperatures from -25 °C to +325 °C / -13 °F to +617 °F.

Unrivalled Operating Characteristics

FFKM materials are terpolymers of monomers in which all hydrogen atoms have been replaced by fluorine. The absence of hydrogen in their molecular chain dramatically increases both their chemical and thermal resistance. The cross-linked molecular chains enable them to combine the resilience and sealing force of an elastomer with the chemical inertness and thermal stability of PTFE.

Literature:

FKM

Engineered to specific life sciences criteria

Quick Facts

- Temperature resistance from -20 °C to +220 °C / -4 °F to +428 °F

- Steamable FKM up to +170 °C / +338 °F

- Very good chemical compatibility and resistance

- Good compatibility with acidic fluids, fatty food products, food grade lubricants and oils

- Low total organic carbon and metal extractables

- Low long-term compression set characteristics

- Material compliant to FDA 21 CFR177.2600, 3-A, USP Class VI, Cytotoxicity (USP 87)

Typical Healthcare & Medical Applications: Mechanical seals, decanters, separators, pumps, tanks, valves, heat exchangers and equipment cleaned using clean-in-place and sterilize-in-place regimes.

Products Available: O-Rings, square seal, Kantseal, Flatseal™, gaskets, diaphragms, also reinforced. FKM can be bonded to other materials and delivered as engineered parts in almost any design.

About FKM

Trelleborg Healthcare & Medical has optimized the performance of our Fluoroelastomer (FKM) material range, engineering it to meet the specific criteria of the life sciences industry. Materials demonstrate good elevated temperature characteristics and compatibility to media used in cleaning regimes.

Nitrile

FDA and 3-A compliant

Quick Facts

- Temperature resistance from -30 °C to +100 °C / -22 °F to +212 °F

- Up to +120 °C / +248 °F for short periods

- Special formulations down to -60 °C / -76 °F

- Good mechanical properties

- Good resistance to hydrocarbons of high aromatic content and water

- Compliant to FDA CFR177.2600 and 3-A

Typical Healthcare & Medical Applications: Patient lifts, prosthetic knees and ankles, anti-vibration applications.

Products Available: O-Rings, gaskets, diaphragms

About NBR and HNBR

Acrylonitrile-Butadiene Rubber (NBR) is a good choice for applications where seals will not be exposed to harsh cleaning regimes, ozone or superheated steam. These materials are copolymers of butadiene and acrylonitrile. The percentage of these in the NBR and HNBR formulations determines their performance characteristics.