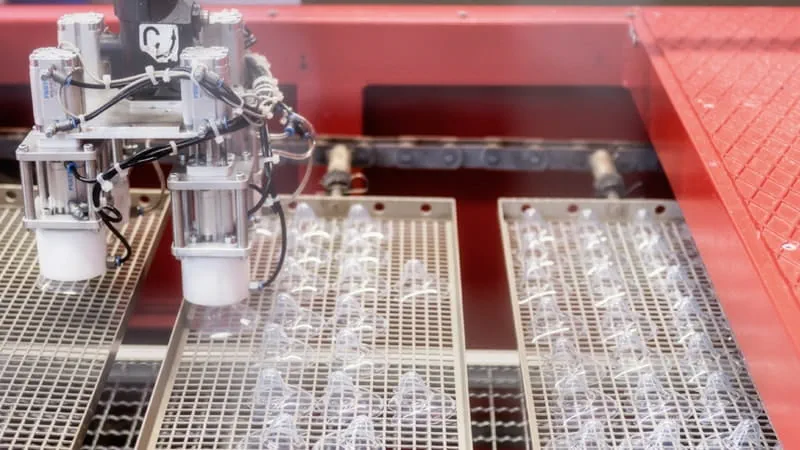

Automated Manufacturing of Silicone Components for High quality, cost-effective solutions

Our fully automated manufacturing process aims to provide customers with high quality, pure and cost effective solutions. We combine expertise in tool design and process engineering with the highest levels of process automation, in particular for:

- Liquid Silicone Injection Molding (LIM)

- Two Component Injection Molding

Our fully automated LSR and LIM processing provides all the advantages needed for success in the healthcare and medical industry:

- Purity – a closed loop system ensures that no external impurities can be introduced through either the process or human contact

- Precision – flashless, wasteless tool design concepts ensure high precision and quality

- Quality – quality is controlled in the process, not through extra control steps

- Reliability – automation guarantees repeatability and reliability of process across millions of parts produced every year

- Cleanliness – closed loop manufacturing set-ups in Class 7 and 8 cleanrooms guarantee the highest level of cleanliness

- Cost Effectiveness – Lowest Total Cost of Ownership (TCO)