Advantages of 2C LSR Technology:

- Offers designers much more latitude in design solutions

- Can integrate multiple components into one fully-bonded solution

- Single component is more robust than an assembly of individual parts

- Provides lighter weight components

- Risks and costs associated with secondary assembly can be avoided

- Lowers cost by reducing the number of components in the customer’s supply chain

- Increases cleanliness and hygiene by eliminating dead space and potential bacteria growth in the finished product

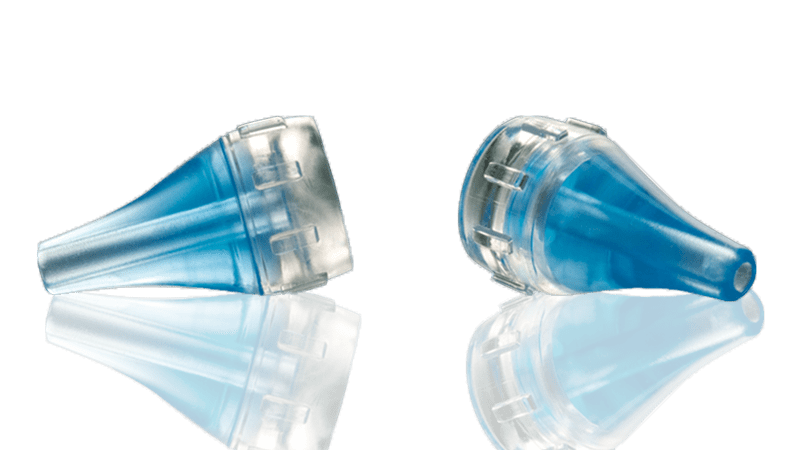

Enhanced processing options for more hygienic designs

Trelleborg Healthcare & Medical is at the forefront of tool, process and automation technology for 2C or two shot liquid injection molding. In a fully automated and closed loop system, either a combination of thermoplastic and liquid silicone or two dissimilar grades of liquid silicone are co-molded into a bonded component that offers a wealth of benefits in both assembly and function of the finished product.

A second process option for two component parts, suited for lower production runs and commonly applied by Trelleborg Healthcare & Medical is overmolding. Here, Liquid Silicone Rubber is injected over either a thermoplastic or metal component to create a fully bonded part.