All Trelleborg sites

Close- Group Trelleborg is a world leader in engineered polymer solutions that seal, damp and protect critical applications in demanding environments. /seals-and-profiles/-/media/group/site-switch/trelleborg-group.jpg?h=264&w=293&rev=b3492bd026aa498f90103f0288dfc4e6&hash=4374E8706B9FEC077A21F603EE468A8F

- Antivibration Solutions Helping to remove unwanted vibration and noise in Rail, Marine, Off-highway and Industrial applications /seals-and-profiles/-/media/group/site-switch/antivibration.jpg?h=264&w=293&rev=cac94d89d97a4764937febb8422dbc03&hash=7B02E17EE232D4846ED337B40E88E8B4

- Boots Advanced dynamic protection for Automotive Driveshaft and Steering Gears /seals-and-profiles/-/media/group/site-switch/testing-boot-cold-1.jpg?h=264&w=293&rev=e398df5cfb7d4080a18fb803255e50bc&hash=DB31056F8D964D18114240D7DE875E17

- Damping Solutions Automotive noise damping shims & insulators /seals-and-profiles/-/media/group/site-switch/damping-solutions.jpg?h=264&w=293&rev=e4886fdb3c364d319c626e35fe923d04&hash=052A1B1378D12A2CF31F6BB97E99ABFC

- Engineered Coated Fabrics Trelleborg’s Engineered Coated Fabrics business unit, a world-leading producer of specialty polymer-coated and calendared materials, operates under the Coated Systems business area. /seals-and-profiles/-/media/group/site-switch/engineered-coated-fabrics.jpg?h=264&w=293&rev=2fdac9be0f434313920fb532c7262a43&hash=110C1A832F092CA59204E1F9098F3ED2

- Fluid Handling Solutions Industrial Hose, Expansion Joint, Oil & Marine Hose, Rubber Sheeting and Mining Applications /seals-and-profiles/-/media/group/site-switch/fhs.jpg?h=264&w=293&rev=6cf337a4c82642b59e004d0a9199ea15&hash=B56A63E775AE0FE876E97A916D58B0D6

- Medical Solutions Supporting the Healthcare and Medical industry with advanced polymer engineered components /seals-and-profiles/-/media/group/site-switch/healthcare-and-medical.jpg?h=264&w=293&rev=627ac8af44794afb8aa913220f959254&hash=1AAC4CE8C8F331DDEE9CBA2C6A978D17

- Marine & Infrastructure Highly engineered polymer solutions for marine and civil infrastructure /seals-and-profiles/-/media/group/site-switch/marine-and-infrastructure.jpg?h=264&w=293&rev=b209d371ac264b6f85b7b8167ef0860c&hash=24D436ECFAFBE97129215CA4C145E05A

- Sealing Solutions Sealing and bearing solutions for Industrial, Automotive and Aerospace applications /seals-and-profiles/-/media/group/site-switch/sealing-solutions.jpg?h=264&w=293&rev=158324dc66494c6a8450812cbd4a794b&hash=FEBD09F5D87A0C896BB88A5CD2685669

- Seals & Profiles Seals for applications in buildings and construction, aerospace, automotive, agriculture, renewable energy and water infrastructure. /seals-and-profiles/-/media/group/site-switch/seals-and-profiles.jpg?h=264&w=293&rev=c630d927a2a9455e851bb1a4fd6da61e&hash=FF57CA327CDC0A9BE5452EE2CC52A99C

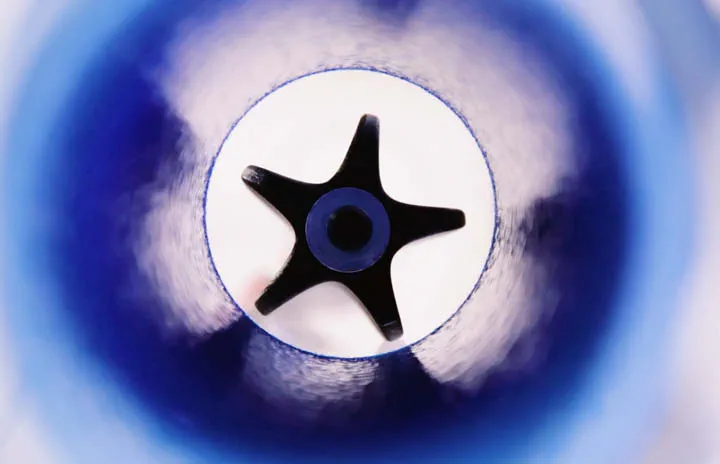

Pipe coating technology

The revolutionary Spraypoxy Pipe Coating system for the economical rehabilitation of even smaller pipe cross-sections. Pipe coating without the use of liners. Especially in the in-house area, in narrow conditions, for small and difficult-to-access sewage pipes and stachpipes in the nominal width range DN 32 to DN 150.