Key Benefits:

- Excellent chemical compatibility

- Lowest coefficient of friction material

- Possible to alter properties with additives

- Provides barrier resistance

Typical Healthcare & Medical Applications:

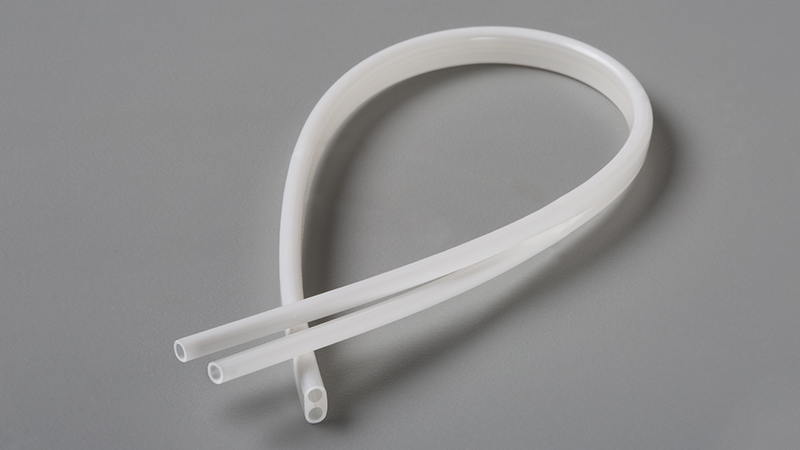

Custom PTFE shaped components are used in many medical applications. Typical areas include diagnostic instrument pumps and valves, oxygen concentrators and fluid transfer applications.

About PTFE Custom Shapes

Trelleborg Healthcare & Medical develops PTFE compounds, modifying its basic properties with a variety of additives. The material is compressed and sintered at about +371 °C / +700 °F. Once the PTFE is sintered, it can be processed into a variety of custom shapes such as bellows or diaphragms, thermoformed or machined into any shape. Trelleborg Healthcare & Medical can also over-mold to PTFE to create custom shapes for applications requiring both chemical resistance and a sealing function.