Shaft Power Meters: cost-effective tools for measuring efficiency

Through real-time measurement of surface strain, shaft torque and power are calculated. The direct measurement of shaft power provides an early indication of increasing power requirements that cannot be identified through theoretical calculations derived from test house power curves.

When comparing performance against base line data, shaft power meters can provide an early indication of any degradation in operating conditions by highlighting increasing power usage that leads to increased fuel consumption and ship emissions, and higher operating expense (OPEX).

A shaft power meter is a critical hardware component for any ship performance monitoring system. Shipowners are deploying these monitoring systems to help improve ship operating efficiencies and to create automatic reports. When combined with fuel consumption and ship speed, the power readings can be used for reporting hull, ship, and fuel efficiencies, as well as data for Energy Efficiency Operational Index (EEOI) and ISO19030 reporting.

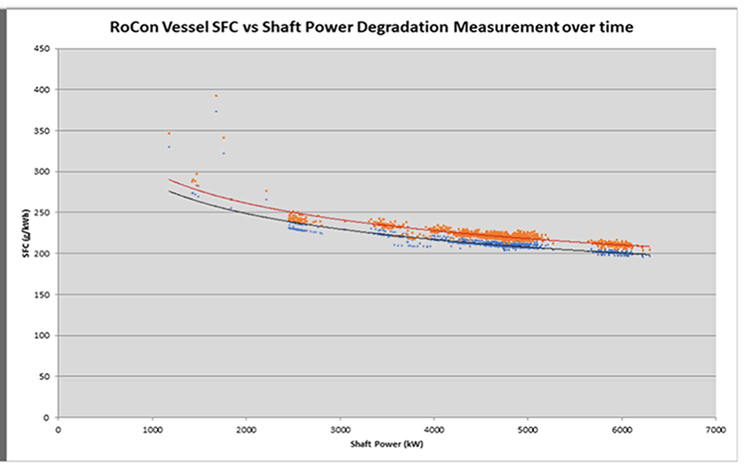

Graph 1 shows the corresponding fuel consumption versus ship speed for the same RoCon vessel. As shown in the graph below, the fuel consumption increases as the engine load increases in order to generate the same power output. In this case, increases of 4% to 6% in power output and fuel consumption were observed.

By generating these reports, shipowners can make data-driven decisions on when to clean hulls and propellers, avoiding excessive fouling, while lowering fuel consumption and reducing engine emissions. This in turn lowers OPEX while providing a quick return on investment.

Hull Fouling

Severe hull and propeller fouling are major concerns for shipowners, potentially increasing fuel consumption and engine emissions by over 50%. With a shaft power meter fitted, the effects of fouling can be spotted early, and preventive action taken quickly. Additionally, it allows for the before and after-effects of any anti-fouling technologies, applied to the hull or propeller, to be monitored accurately to measure their effectiveness.

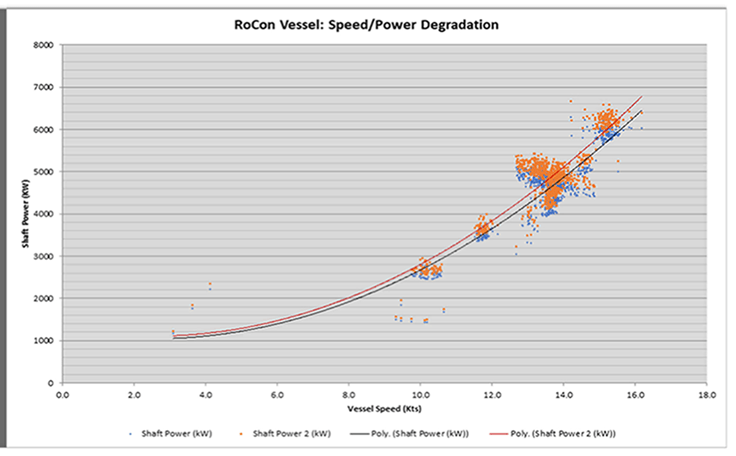

Graph 2 shows power versus speed for a large RoCon vessel operating in the Middle East. The blue and orange dots represent power/speed measurements taken over fixed periods of time and indicate how the ship has to use more power over time to maintain the same speed, as the hull and propeller become fouled.

Strain Gauge Technology

Installed on over 700 ships, Trelleborg’s TSX5 Shaft Power Meter is a well proven system that can be fitted to a wide range of shaft sizes, from 150 mm to 1000 mm.

The TSX5 Shaft Power Meter utilizes strain gauge technology applied to the surface of the intermediate shaft and considered to be the most accurate method of calculating torque. The engine and gearbox apply torque to the shaft, while resistance from the propeller applies drag. The combination of torque and resistance twists the shaft, causing surface strain to increase and the strain gauge to deform, resulting in a change in its electrical resistance, from which an accurate measurement of strain is calculated.

The change in resistance from the strain gauge is measured by a rotor board unit, which is housed in the rotor ring clamped to the shaft. Additionally, the rotor ring protects the strain gauge from damage. The rotor board unit conditions and processes the information from the strain gauge and then wirelessly transmits the signal to a processing cabinet, adjacent to the shaft, for calculating shaft torque and power.

Remote display panels mounted in the engine control room (ECR) or bridge report shaft power, torque, rpm, and shaft direction. Thrust can also be measured by fitting additional strain gauges. The TSX5 system can also be interfaced to the ship’s DCS and IAS, and to an independent ship performance monitoring system.

EEXI Compliance

On 17 June 2021, the International Maritime Organisation (IMO) adopted amendments to MARPOL Annex VI at MEPC 76, introducing regulations 23 and 25 - the Efficiency Existing Ship Index (EEXI), which are the first steps for the shipping industry to move towards its target of a 50% reduction in carbon emissions by 2050.

All existing ships must achieve a required EEXI score, with the target score dependent on the type of ship. The initial work to be carried out by each ship is to calculate it’s attained EEXI score, in accordance with MEPC.333(76), and to establish if it meets the required EEXI score. If it does not, then the ship must take action before compliance is demonstrated. Compliance has to be demonstrated in accordance with MEPC.334(76), on or after 1 January 2023 at the date of the IAPP survey and during the annual, intermediate or renewal survey, whichever comes first.

Two methods have been prescribed by the IMO that the ship can take to improve its EEXI score for the main engines in accordance with MEPC.335(76): Engine Power Limitation (EPL) and Shaft Power Limitation (ShaPoLi).

The ShaPoLi method involves the measurement of shaft power, torque and speed that are fed back to the engine management system to then limit power in accordance with the regulations. The ShaPoLi method will most commonly be required for four-stroke engines with multi consumers where limiting engine power using the EPL method will result in power being reduced to all consumers, which would not be acceptable. By measuring shaft power to the propeller and limiting only this consumer then the ship can comply with EEXI requirements, whilst the rest of the configuration keeps its original profile.

Trelleborg’s TSX5 Shaft Power Meter can form part of an EEXI compliant ShaPoLi system in accordance with the requirements of MEPC.335(76).

Decarbonizing the Maritime Sector Through the Development of Clean Technology

As the shipping industry moves forward towards a more sustainable future, improving energy efficiency, reducing fuel consumption, and lowering greenhouse gas emissions are becoming critical for ship owners. With the EEXI rules coming into force, the industry is looking for solutions that can assist with this transition. A shaft power meter is one solution shipowners can adopt now.

Being an accurate measurement of power to water, a shaft power meter in its own right will allow efficiency savings to be identified and hull fouling effects to be spotted early. As part of a ship performance monitoring system, it becomes a more sophisticated tool allowing a variety of efficiencies to be calculated that can allow ships to reduce fuel consumption and greenhouse emissions. When included in a ShaPoLi EEXI compliance system a shaft power meter forms a key component allowing multi consumer engines to easily comply.

With a firm belief that prioritizing sustainability above everything is the right thing to do, Trelleborg’s marine and infrastructure operation is committed to supporting five of the United Nation’s goals, including that of SDG 7: Affordable and Clean Energy and SDG 13: Climate Action SDG 9: Industry, innovation and infrastructure, which relates to Trelleborg’s sustainability focus areas of decarbonization of the maritime sector through the development of cleantech and premium product design.

Taking a smarter approach to the optimization of marine operations powered by technological innovation to deploy cutting-edge smart engineered solutions, Trelleborg’s SmartPort portfolio enhances the efficiency and reduces the carbon emissions of vessels and port operations.

Trelleborg’s SmartPort enabled TSX5 Shaft Power Meters can be incorporated into all of these applications and has a proven track record of over 20 years of helping shipowners to achieve energy efficiency savings.