Concrete Pipeline Systems. Integrated & Pre-Lubricated Sealing Systems

Trelleborg's integrated sealing system was the first and original sealing system whereby the rubber seal is cast into the socket during pipe manufacture.

Until the early 1960’s sewerage pipelines were predominantly jointed using tarred yarn with a cement mortar fillet. To be successful, these joints greatly depended on the skill and diligence of the installer and when completed were totally rigid with no flexibility to allow for subsequent ground movement.

With the late 1960’s came the change from rigid joints to ‘flexible’, designed to accommodate straight draw, angular deflection and transverse shear load without leakage or failure of the joint.

In addition to meeting and exceeding the joint performance requirements, Trelleborg has always believed that in a pipeline installation trench, the work force need as much help from the manufacturers of the pipe and joint as possible. It is for this reason that our joint systems are designed to be as ‘fool proof’ and secure as possible.

Examples of this philosophy are Integrated Seal Joints

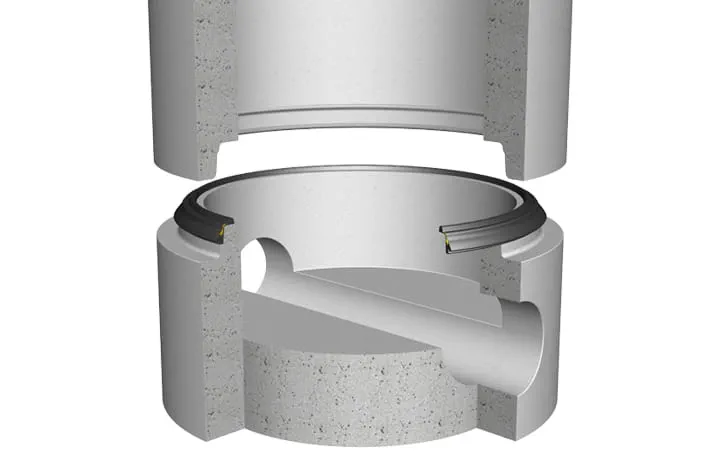

Trelleborg's integrated sealing system was the first and original sealing system whereby the rubber seal is cast into the socket during pipe manufacture. Advantages to the pipe layer include:

- No possibility of lost or missing seals

- No possibility of using the incorrect seal

- Always the correct seal in the correct position in the joint

- Increase laying speed

Integrated sealing systems can easily be used with mechanical pipe laying equipment reducing the need for operators in the trench, increasing installation speed and improving health and safety issues on site.

This philosophy also applies to Manhole joints where applying lubricant to the underside of a suspended load is an unnecessary risk.

Advanced seals are available incorporating an enclosed skin or mantle integrated onto the main sealing body, internally lubricated with silicone grease.

This makes centering the joint easier, removes the need for external lubrication, and reduces jointing force thus allowing assembly to be made under the self-weight of the manhole elements.

Our most advanced system, the Trelleborg 171, includes an integrated ‘Load Distribution’ elements which prevent concrete to concrete point loading through the manhole section joints and removing the risk of structural failure.