The FlatSeal™ HMF40 series is a range of polytetrafluoroethylene (PTFE) based flat gaskets, specially engineered for superior sealing performance with the widest range of media. The innovative mix of PTFE and special functional fillers gives each gasket material a unique performance profile. Alongside chemical compatibility, HMF40 materials are suitable for use in operating environments with very low to high temperatures and extreme pressures.

Features and benefits

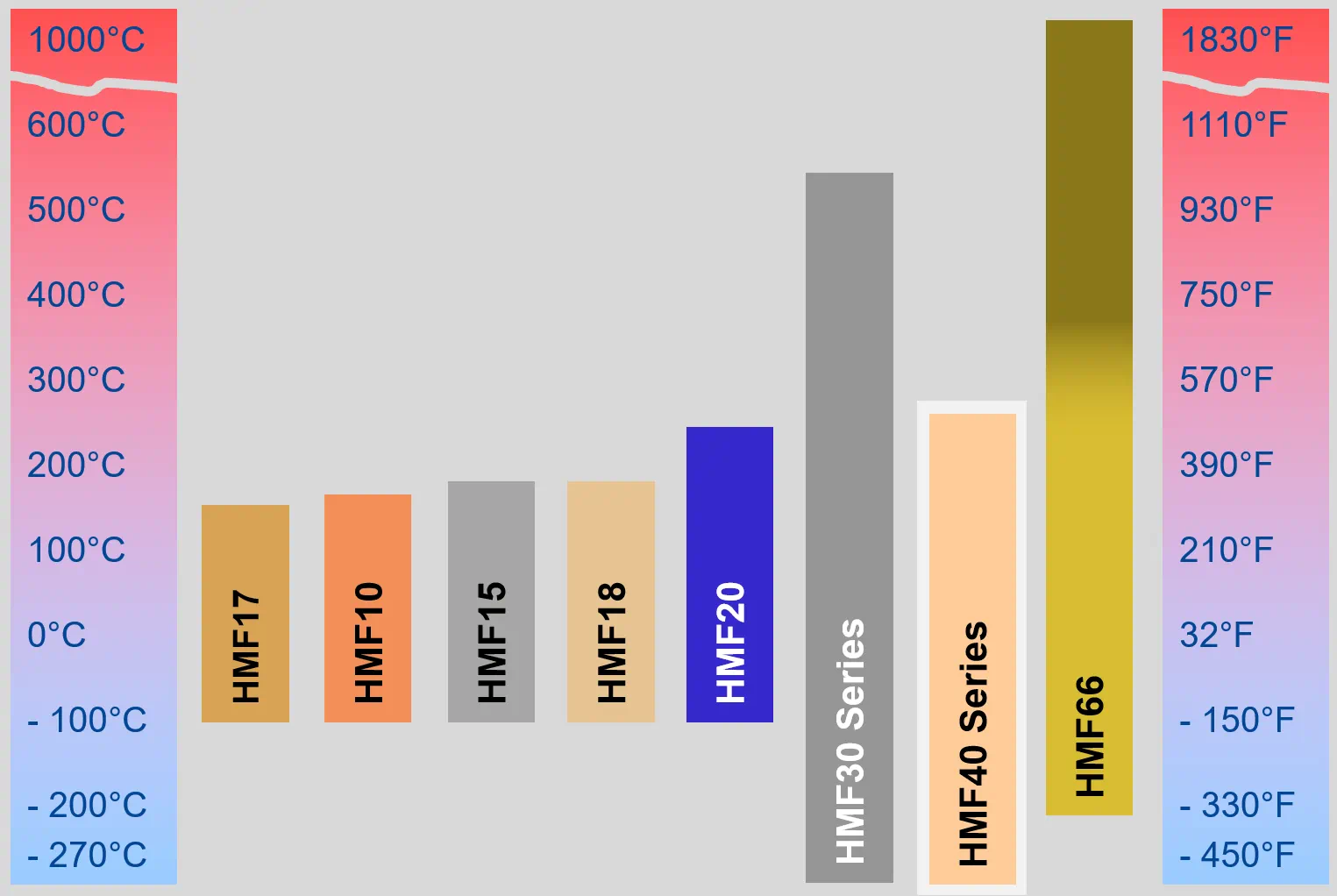

- Suitable for operating environments with temperatures from -270°C / -454 °F to +260°C / +500 °F

- Compatible with the widest range of media including aggressive acids, alkalis and solvents

- Satisfies leakage limits specified in DIN 3535-6

- Blowout resistant

- Excellent low creep properties

- Unlimited shelf life

- Meets TA Luft (Technical Instructions on Air Quality Control) requirements

- Compliant with food contact material regulations FDA CFR 21 § 177.1550, EC 1935/2004 and Chinese GB

FlatSeal™ HMF41 - Enhanced flexibility for stress sensitive flanges

The innovative combination of modified PTFE and hollow glass microspheres, makes FlatSeal™ HMF41 uniquely flexible, giving it the ability to adapt to flange surfaces. This facilitates effective sealing performance on uneven or moderately damaged surfaces and makes it suitable for applications sensitive to stress, such as glass, ceramic and fiber reinforced plastic (FRP) flanges.

Demonstrating outstanding media resistance, FlatSeal™ HMF41 is ideal for use in the chemical industry, including processing equipment and chemical transportation applications, such as tank cars.

Advantages: Flexible material – Ideal for chemical transportation applications

Demonstrating outstanding media resistance, FlatSeal™ HMF41 is ideal for use in the chemical industry, including processing equipment and chemical transportation applications, such as tank cars.

Advantages: Flexible material – Ideal for chemical transportation applications

FlatSeal™ HMF42 - High mechanical strength for aggressive alkalis

Due to its special blend of modified PTFE and barium sulphate, FlatSeal™ HMF42 offers superior sealing performance in applications containing harsh alkalis. The high purity material demonstrates excellent low creep properties, high mechanical strength and the ability to withstand pressures, ranging from vacuum to 83 bar / 1204 psi.

The high purity of the gasket material makes HMF42 the ideal solution for the food processing and pharmaceutical industries.

Advantages: Very robust – Compatible with strong alkalis – High purity properties

The high purity of the gasket material makes HMF42 the ideal solution for the food processing and pharmaceutical industries.

Advantages: Very robust – Compatible with strong alkalis – High purity properties

FlatSeal™ HMF43 - Robust gasket for high temperature applications

FlatSeal™ HMF43 combines superior chemical compatibility with excellent low creep properties, making it ideal for use in a wide range of applications in the chemical and petrochemical industries.

The combination of modified PTFE and silica gives the flat gasket high mechanical strength, making it able to withstand a wide range of temperatures and pressures, from vacuum to 83 bar / 1204 psi. In addition, it is uniquely compatible with concentrated acids, except for hydrofluorides.

Advantages: Excellent all-around solution – Withstands high temperatures - Compatible with aggressive acids

The combination of modified PTFE and silica gives the flat gasket high mechanical strength, making it able to withstand a wide range of temperatures and pressures, from vacuum to 83 bar / 1204 psi. In addition, it is uniquely compatible with concentrated acids, except for hydrofluorides.

Advantages: Excellent all-around solution – Withstands high temperatures - Compatible with aggressive acids

FlatSeal™ HMF45 – Expanded PTFE offers unique properties

Utilizing advanced processing technology, FlatSeal™ HMF45 is made using high purity, multidirectional, expanded PTFE. During the expansion process, the structure of the PTFE material becomes highly cross-linked and oriented in many directions, resulting in a robust material with high compression properties, which provide good adaptability to flange unevenness.

FlatSeal™ HMF45 is suitable for use in with a wide range of chemicals, both acidic and alkaline, and can withstand high pressure environments up to 100 bar / 1450 psi. This makes it suitable for glass lined flanges, FRP equipment and in pipework and reactors in the processing industry.

Advantages: Unique, expanded PTFE - Outstanding flexibility – Suitable for high pressure environments

FlatSeal™ HMF45 is suitable for use in with a wide range of chemicals, both acidic and alkaline, and can withstand high pressure environments up to 100 bar / 1450 psi. This makes it suitable for glass lined flanges, FRP equipment and in pipework and reactors in the processing industry.

Advantages: Unique, expanded PTFE - Outstanding flexibility – Suitable for high pressure environments

FlatSeal™ HMF48 - Suitable for universal use in food contact applications

Specially engineered to meet the unique requirements of the food and beverage processing industry, FoodPro® HMF48 is formulated from virgin PTFE and enhanced with high-quality, approved silica. This material omits color additives to make it compliant with the most relevant food contact regulations globally, including U.S. Food and Drug Administration (FDA) regulations, European Food Contact Regulations (EC 1935/2004) and Chinese food safety standards (GB).

Alongside full compliance, FoodPro® HMF 48 is designed for strong performance in all operating conditions, is compatible with a wide range of foods and beverages and can withstand the harsh cleaning processes used in the food processing industry.

Advantages: Universal material for food processing – Compatible with food contact regulations – Suitable with all foods and cleaning processes

Alongside full compliance, FoodPro® HMF 48 is designed for strong performance in all operating conditions, is compatible with a wide range of foods and beverages and can withstand the harsh cleaning processes used in the food processing industry.

Advantages: Universal material for food processing – Compatible with food contact regulations – Suitable with all foods and cleaning processes